Ready to dive deeper into the world of steel coils? Let’s join us on a journey of steel coil discovery with this article now!

-

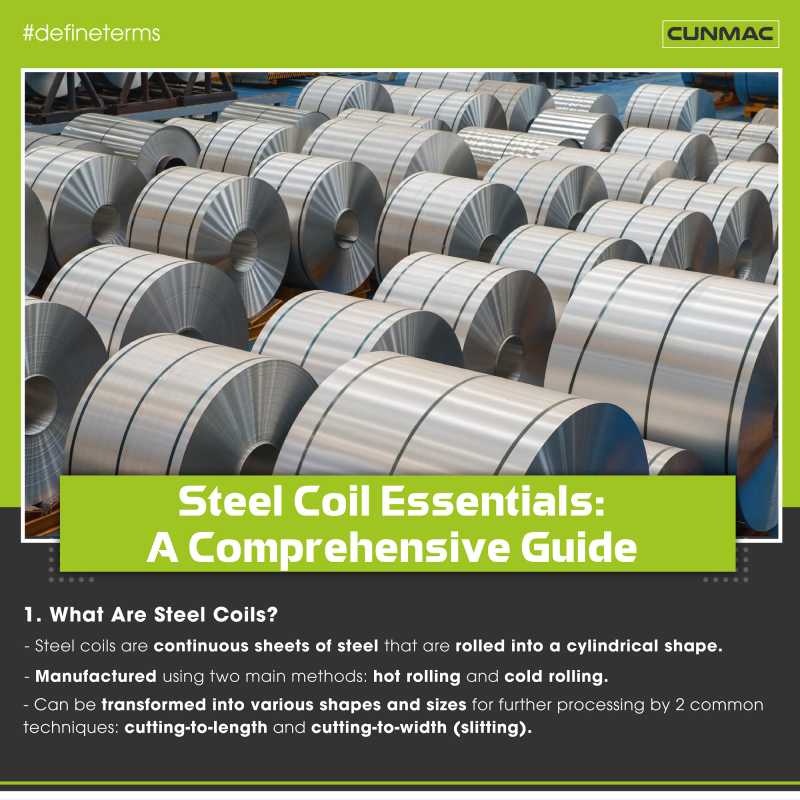

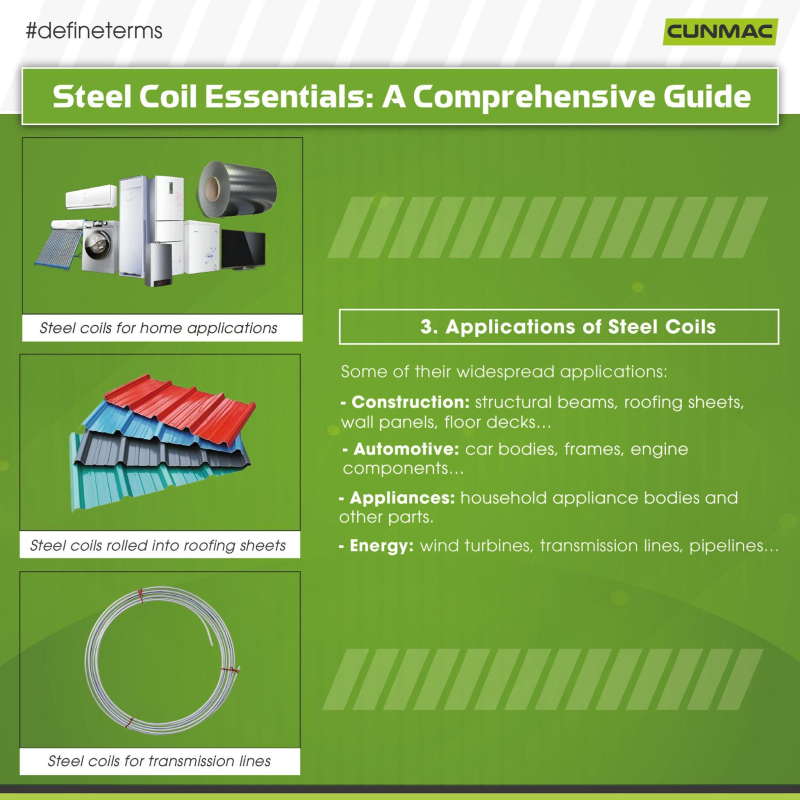

What are steel coils?

Steel coils are continuous sheets of steel that are rolled into a cylindrical shape. They are manufactured using two main methods: hot rolling and cold rolling. Steel coils are often transformed into various shapes and sizes for further processing by 2 common techniques: cutting-to-length and cutting-to-width (slitting).

Steel coils in cylindrical shape

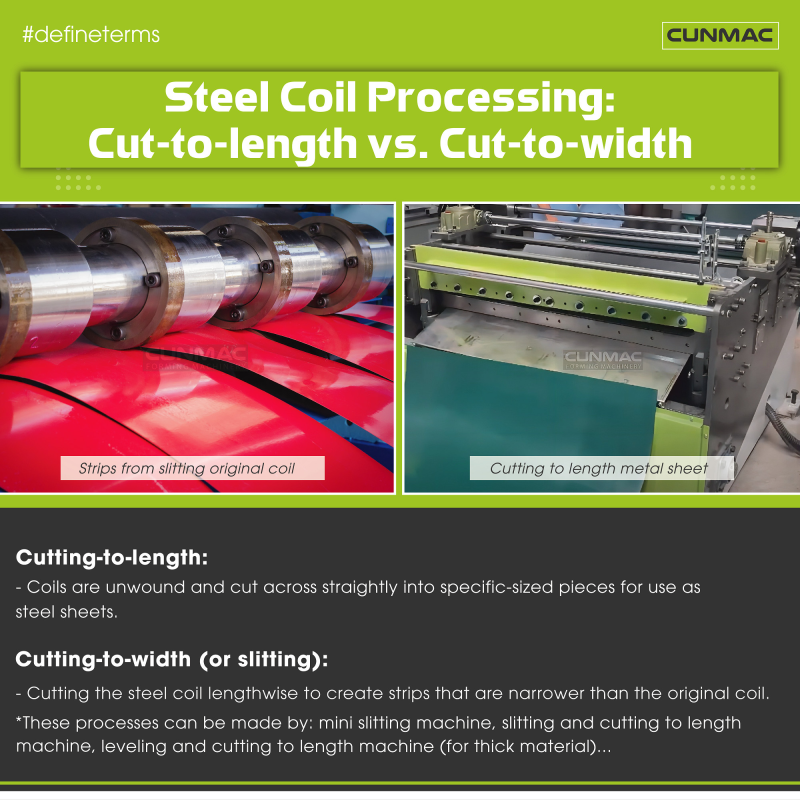

Cutting-to-length and Cutting-to-width (slitting) in comparison:

Cutting-to-length: Coils are unwound and cut across straightly into specific-sized pieces for use as steel sheets.

Cutting-to-width (or slitting): Cutting the steel coil lengthwise to create strips that are narrower than the original coil.

Cutting to length and Cutting to width (slitting)

These processes can be made by: mini slitting machine, slitting and cutting to length machine, leveling and cutting to length machine (for thick material)…

Slitting and cutting to length machine

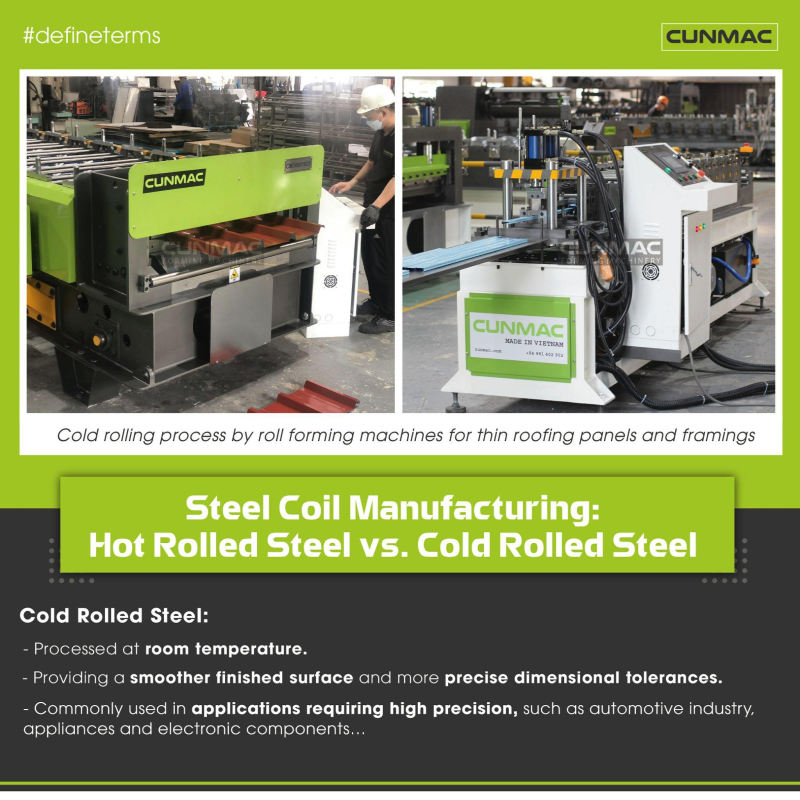

Hot Rolled Steel and Cold Rolled Steel in comparison:

| Hot Rolled Steel | Cold Rolled Steel |

| – Produced by heating above steel’s recrystallization temperature. – Having a rougher surface and a larger range of dimensional sizes. – Most commonly used in construction and manufacturing, particularly when a thicker steel coil is required. – Lower cost and faster production time make it a popular choice for large-scale projects. | – Processed at room temperature. – Providing a smoother finished surface and more precise dimensional tolerances. – Commonly used in applications requiring high precision, such as automotive industry, appliances and electronic components… |

Hot rolled steel and Cold rolled steel

-

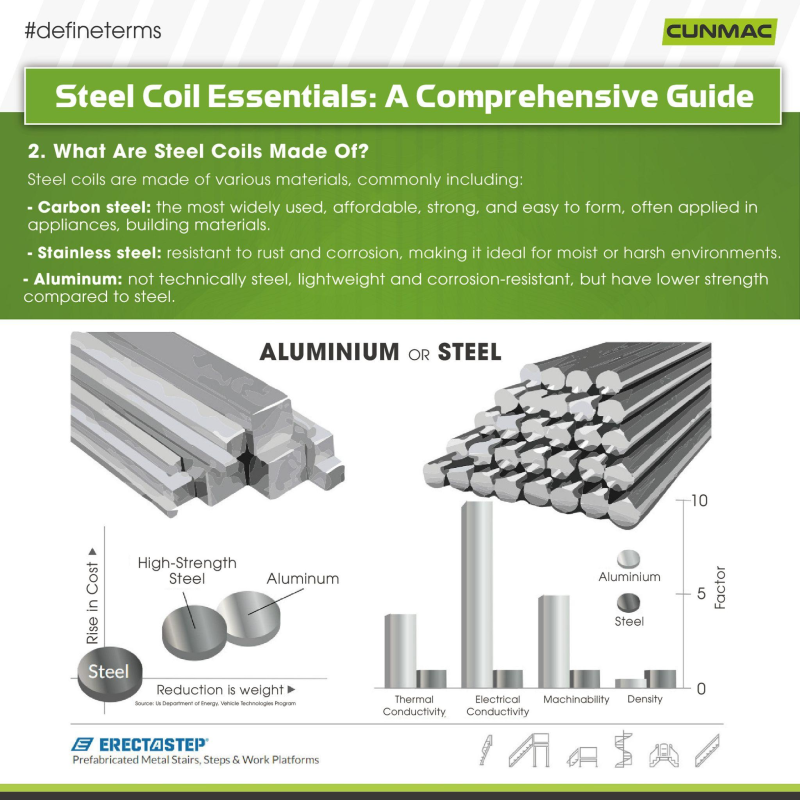

What are steel coils made of?

Steel coils are made of various materials, commonly including:

– Carbon steel: the most widely used, affordable, strong, and easy to form, often applied in appliances, building materials.

– Stainless steel: resistant to rust and corrosion, making it ideal for moist or harsh environments.

– Aluminum: not technically steel, lightweight and corrosion-resistant, but has lower strength compared to steel.

Channel roll forming machine of CUNMAC with 2 options:

standard with no safety cover (left) and special with safety cover (right)

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.