Looking for the perfect roll forming machine for your roofing project? Let’s check out our overview of the most common types of roll forming machines to make an informed decision.

1. Standard roofing roll forming machine

Also known as trapezoidal/rib type/spandek/trimdek/4 angles/waves roofing machine, creates IBR roofing panels from metal/steel sheets.

Can produce various rib-type profiles for residential or industrial use, such as 4 – 5 – 6 – 7 – 9 – 11 – 13-ribs profiles.

Commonly used in residential and industrial projects, a popular choice for factory owners starting their own roof factory or construction material business.

Standard roofing roll forming machine

2. Corrugated roofing roll forming machine

Corrugated roofing roll forming machine produces corrugated metal roofing sheets widely used for roofing, wall cladding, fences, and screens in various applications including:

- Household constructions: houses, kiosks, shops…

- Industrial workshops: warehouses, factories, offices…

- Public buildings: hospitals, schools, departments…

Corrugated roofing roll forming machine

3. Tile roofing roll forming machine

A step tile roofing roll forming machine or roof tile making machine shapes metal sheets into tile roofing sheets using rollers and a pressing system.

Glazed Tile Roll Forming Machine produces various profiles: Classic tile, Master tile, Ruby tile, Roman tile, Wood tile and so on.

Investing in a rib type roll forming machine is often followed by a tile roll forming machine to create metal tile roofing, as it offers higher aesthetics for villas or penthouses.

Tile roofing roll forming machine

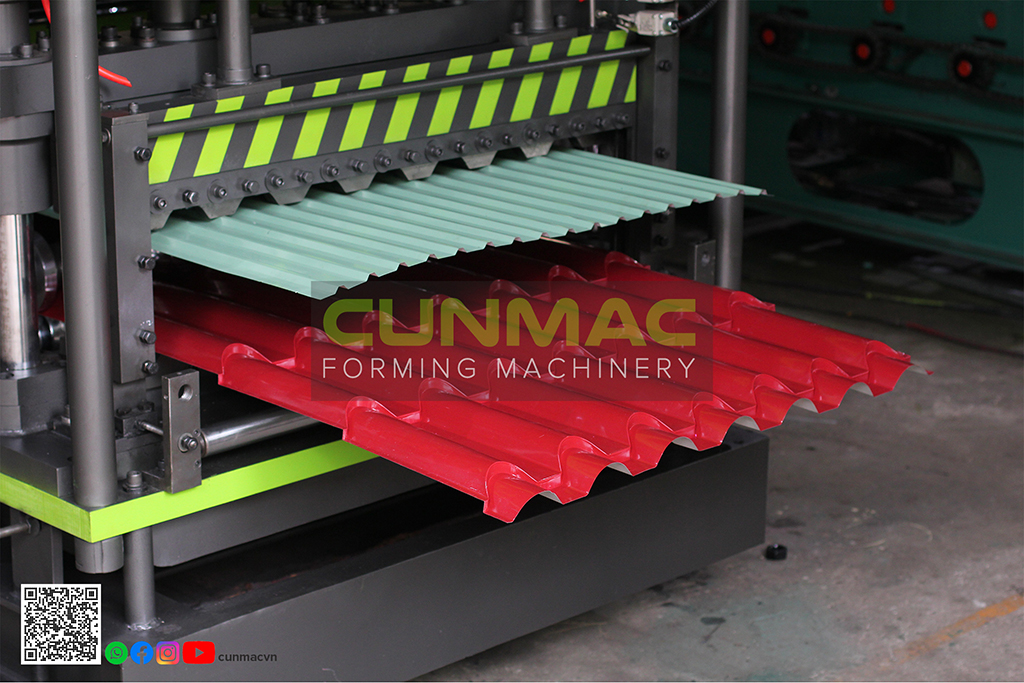

4. Double layer roll forming machine

Also known as a dual level roll forming machine/double deck roll forming machine, or 2 in 1 double deck roofing sheet machine, has two layers of roll forming parts that can produce two metal sheets.

The Double Deck roll Forming machine will usually be combined as:

- One trapezoidal roofing and one roof/wall cladding sheet;

- One trapezoidal roofing sheet and one corrugated roofing sheet;

- One trapezoidal sheet and one metal roof tile;

- One corrugated sheet and one metal glazed roof tile etc.

Double deck machines are commonly used because they can save your space and save your budget with 2 profiles in 1 machine.

Double layer roll forming machine

5. Seamlock roll forming machine

Also known as standing seam roll forming machine, manufactures metal roofing looks terrific and can handle a wide range of conditions well. Proper ventilation and an air gap between the roof and the decking must be carefully designed, however, a properly installed standing-seam roof will last for several decades.

Seamlock roll forming machine

6. Portable roofing roll forming machine

A particular design of a roll shaping machine that is simply on a consolidated level and handles everything a common machine does. However, simply pack it into a more modest size so it will move without any problem.

This machine does everything a typical metal roll former does, just in a smaller and more condensed size for easier transportation and work at job sites.

Portable roofing roll forming machine

Through this post, CUNMAC team has given you common types of roofing roll forming machine. Don’t forget to follow the next issue of our series #defineterms to update more useful information.

This series belongs to CUNMAC Vietnam.

CUNMAC Vietnam – Roll Forming Machine Manufacturer has 15 years experience to ensure machine quality and customer satisfaction all over the world.

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.