What is a batten/tophat/hat channel roll forming machine?

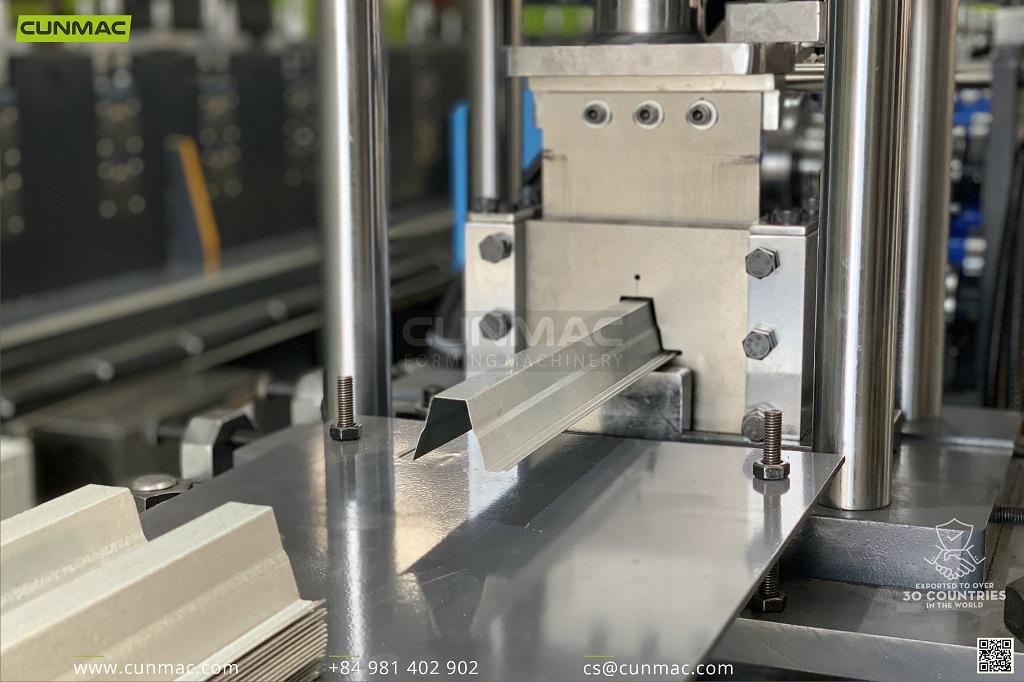

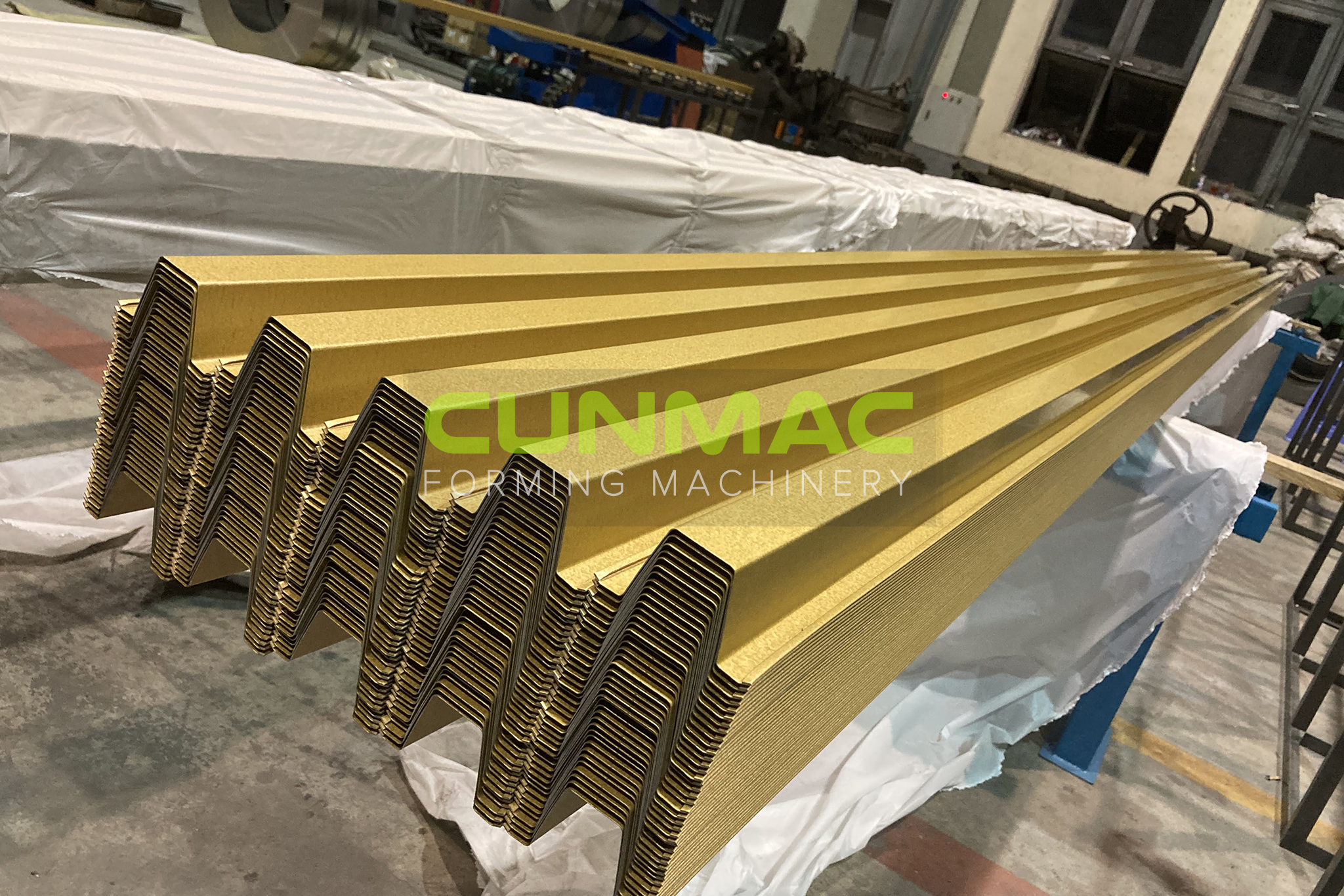

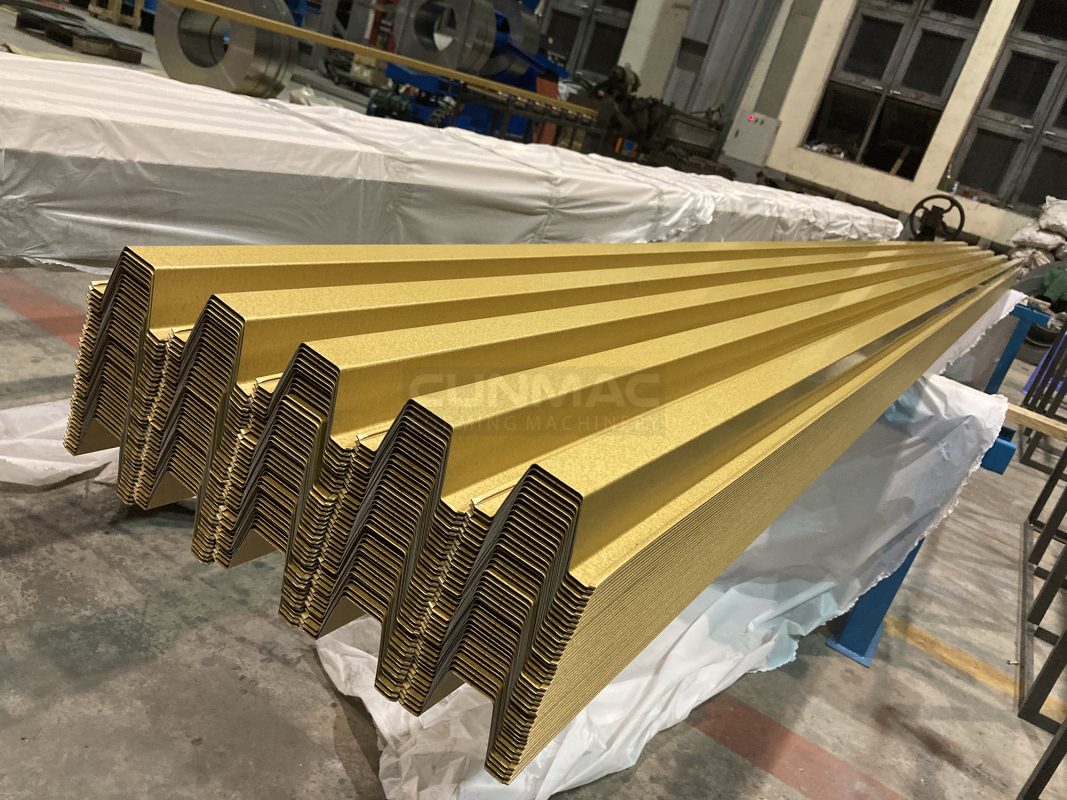

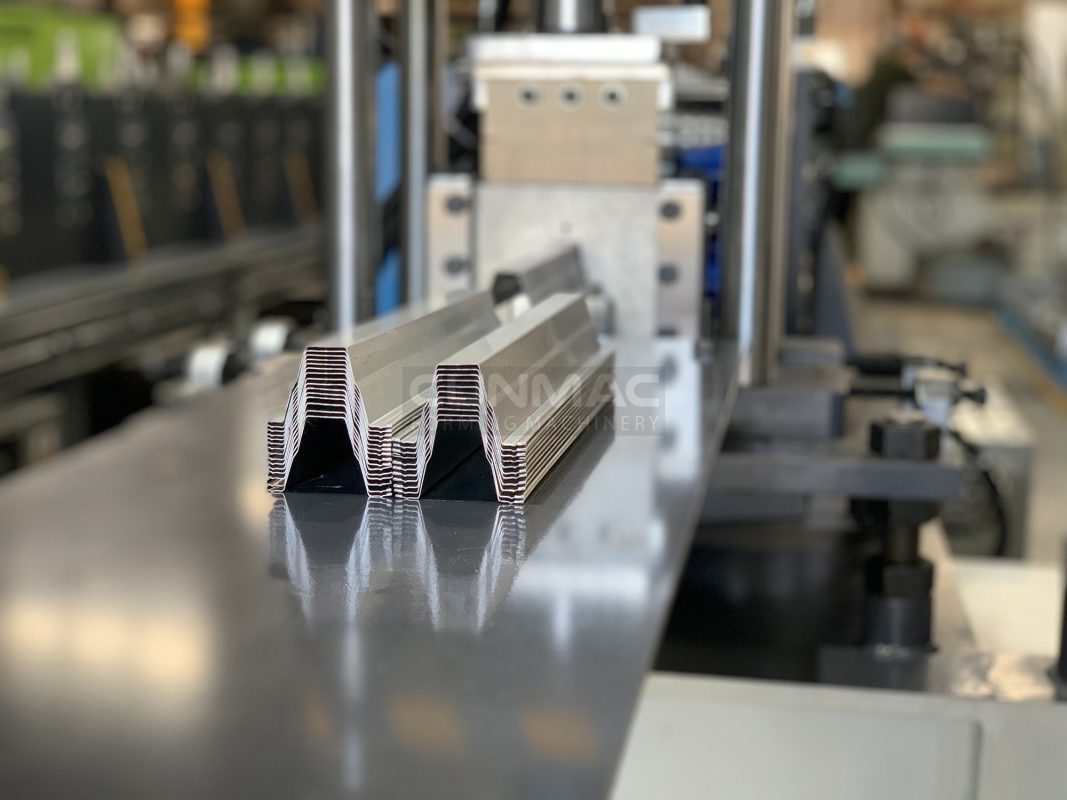

Batten roll forming machine, also known as a Top hat channel/ Hat channel/ Furring channel/Topspan roll forming machine, is commonly used in constructions, particularly for roofing framing applications. The HAT profiles offer structural stability, strength, and versatility, making them a popular choice in modern building projects with various applications of batten/tophat frames: framing systems, roof trusses, wall studs, and suspended ceilings.

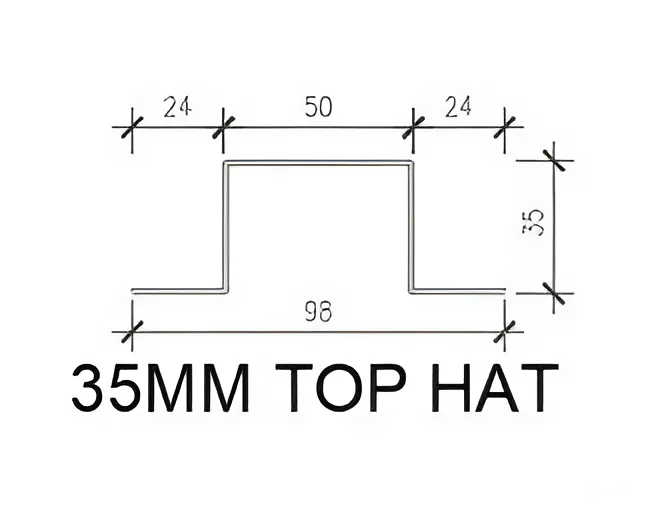

Common 35mm Top Hat

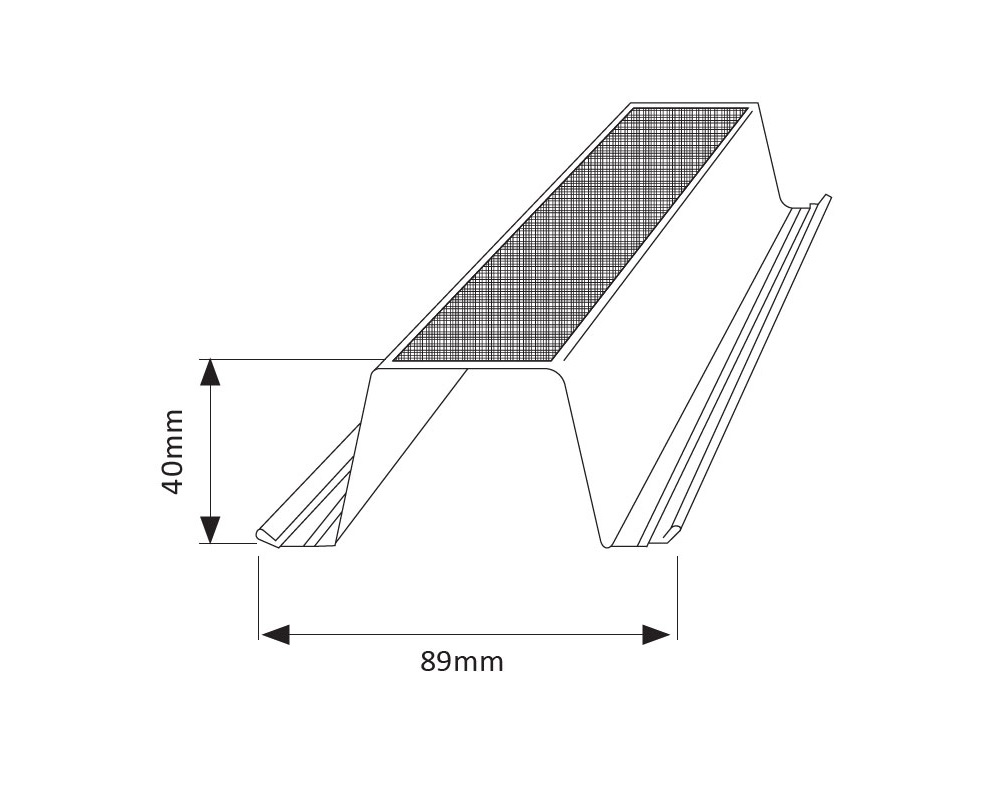

40mm Ceiling Batten

Top hat channels and applications in truss framing

<p “>Batten roll forming machine is capable of processing various types of metals, including steel, aluminum, and galvanized steel, with different thicknesses and widths. They are highly automated and can produce profiles at a high production rate (up to 60 m/min), making them efficient for large-scale manufacturing.

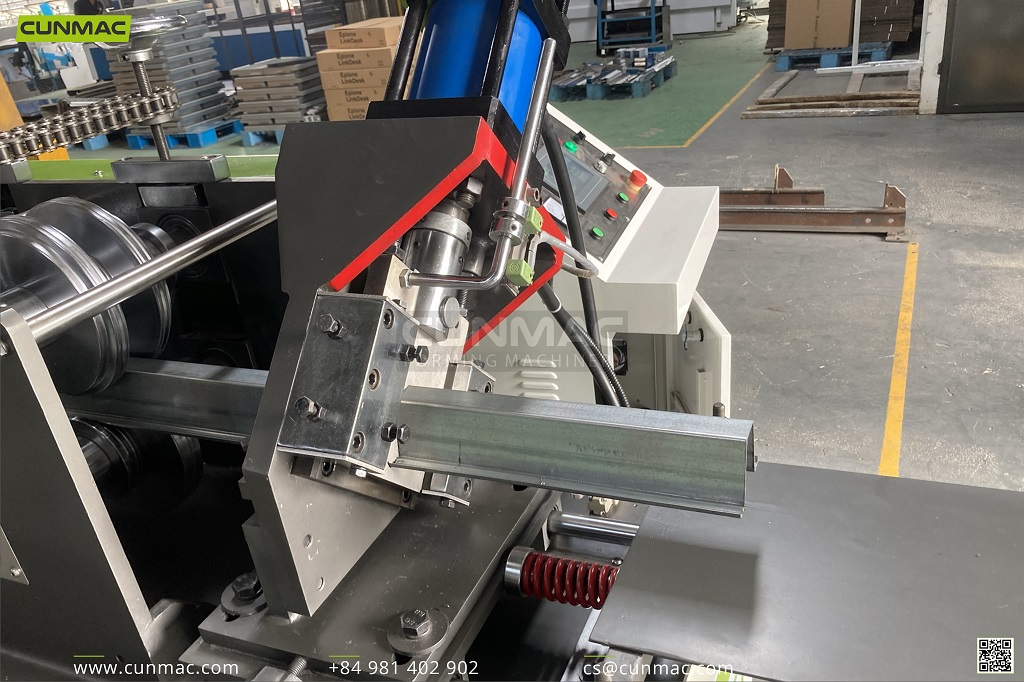

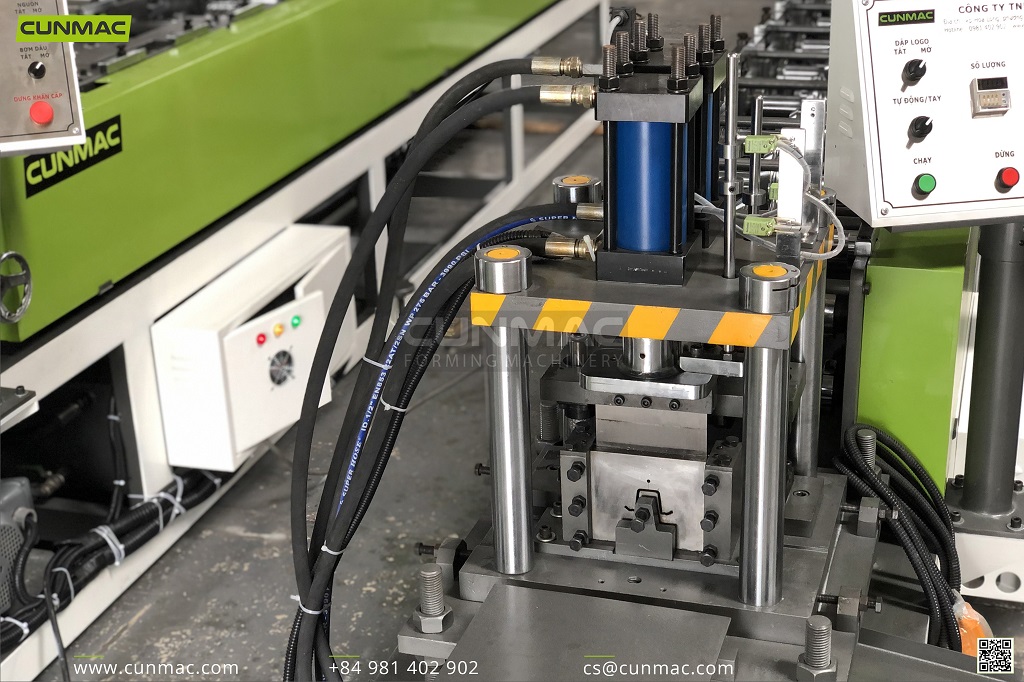

Batten/Hat channel roll forming machine with material thickness 1.0mm – CUNMAC Vietnam

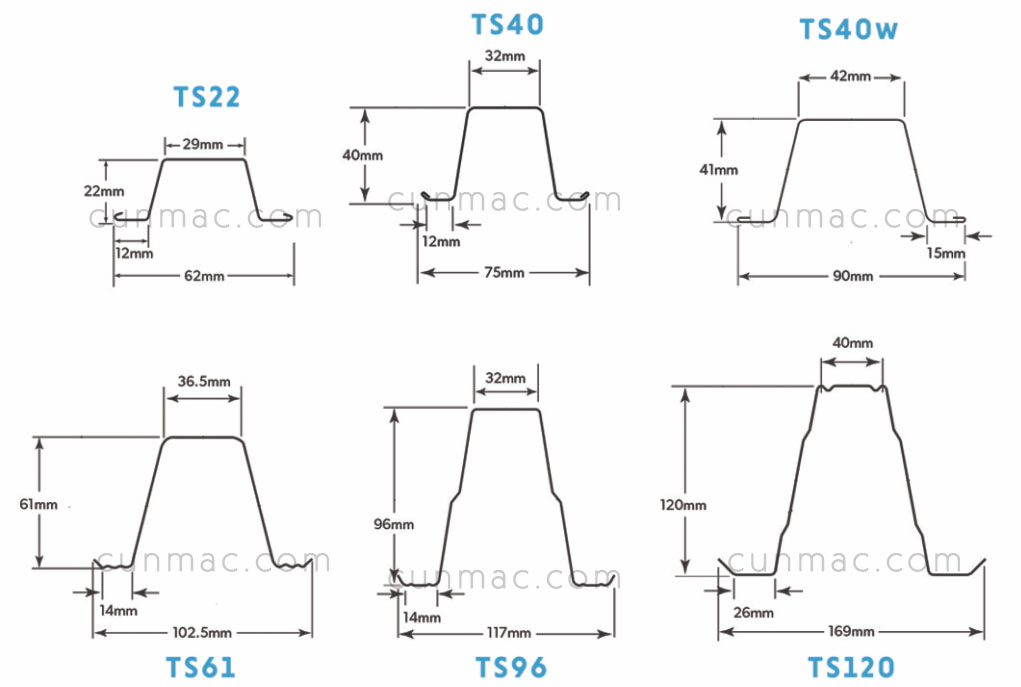

<p “>Read more: Truss roll forming machineWith our expertise team, CUNMAC is able to customize machines to suit any customer profile and specific requirements. Some common types of top hat profiles can be produced by CUNMAC batten roll forming machines:

Read more: Shipment of top hat roll forming machine to customer in Australia

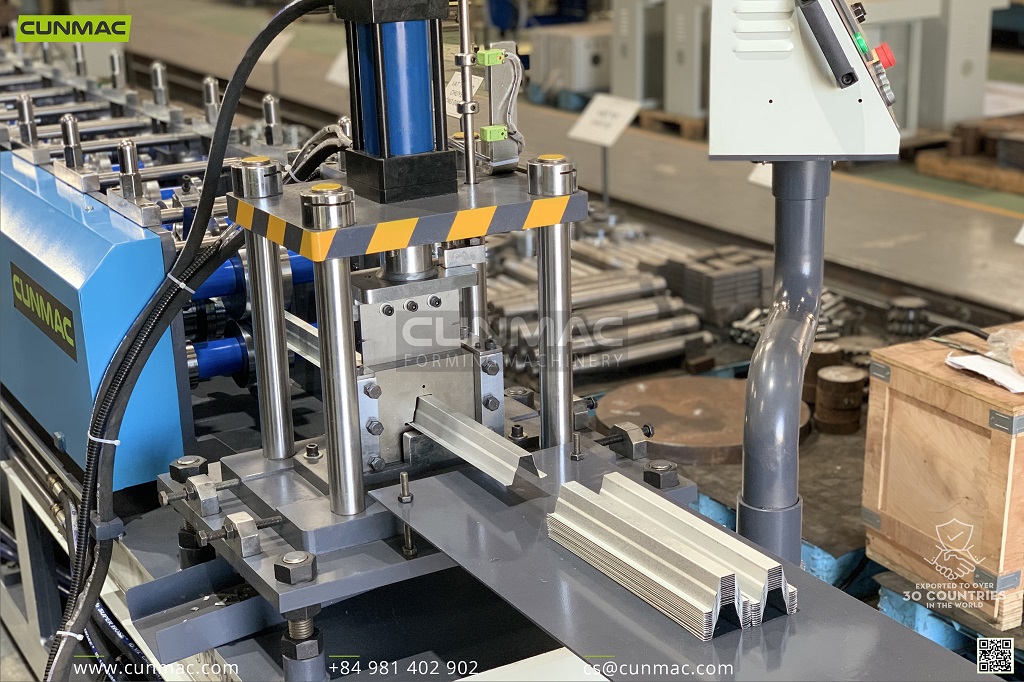

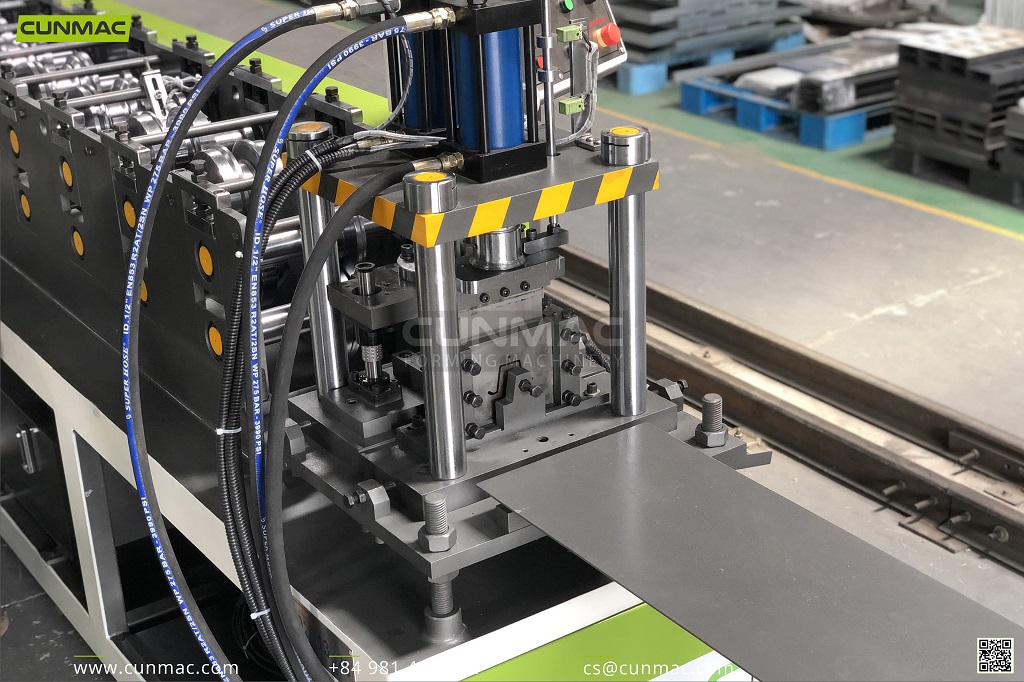

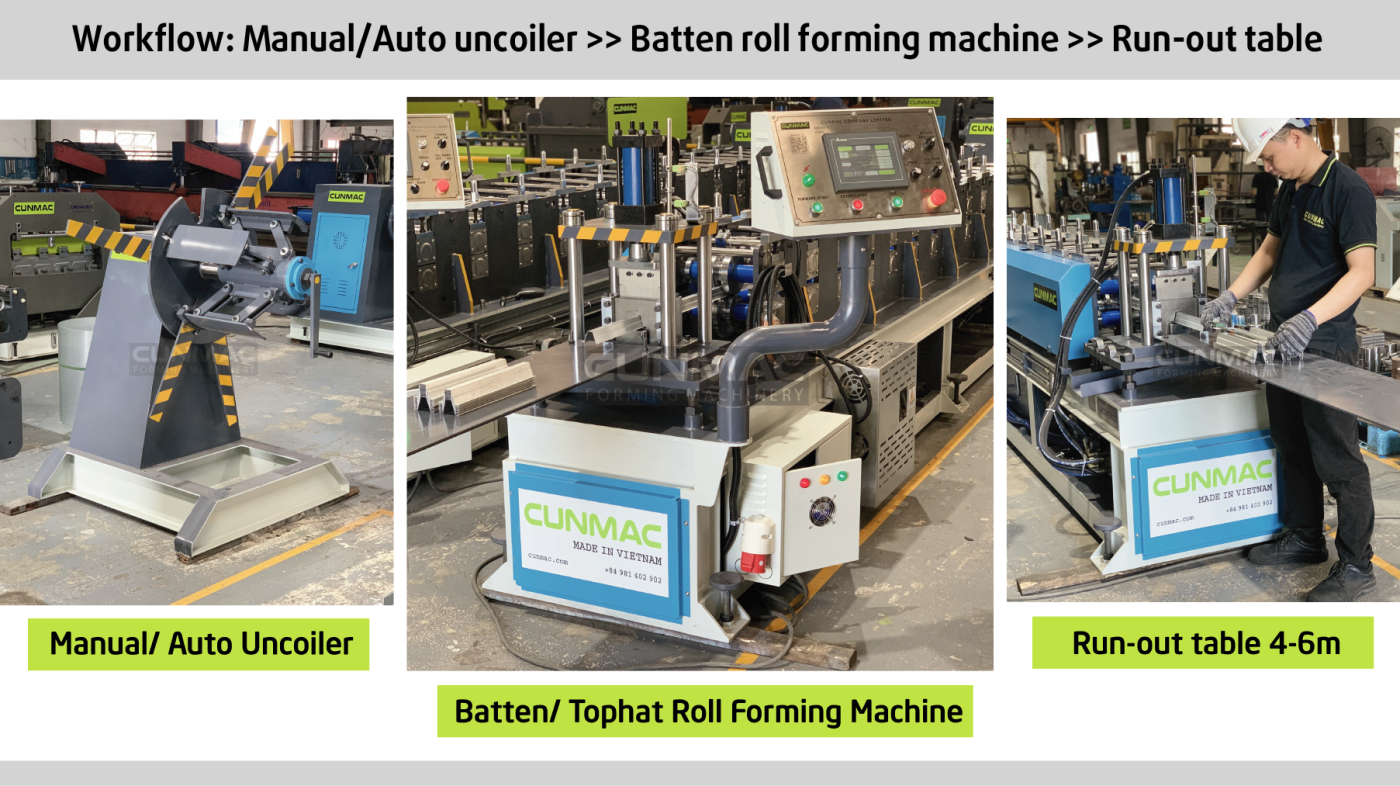

Batten roll forming machine is fully automatic and is easy to operate with Inverter, PLC, HMI. Their main advantages are beautifully customized designs, easy and stable operation with a strong body frame, and reasonable price.

Besides the standard option, CUNMAC also offers the option of a combined 2 in 1 roll forming machine, a worth-considerable choice with its great features such as cost-efficiency, flexibility in combined profiles and

Standard batten/ tophat machine (left) – Combined 2-in-1 batten/ tophat machine (right)

Read more: Combined roll forming machine

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 3.5 – 5.5kw | 5.5 – 7.5kw | 7.5 – 11kw |

| Speed | 12 – 18m/min | 24 – 30m/min | 54 – 60m/min |

| Dimension (LxWxH) | (3-5)x(1.2-1.4)x1.4m | (4-6)x(1.2-1.4)x1.4m | (4-8)x(1.2-1.4)x1.4m |

| Weight of machine | 2.5 – 4 tons | 3 – 6 tons | 3 – 6 tons |

| Roller station | 10 – 12 | 10 – 16 | 12 – 18 |

| Material thickness | 0.35 – 0.6mm (G300-G550) | 0.35 – 0.6mm (G300-G550) | 0.35 – 0.6mm (G300-G550) |

| Material width | 100 – 200mm | 100 – 200mm | 100 – 200mm |

| Transmission system | Hydraulic motor | Hydraulic motor | Gear motor |

| Cutting system | Hydraulic cylinder (front cutting) | Hydraulic cylinder (front cutting) | Hydraulic cylinder (front cutting) |

| Control system | Automatic with sensor | Automatic with PLC, HMI | Automatic with PLC, HMI, Inverter |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

CUNMAC products reach 10% of their sales in the domestic market (Vietnam) and 90% are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

Cunmac proudly provides Batten (reng) roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

We offer a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.