What is a portable roofing roll forming machine?

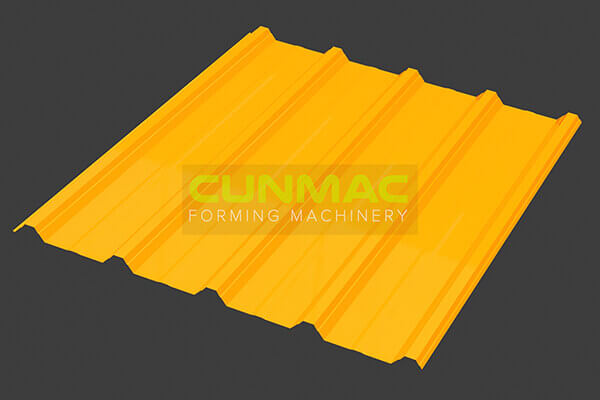

Metal rollforming describes the process of feeding metal through a system of rollers where each roller station further manipulates the metal into a particular profile

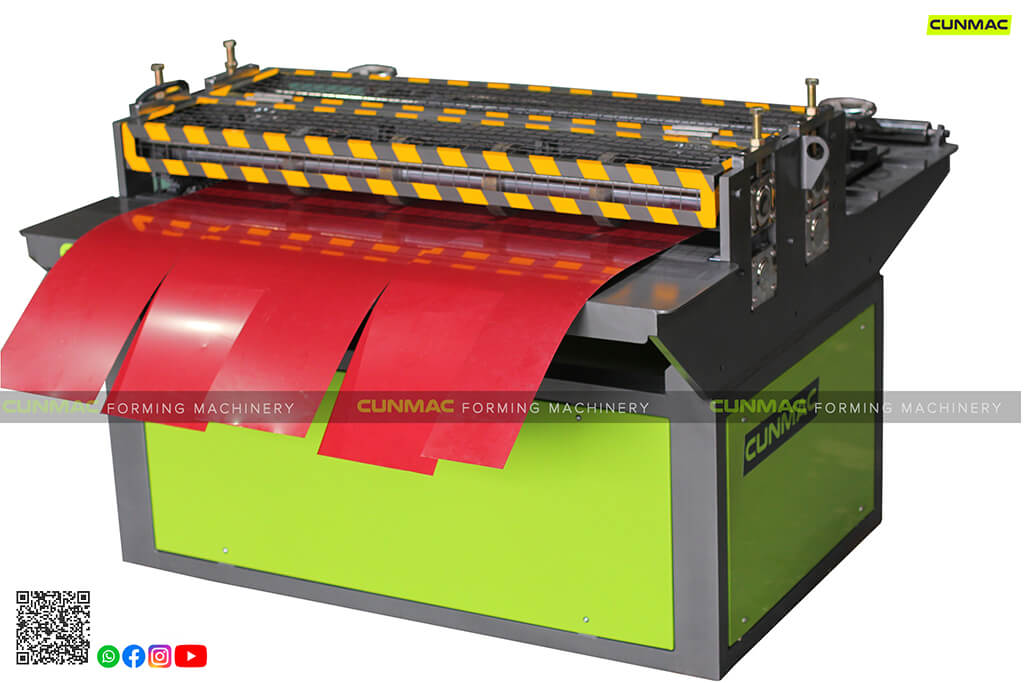

A portable roll forming machine is a particular design of a roll shaping machine which simply on a consolidated level and handles everything a common machine does. However, simply pack it into a more modest size so it will move without any problem.

Portable roll forming machines do everything a typical metal roll former does, just in a smaller and more condensed size for easier transportation and work at job sites.

Out-standing advantages:

Portable: the machine can be taken to any place of work

Save time: you can create any length of the item hands-on location, not have to set up a timetable.

No need for transportation of sheets: all the sheets will be delivered to the gathered site and furthermore, assemble directly

Machine accessibility & versatility: With the best possible lifting system, versatile machines can be lifted to the height of a structure’s rooftop if required.

Ceaseless work: the installers can constantly assemble the panels because sheets are produced on-site.

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

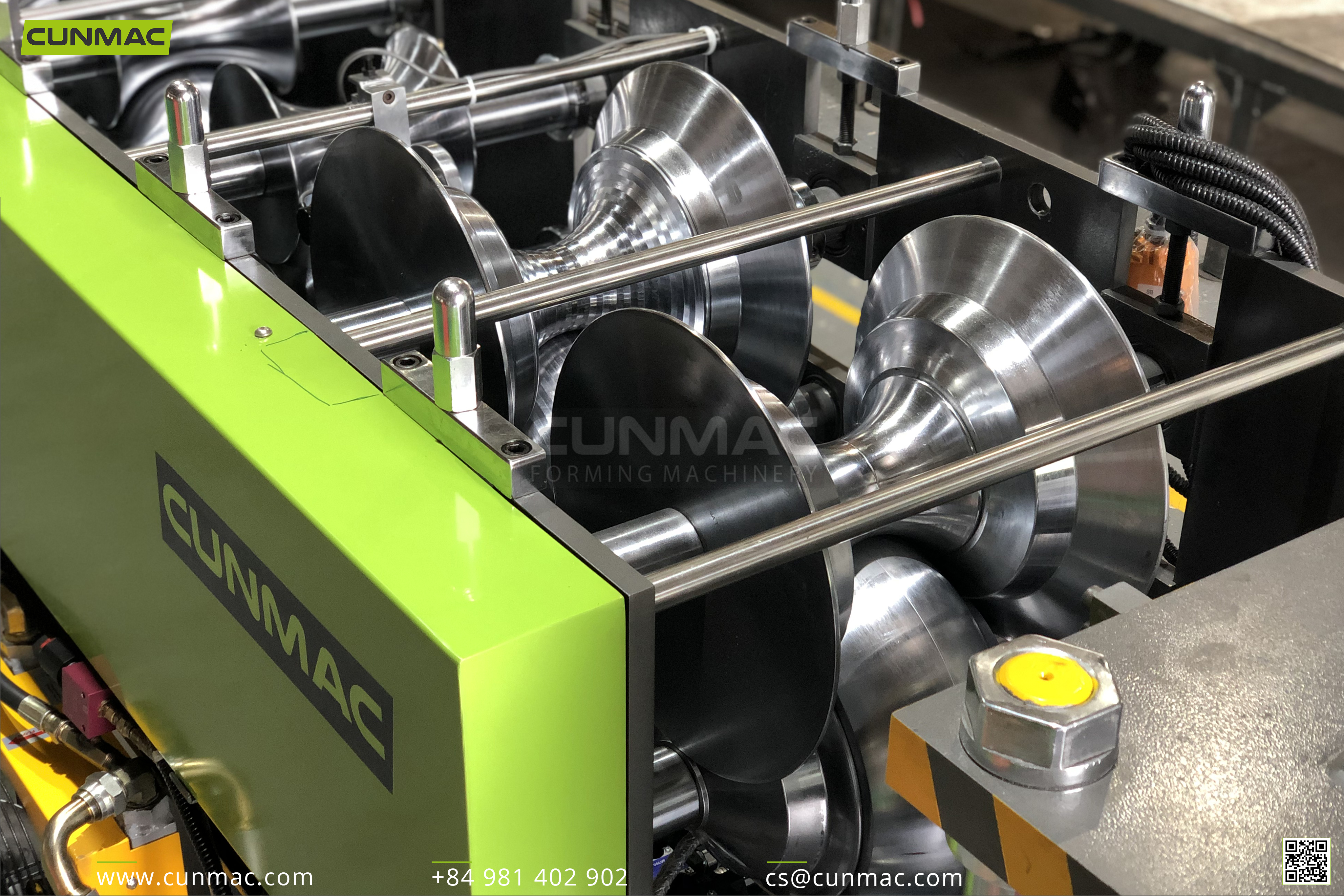

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 3.7 – 5.5kw | ||

| Speed | 16 – 18m/min | ||

| Dimension (LxWxH) | (4-6)x(1.1-1.6)x1.2m | ||

| Weight of machine | 3.5 – 5 tons | ||

| Roller station | 8 – 12 | ||

| Material thickness | 0.2 – 0.35mm (G300-G550) | ||

| Material width | 914; 1200; 1219; 1450mm | ||

| Transmission system | Hydraulic motor | ||

| Cutting system | Hydraulic cylinder (front cutting) | ||

| Control system | Automatic with PLC, HMI | ||

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

Cunmac proudly provides Portable roofing roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.