DETAILS INFORMATION

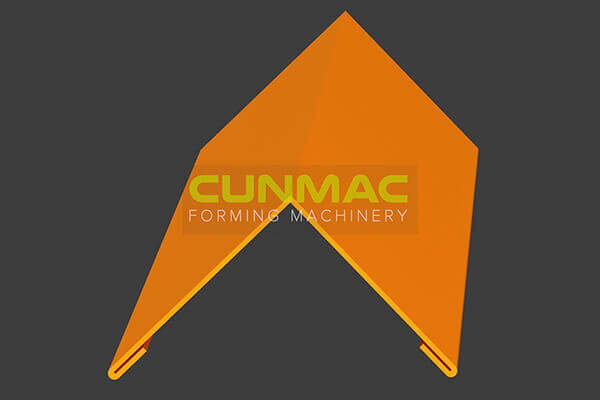

Metal framings used in concealed grid gypsum ceiling of light weight structure include furring channel, carrying channel, studs, tracks, wall angle, and main frame channel.

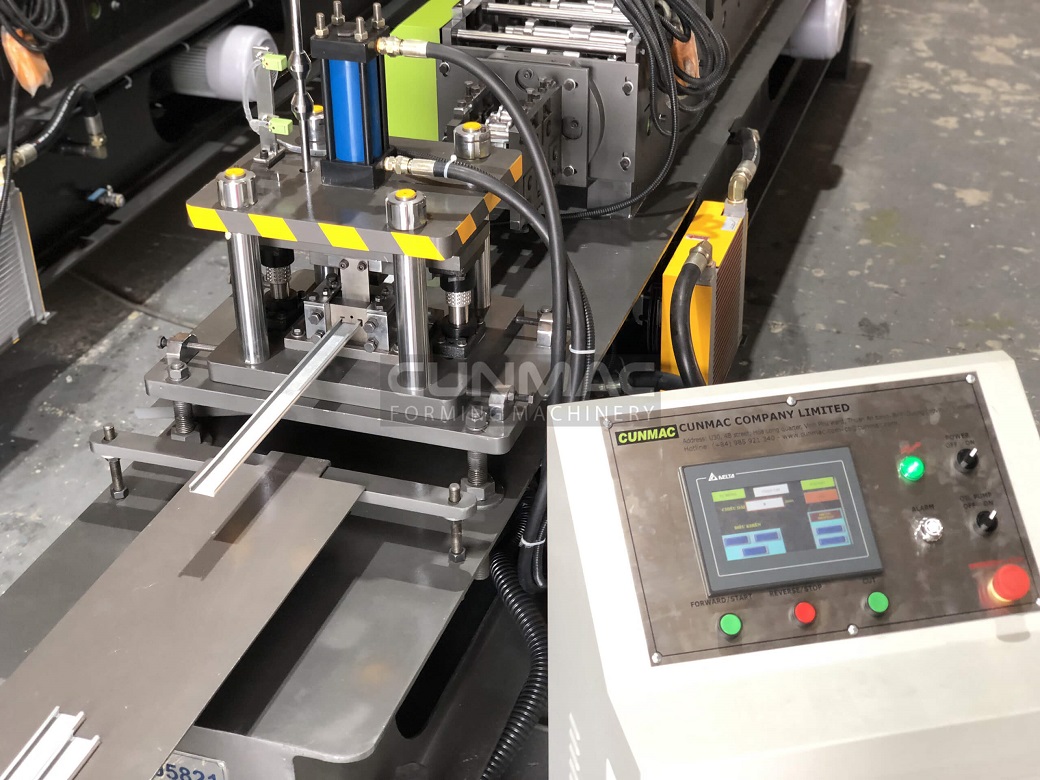

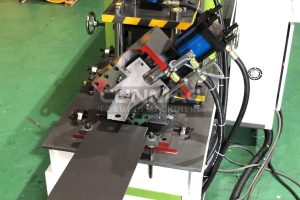

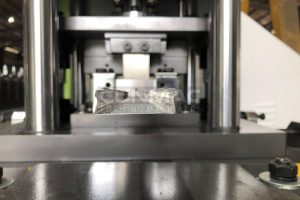

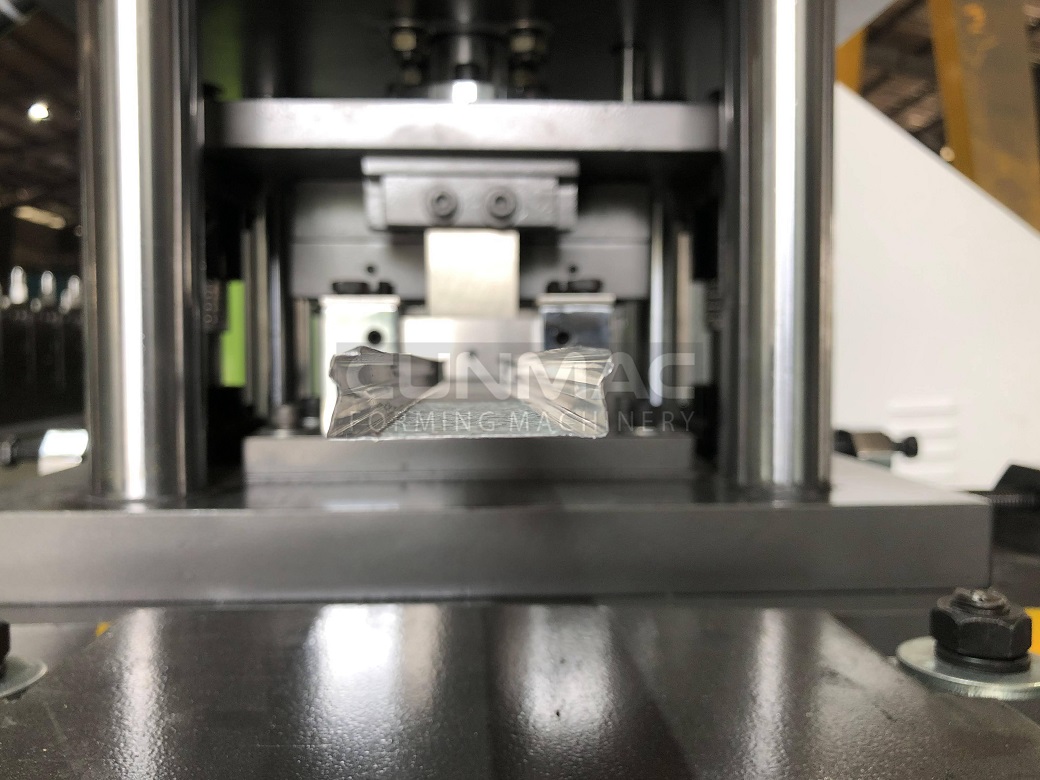

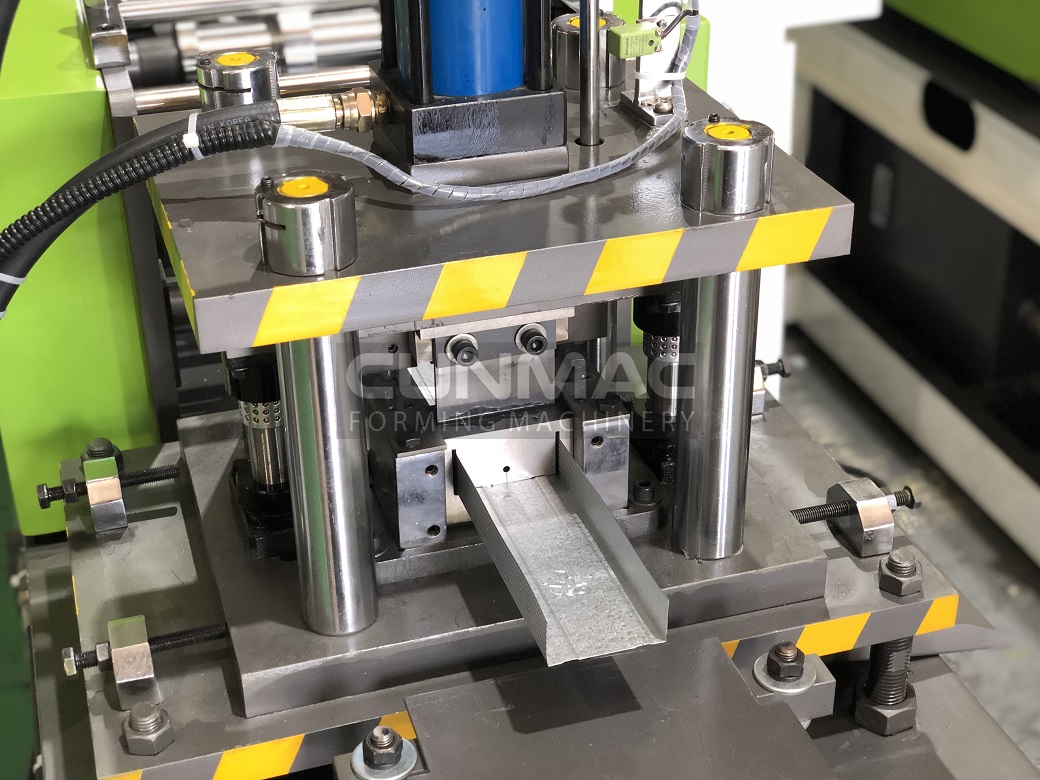

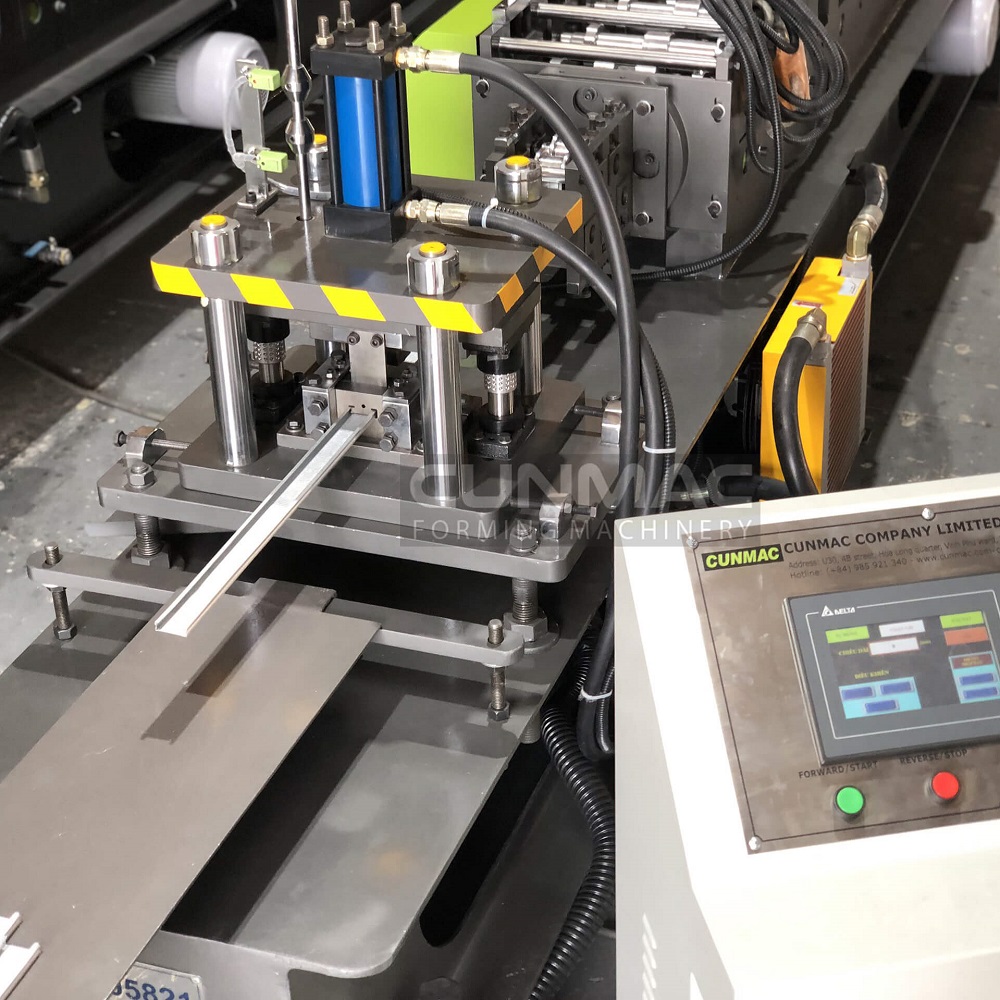

Ceiling/drywall/furring/C line roll forming machine is used to produce drywall ceiling channels (also called as C-line, Furring Channel, Drywall Frame) with stable operation by steady frame, speed up to 40m/min and customized design.

Ceiling furring drywall roll forming machine

Optional: Embossing logos on the frames is a great way that most of our customers choose to impress their customers about their brands.

Read more: Automatic C Stud & U Track Drywall Forming Machine

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

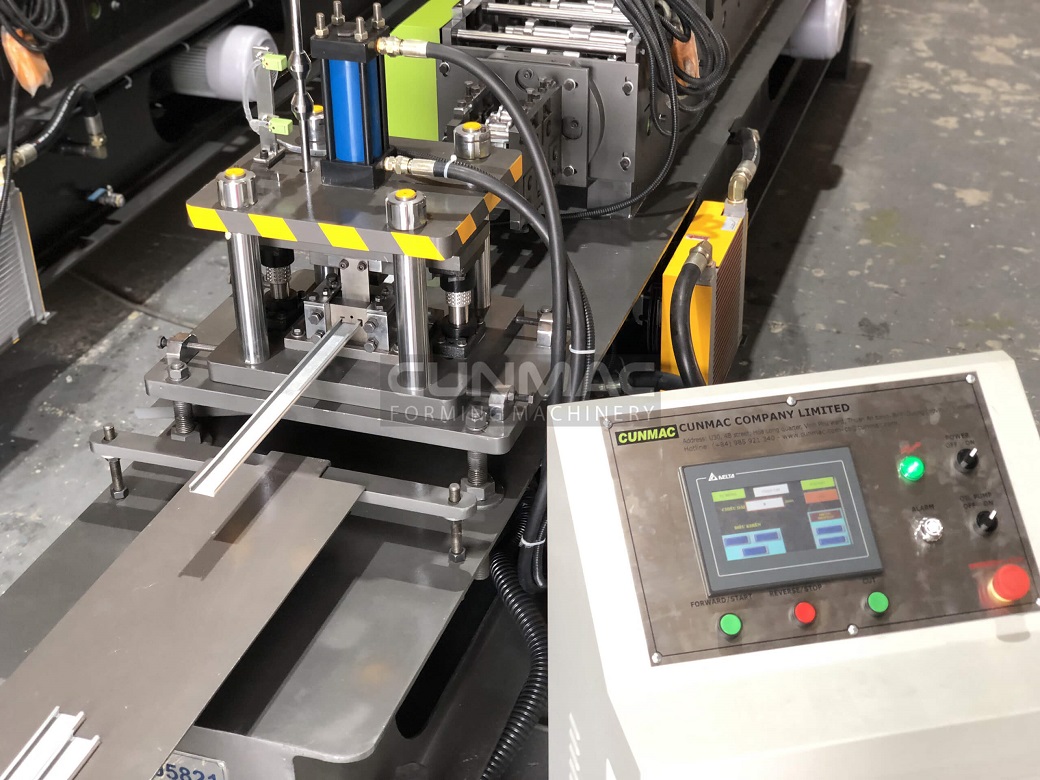

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

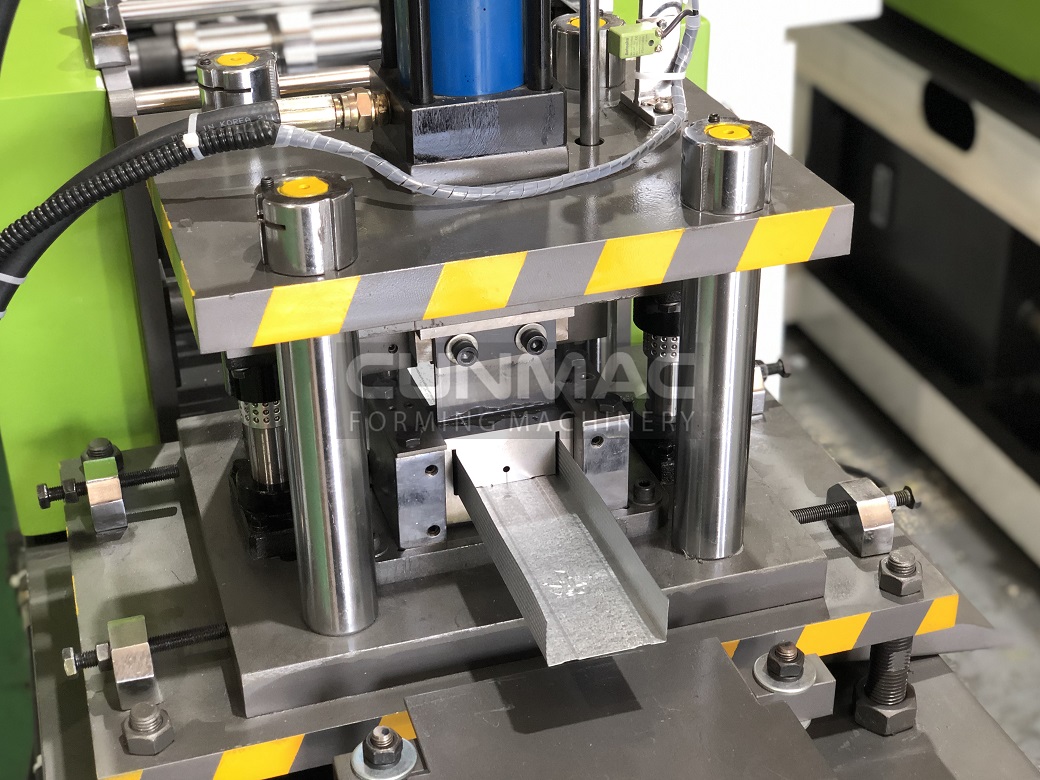

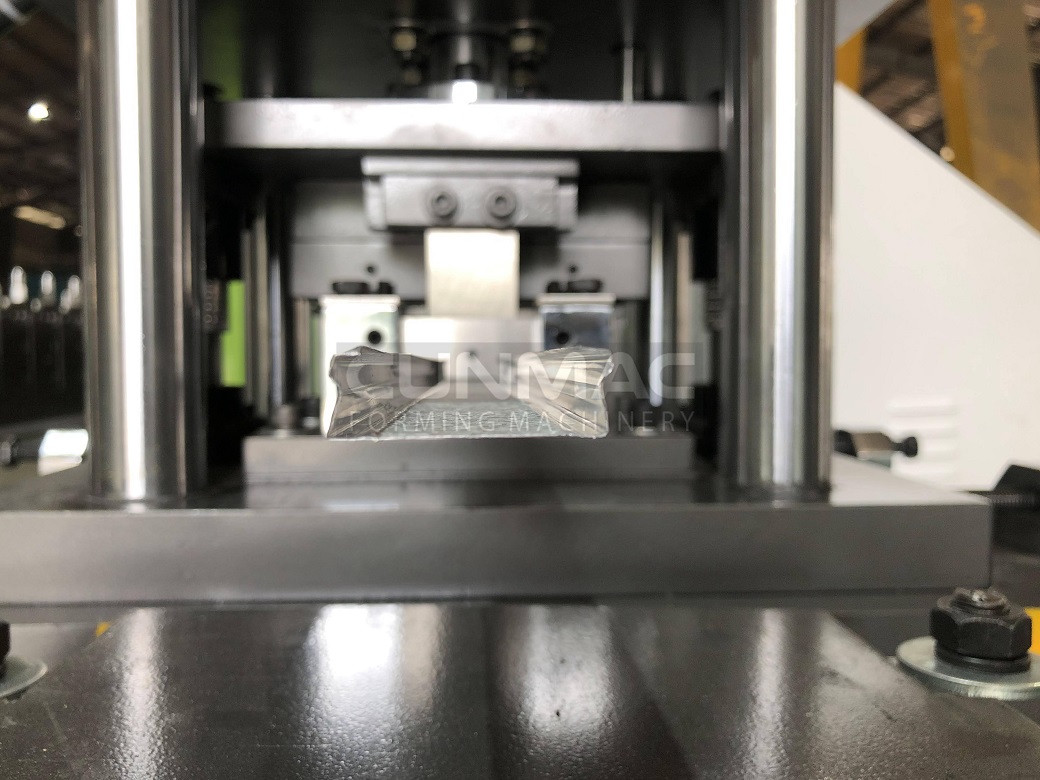

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 3.5 – 5.5kw | 5.5 – 7.5kw | 7.5 – 11kw |

| Speed | 12 – 18m/min | 20 – 24m/min | 40 – 50m/min |

| Dimension (LxWxH) | (3-5)x(1.2-1.4)x1.4m | (4-6)x(1.2-1.4)x1.4m | (4-8)x(1.2-1.4)x1.4m |

| Weight of machine | 2 – 3 tons | 3.5 – 4 tons | 2.5 – 4 tons |

| Roller station | 10 – 12 | 10 – 16 | 12 – 18 |

| Material thickness | 0.2 – 0.35mm (G300-G550) | 0.2 – 0.35mm (G300-G550) | 0.2 – 0.35mm (G300-G550) |

| Material width | 40 – 80mm | 40 – 80mm | 40 – 80mm |

| Transmission system | Hydraulic motor | Hydraulic motor | Gear motor |

| Cutting system | Hydraulic cylinder (front cutting) | Hydraulic cylinder (front cutting) | Hydraulic cylinder (front cutting) |

| Control system | Automatic with sensor | Automatic with PLC, HMI | Automatic with PLC, HMI, Inverter |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

Cunmac proudly provides Ceiling/drywall/furring/ C line roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.