Laminated PE foam roll forming machine, including standard roll forming machine and OPP machine, produces PE foam roof panels with effective heat insulation.

About polyethylene foam roofing sheet (PE foam roof panel)

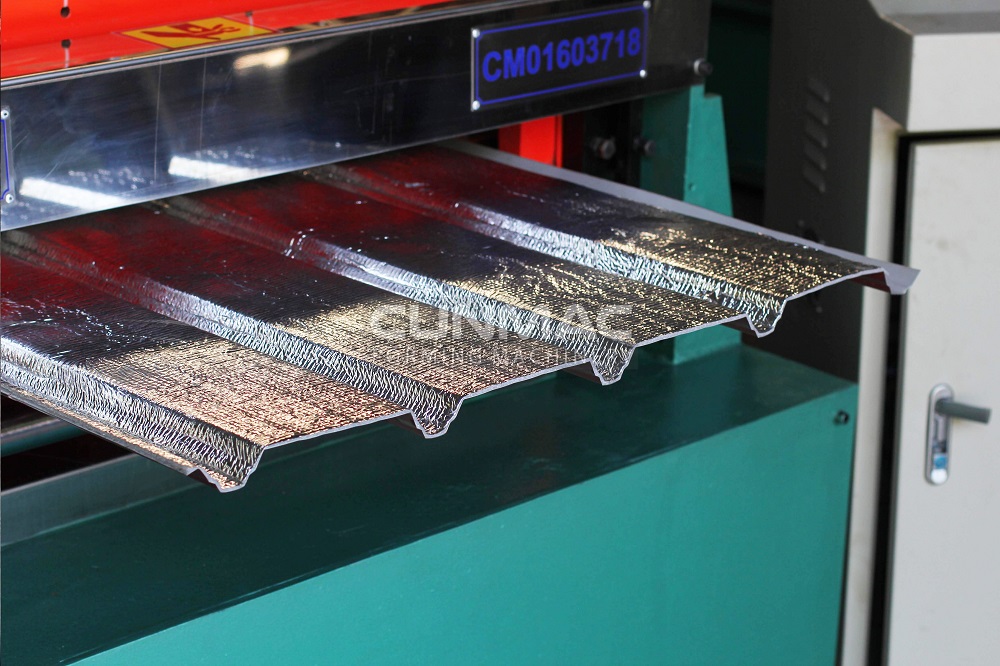

Polyethylene foam roofing sheet is a material covered with a layer of PE-OPP. That can protect the roof from moisture, absorbs shocks, reduces noise, retains heat, and is highly flexible.

PE foam panels are commonly used in different constructions: household buildings, commercial buildings or industrial buildings. Laminated PE foam sheet is an ideal and cost-effective solution for weather resistance, particularly in the face of global warming challenges today.

PE foam roofing panels

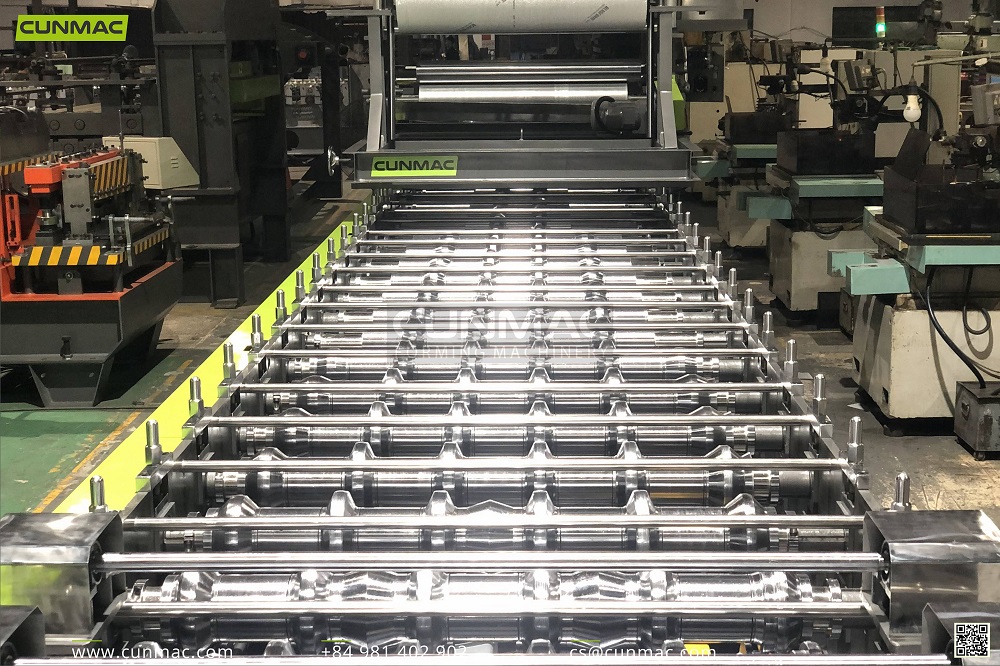

Laminated PE foam roll forming machine, including standard roll forming machine and OPP machine, produces metal PE foam roof panels by forming shapes of metal sheets then automatically glued to foamed PE insulating layer during the roll forming process. The PE foam layer fits perfectly with the roofing sheets.

Watch more: How trapezoidal roofing roll forming machine works?

Laminated PE foam roll forming machine of CUNMAC

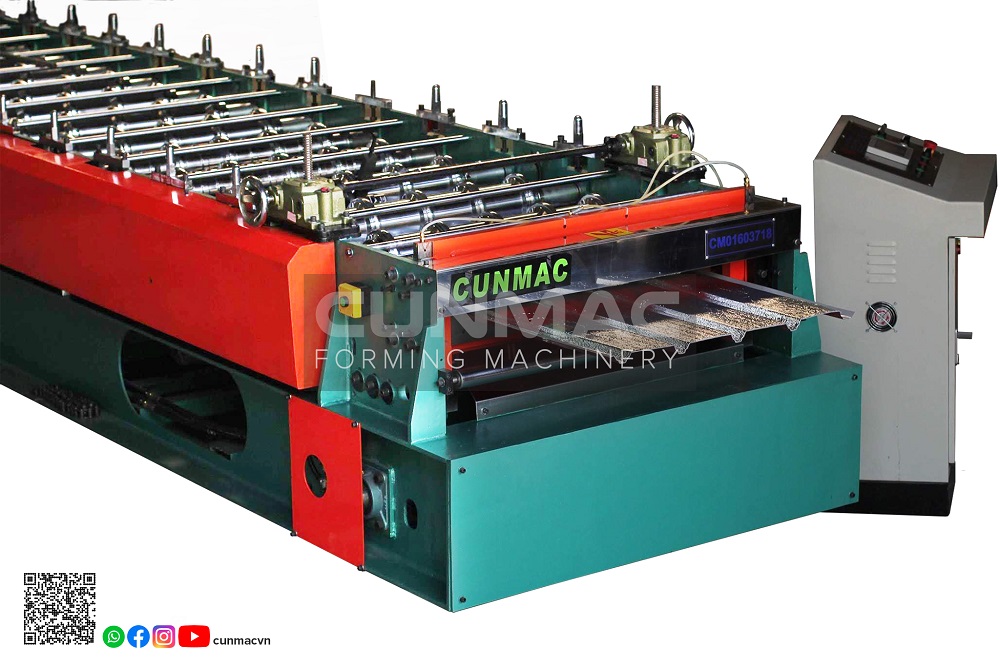

Combined standard roll forming machine and OPP machine: ideal for customers seeking to optimize factory space utilization.

The separate PE-OPP machine: perfect for customers looking to enhance existing roll forming machines with PE insulation.

CUNMAC laminated PE foam roll forming machine is fully automatic and is easy to operate with a friendly HMI panel, consists of one decoiler, sheet guiding equipment, roll forming section, PLC control system, hydraulic cutting. Their main advantages are beautifully customized designs, easy and stable operation with a strong body frame, and reasonable price.

Read more: Standard roofing roll forming machine

Machine video

SPECIFICATIONS & EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

STANDARD roofing roll forming machine with OPP machine

| SPECIFICATION | |

| Items | Details |

| Total power | 7.5kW |

| Total weight | 11 tons |

| Dimension (LxHxW) | 11×2.2×1.8m |

| Station quantity | 18 – 21 stations |

| Thickness of material | 0.15 – 0.7mm (G300-G550) |

| Thickness of PE | 5-9mm (depending on request of customer) |

| Material width | 914; 1200; 1219; 1450mm |

| Speed | Without PE: 18 – 22m/min

With PE: 12 – 16m/min |

| Tolerance of lengths | ±2mm/6000mm |

| Frame material | I beam 400mm |

| Control system | Automatic with Inverter, PLC, HMI, hydraulic |

| Cutting system | Hydraulic cylinder (rear & front cutting) |

| Transmission system | Hydraulic motor |

| Heating fan | Controlled |

| EQUIPMENT | |

| Items | Details |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | SCHNEIDER (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Bearing | KG (Taiwan) |

| CB/MCCB | FUJI (Japan) |

ABOUT CUNMAC MACHINERY

About Cunmac Machinery

Cunmac proudly provides Laminated pe foam roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.