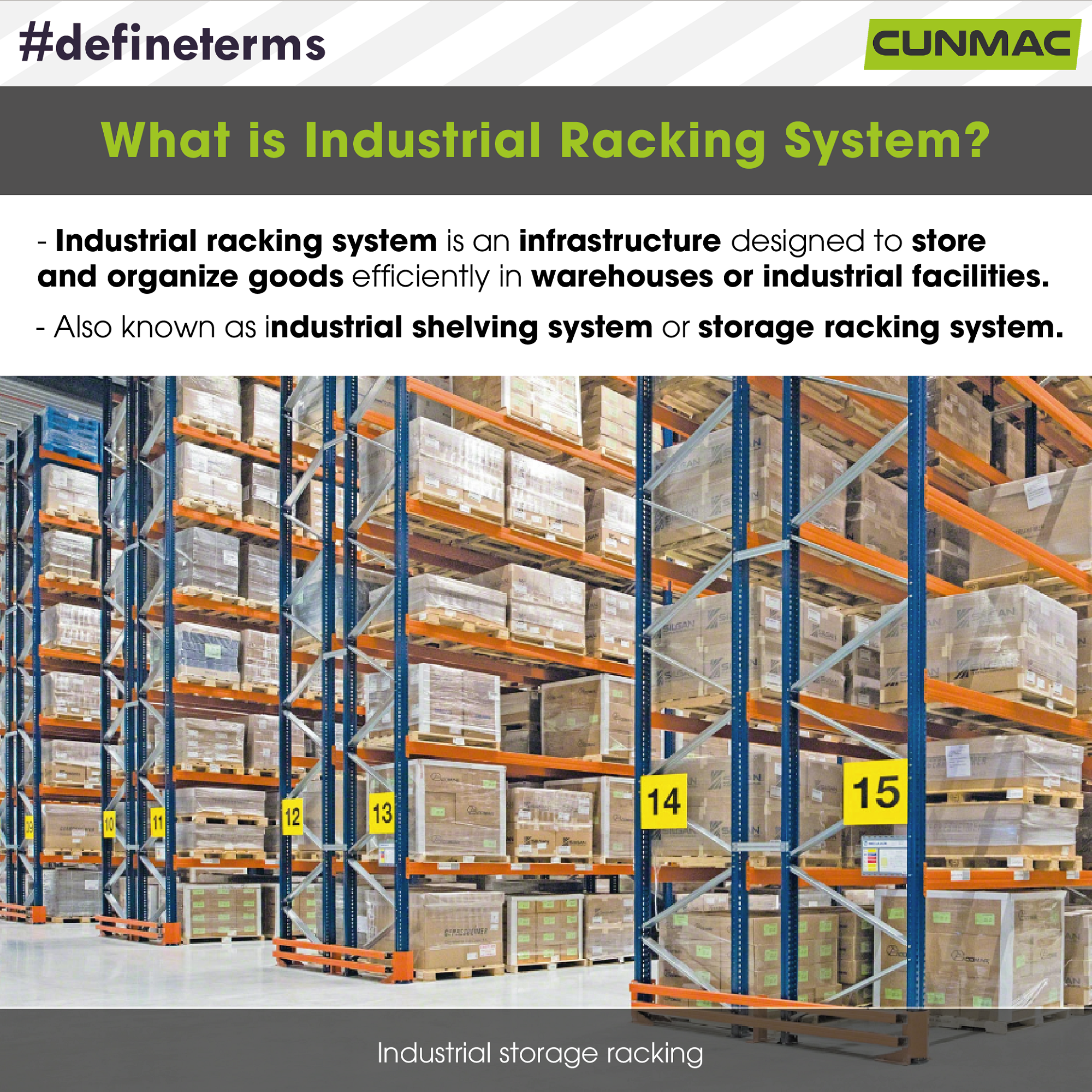

Industrial racking system, also known as industrial shelving system or storage racking system, is an infrastructure designed to store and organize goods efficiently in warehouses or industrial facilities.

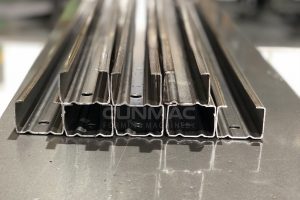

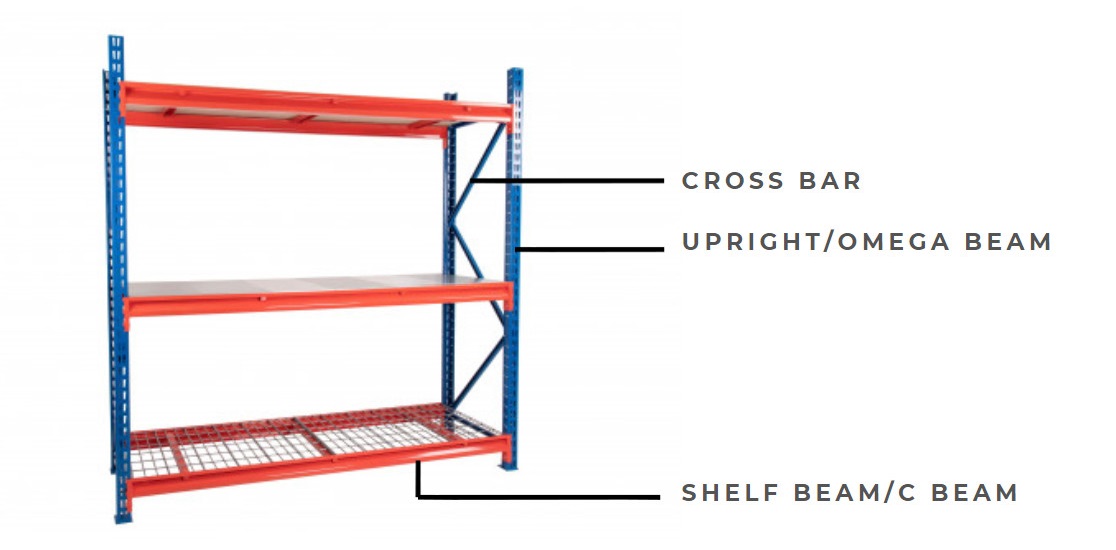

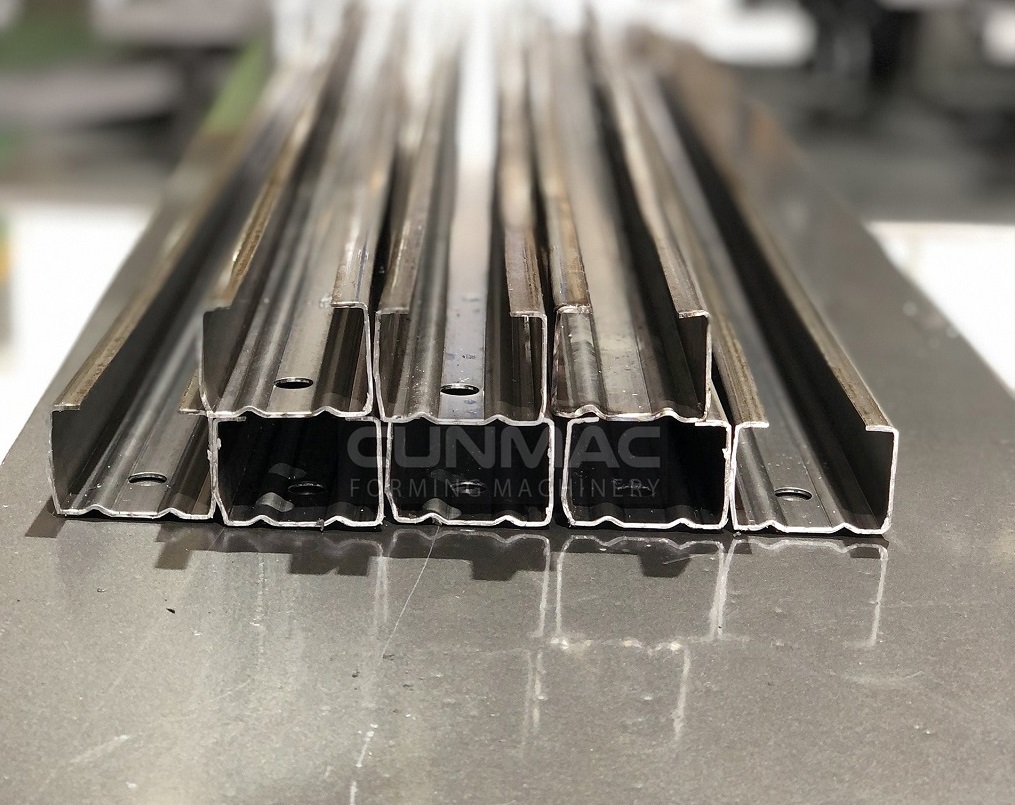

Cross bar pallet rack roll forming machine (C channel/C profile/C section rack roll forming machine) is used to produce C channels (C cross bars), in cooperation with upright/omega beams (vertical/standing beams) and C beams/Z beams (horizontal beams), which are commonly applied in industrial racking systems or warehouse racking systems.

Cross bar pallet racks (C channel/C profile/C section racks)

Thanks to its features such as versatile, durable, easy to install, and storage – efficient, pallet racking becomes a practical solution for businesses needing flexible storage options.

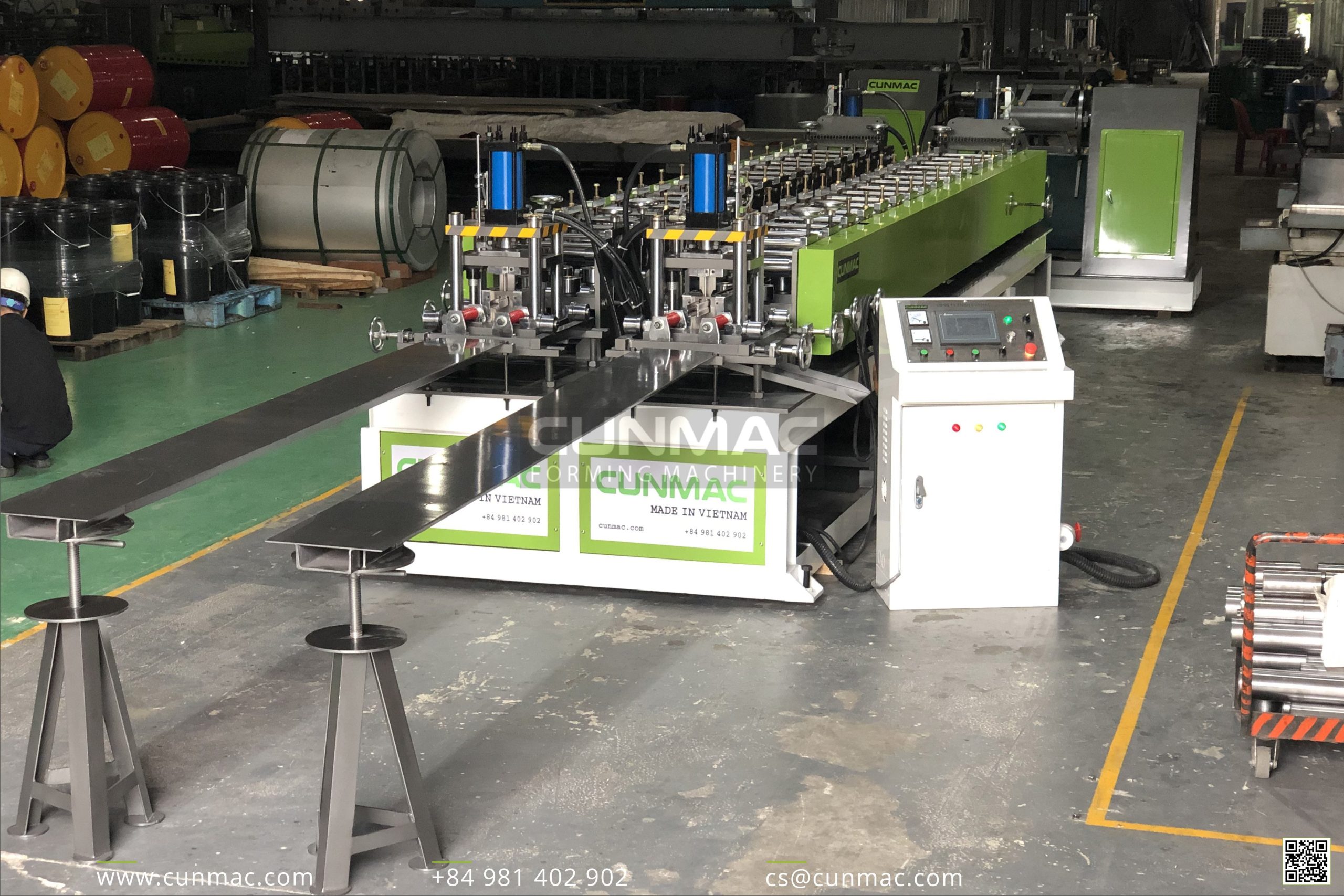

C channel/C cross bar roll forming machine of CUNMAC

Main advantages of CUNMAC’s cross bar roll forming machine:

Machine video

SPECIFICATIONS & EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

STANDARD roofing roll forming machine with OPP machine

| SPECIFICATION | |

| Items | Details |

| Total power | 11 – 18kW (3 Phase, 50Hz, 380V) |

| Speed | 16 – 18m/min |

| Dimension (LxHxW) | (8-11)x(1.2-1.6)x1.6m |

| Weight of machine | 6 – 9 tons |

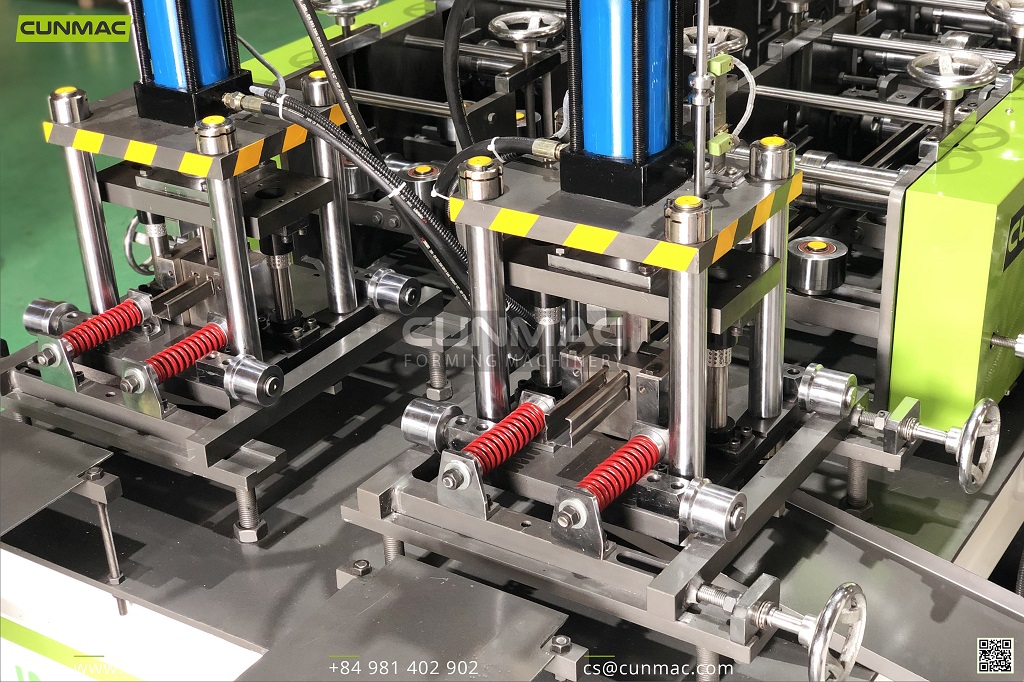

| Roller station | 14 – 20 |

| Material thickness | 1.0 – 3.0mm (G300-G550) |

| Material width | 150 – 450mm |

| Transmission system | Hydraulic motor |

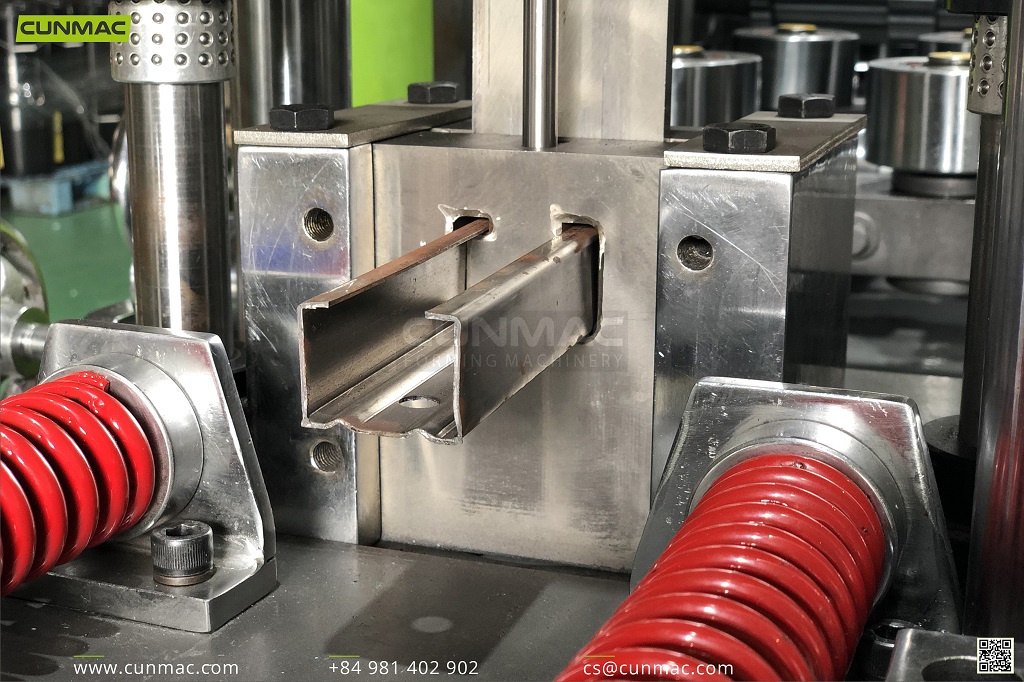

| Cutting system | Hydraulic cylinder (rear & front cutting) |

| Punching system | Hydraulic |

| Changing size | Manual with spacers |

| Control system | Automatic with inverter, PLC, HMI, hydraulic |

| EQUIPMENT | |

| Items | Details |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | SCHNEIDER (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

About Cunmac Machinery

CUNMAC proudly provides C profile storage racking roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.