What is a Kliplock roll forming machine?

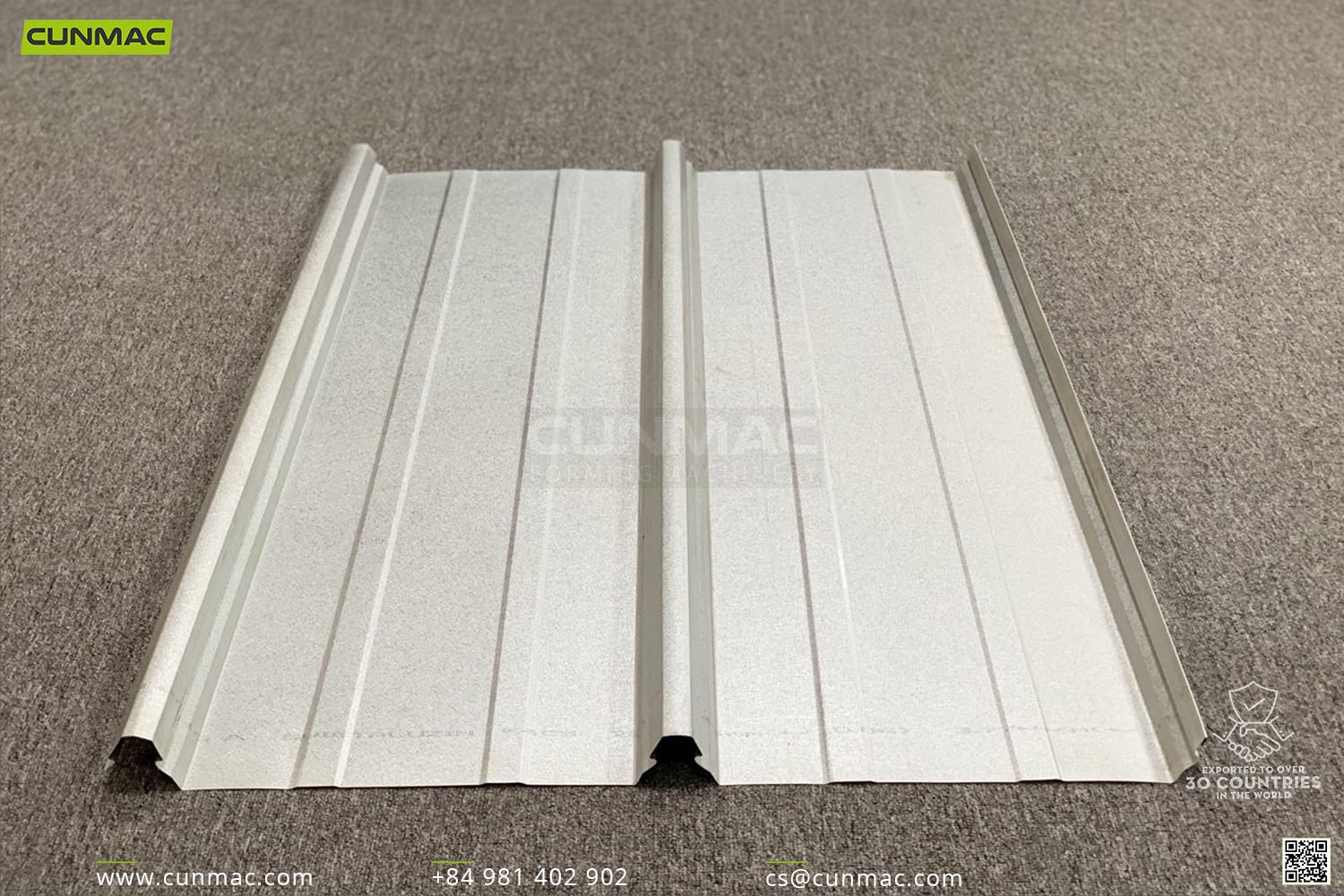

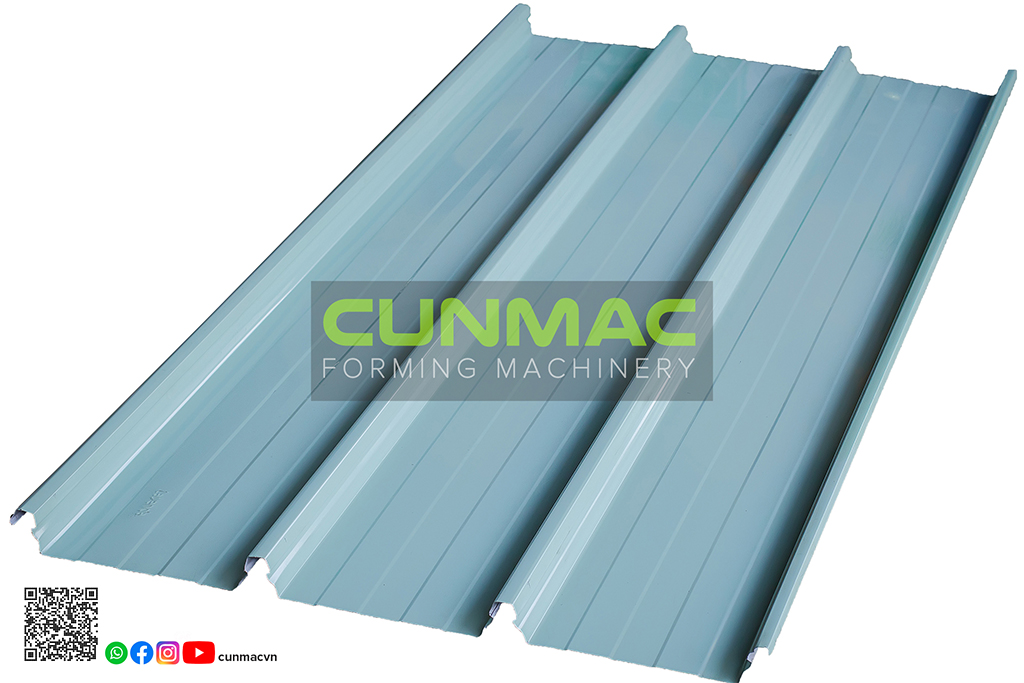

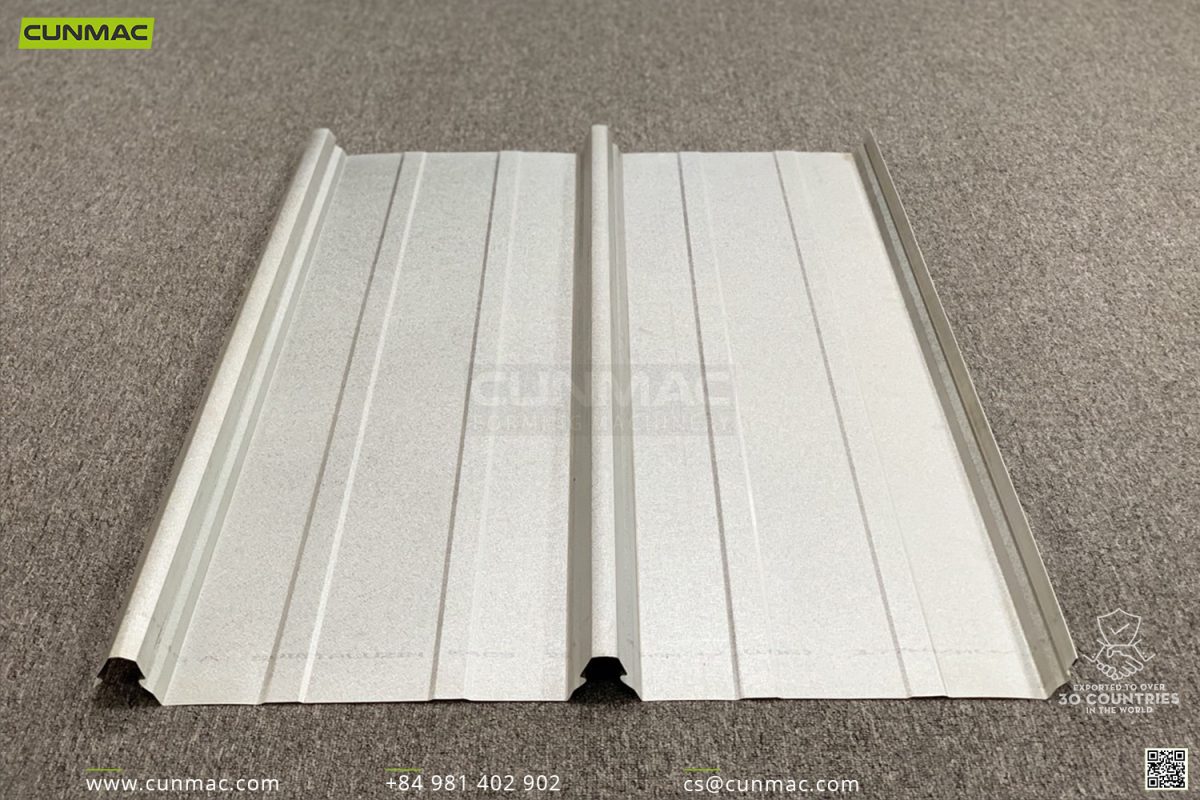

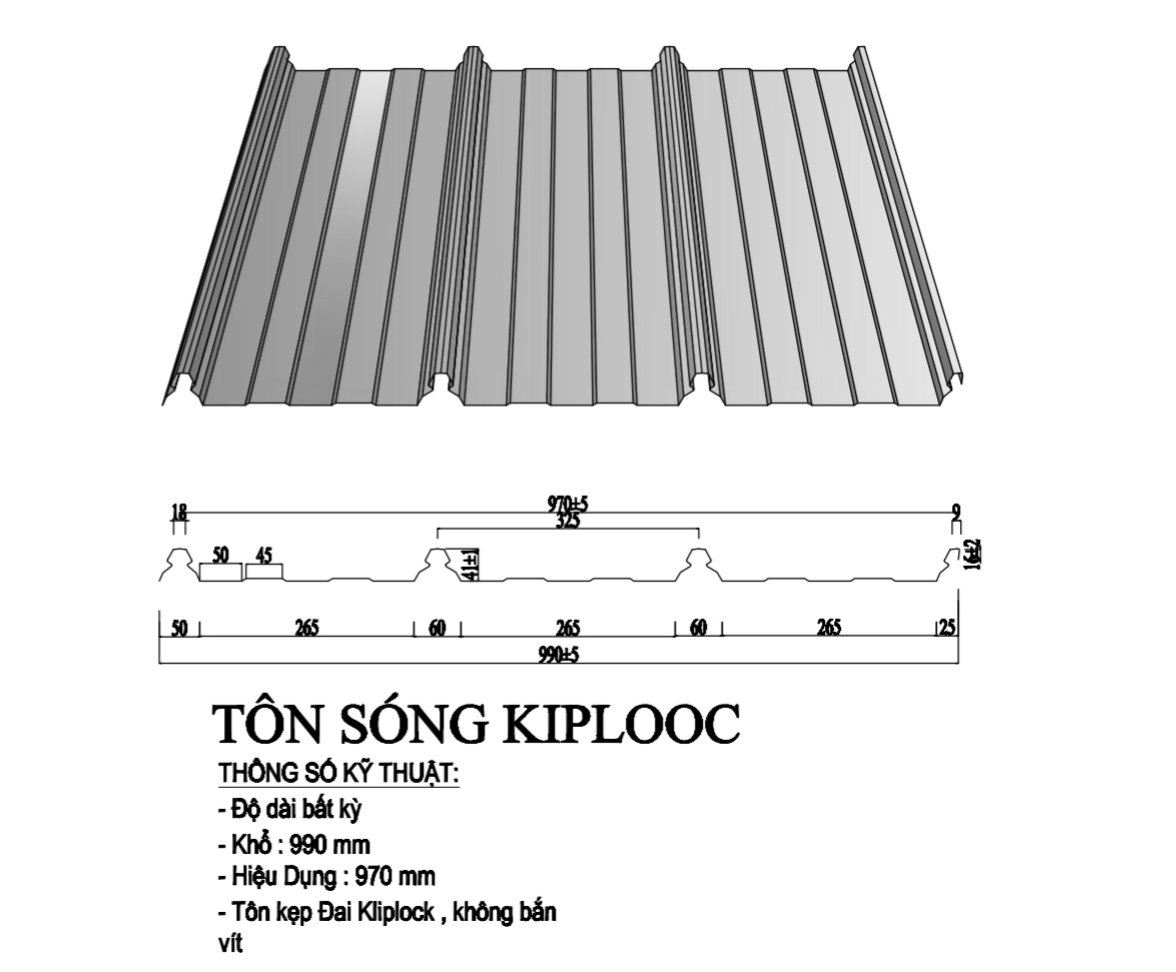

Kliplock/Klip-lok roll forming machine is also called Kliplock profile/Cliplock/Cliplock roofing sheet roll forming machine, which can produce corrugated Kliplock roof and wall cladding profile by forming metal sheets.

There are some popular types of kliplock roofing profile such as kliplok 700 and kliplok 406 with the nominal cover width 700mm and 406mm respectively.

Kliplock cladding is ideally suited to low pitched and flat roofs as well as vertical and horizontal ribbed walling. This roofing sheet is also lighter and stronger thanks to its materials of high yield steel or aluminum. Kliplock roofs are ideal for anyone looking for an easy-to-install, cost-effective and long lifespan material.

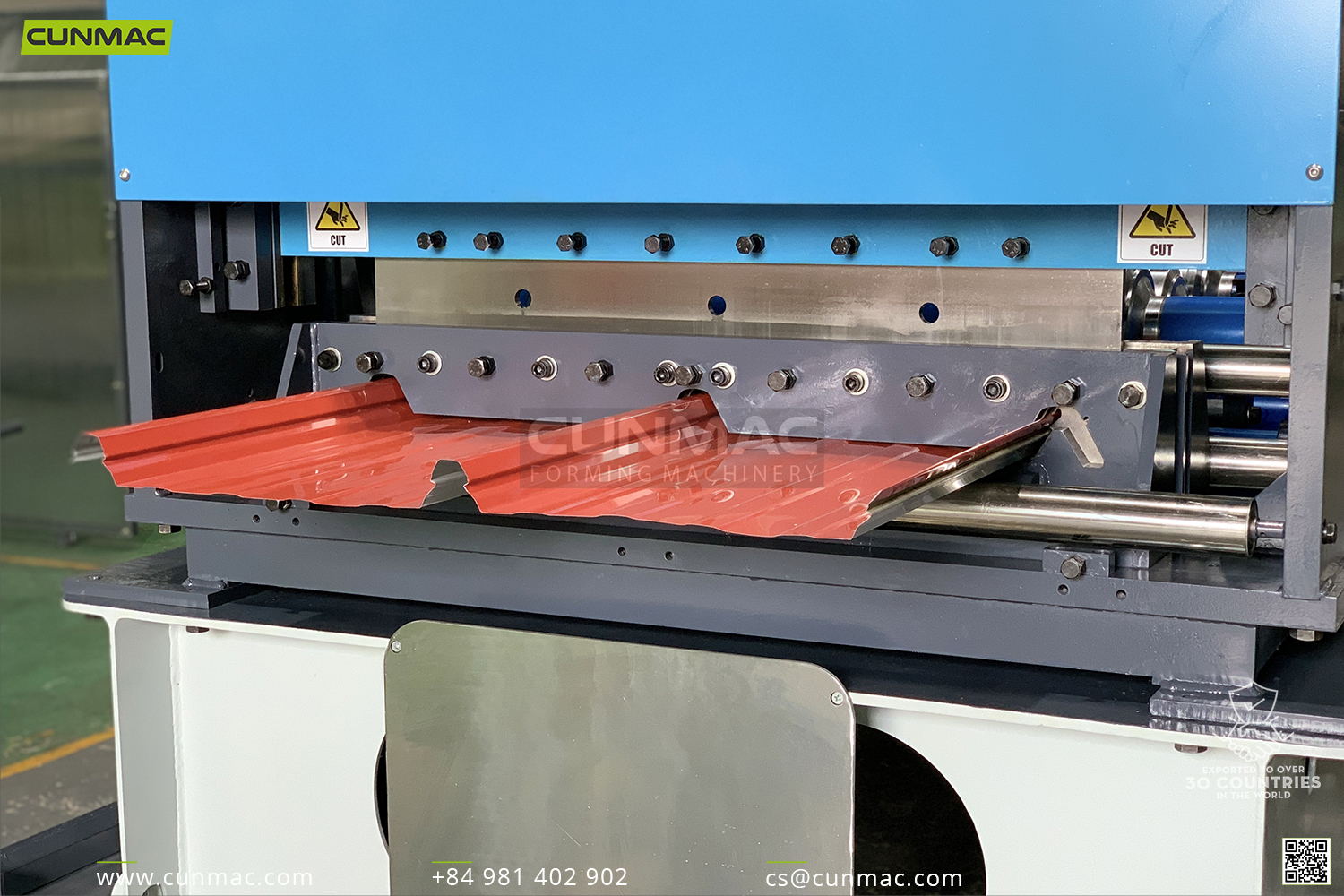

Kliplock roll forming machine is fully automatic and is easy to operate with a friendly HMI panel, consists of one decoiler, sheet guiding equipment, roll forming section, PLC control system, hydraulic cutting. Their main advantages are beautifully customized designs, easy and stable operation with a strong body frame, and reasonable price.

Kliplock roll forming machine

Machine video

SPECIFICATIONS & EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

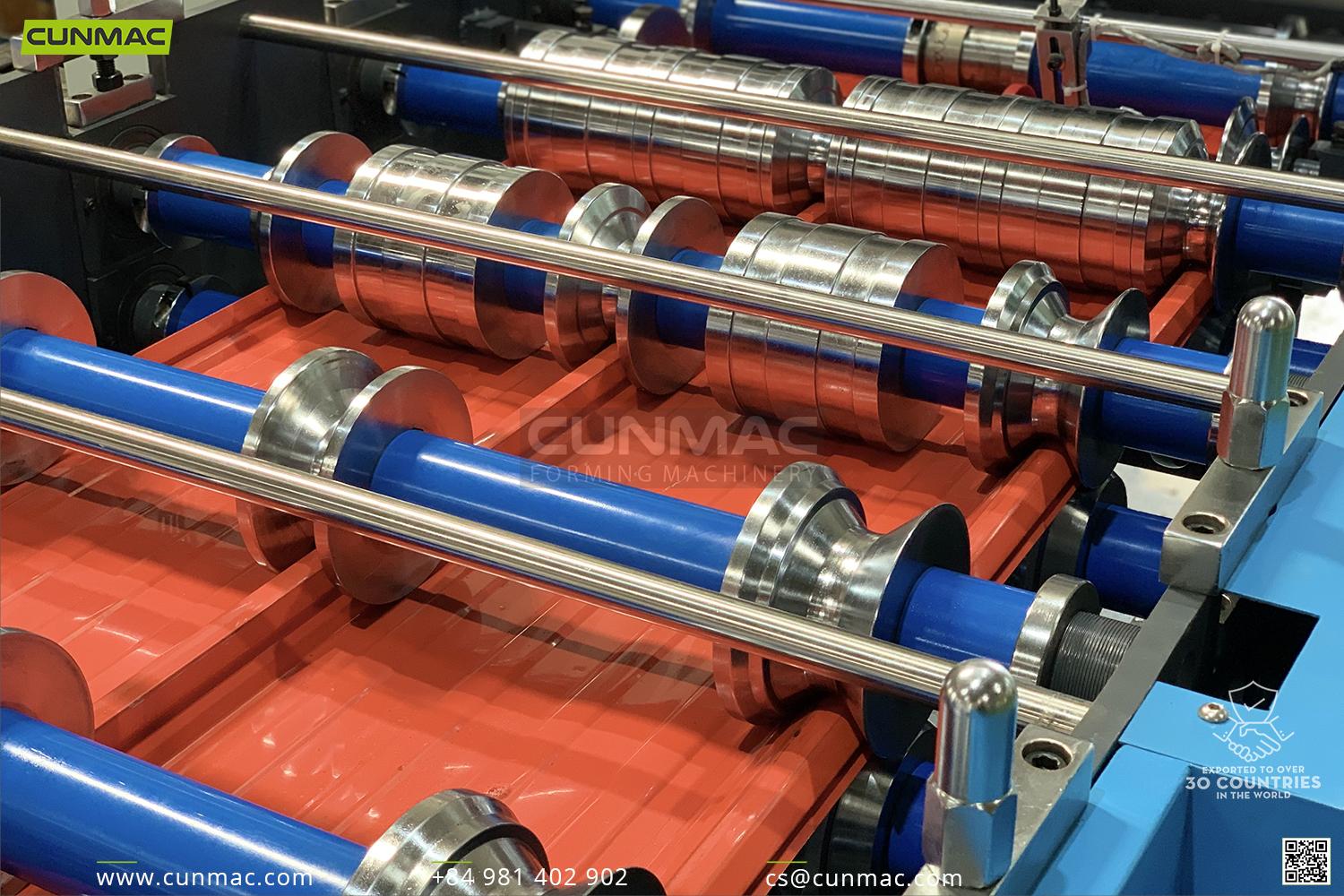

- Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

CUNMAC mobile Kliplock roll forming for onsite manufacturing

Due to the typical point of Kliplock roll forming machine that it is often carried out to construction sites, Kliplock machine is required to be stronger and more solid than others.

| SPECIFICATION | |

| Items | Details |

| Total power | 11kW (3 phase, 50hz, 380v) |

| Speed | 18 – 22m/min |

| Dimension (LxWxH) | ~14.0m x 1.6m x 1.5m |

| Weight of machine | ~13 tons |

| Roller station | 30 – 33 pairs |

| Material thickness | 0.2 – 0.7mmBMT, G400 – G550 (galvanize, zincalume, color coating steel) |

| Material width | 610mm, 914mm |

| Transmission system | Hydraulic |

| Cutting system | Hydraulic (pre-cutting system, profile cutting system) |

| Control system | Automatic with inverter, PLC, HMI, hydraulic |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

About Cunmac Machinery

Cunmac proudly provides Klip lock roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.