A reliable roof requires a combination of roof trusses and roof battens. Let’s check the difference between them and their role in the roofing system now!

1. What is roof truss and roof batten?

A truss is a structure using straight materials to form the roof in a triangle shape. The trusses combine and connect to make up the roof structure. Trusses, also known as rafters, have a standard thickness of 0.6 – 1.0mm.

Roof trusses

Roof battens, also known as roofing lath or top hat, are used to provide a fixing point for roofing materials in tiled roofs. They may not always be used in a roofing system, and typically have a standard thickness of 0.4 – 0.6 mm.

Roof battens

Generally, truss and batten are the perfect couple for a great roof structure, especially lightweight structure. You can find them supporting the roofs of auditoriums, cinema halls, stadiums, railways, stations, airports and others.

2. How to produce truss and batten?

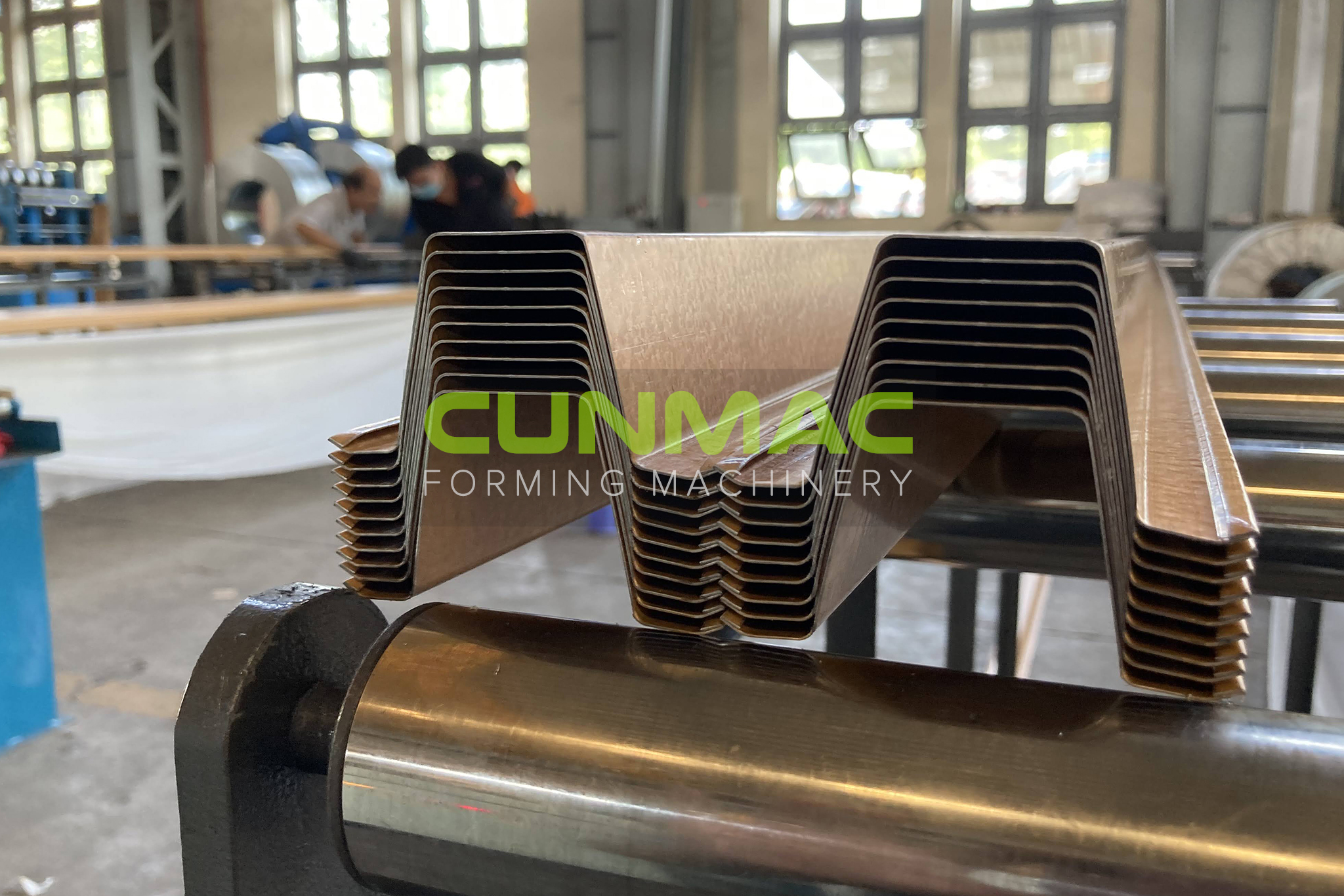

We use truss roll forming machine (for lightweight structure) to produce truss and batten by feeding a flat strip of material through a series of rollers and other components that gradually shape the material into the desired profile.

The machine is set up to match the specific size and shape, and the finished product is cut and inspected for quality.

Producing truss and batten at CUNMAC factory

Through this post, CUNMAC team has given you the basic things you should know about roof truss and roof batten. Don’t forget to follow the next issue of our series #defineterms to update more useful information.

This series belongs to CUNMAC Vietnam.

CUNMAC Vietnam – Roll Forming Machine Manufacturer has 15 years experience to ensure machine quality and customer satisfaction all over the world.

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.