CUNMAC has a successful shipment of 2 sets of combined C profile/C shaped/C section roll forming machine to our valued customer in Angola. Follow this article for details!

CUNMAC Vietnam is delighted to announce the successful shipment and delivery of the product – Combined C profile roll forming machine – to our valued customer in Angola.

This achievement marks another highlight in the company’s commitment to delivering high-quality machinery solutions to customers worldwide.

Delivering full set of machines to our customer

The combined C profile/C shaped/C section roll forming machine, designed and manufactured by CUNMAC, is a machine that combines 2 separate machines together. It is usually used to produce sturdy and precise C-shaped trusses used in various applications, especially for lightweight constructions. Main advantage of this combined 2 in1 roll forming machine is cost-saving, which means that choosing this machine can save up to 15-20% machine investing (input) cost compared to two separate machines.

In addition to the C-shaped, there are some other channels that can be combined such as: batten/top hat/hat channel, C truss/C section/C shape, C ceiling/furring, C stud, U track, V shape… with material thickness is often below 1.0mm.

Read more: Batten roll forming machine

Combined C profile machine incorporates advanced features and precise engineering, offering excellent reliability, durability, and productivity:

- Available equipped with 2 sets of semi-auto decoiler 2 tons and 2 sets of manual run-out table 4m for each combined machine

- Speed of 30m/min (special option up to 50 – 60m/min)

- Quantity of roller stations: 10 – 14 pairs, weight 4.5 tons with a strong body frame

- Width of coil and thickness of material follow customer requirements

- With a control system managed by a PLC and touchscreen interface, high quality cutting system, optional with punching system

- Quality materials for rollers and blades from SKD11 Japan, S45C Taiwan, components from Japan (Mitsubishi, Hitachi, Omron…), Germany (Siemens), Taiwan (Yuken, Delta)

2 sets of combined C profile/C shaped/C section roll forming machine

Read more: C profile/C section roll forming machine

Combined 2in1 machine with 2 shapes of channels (V shaped & C shaped)

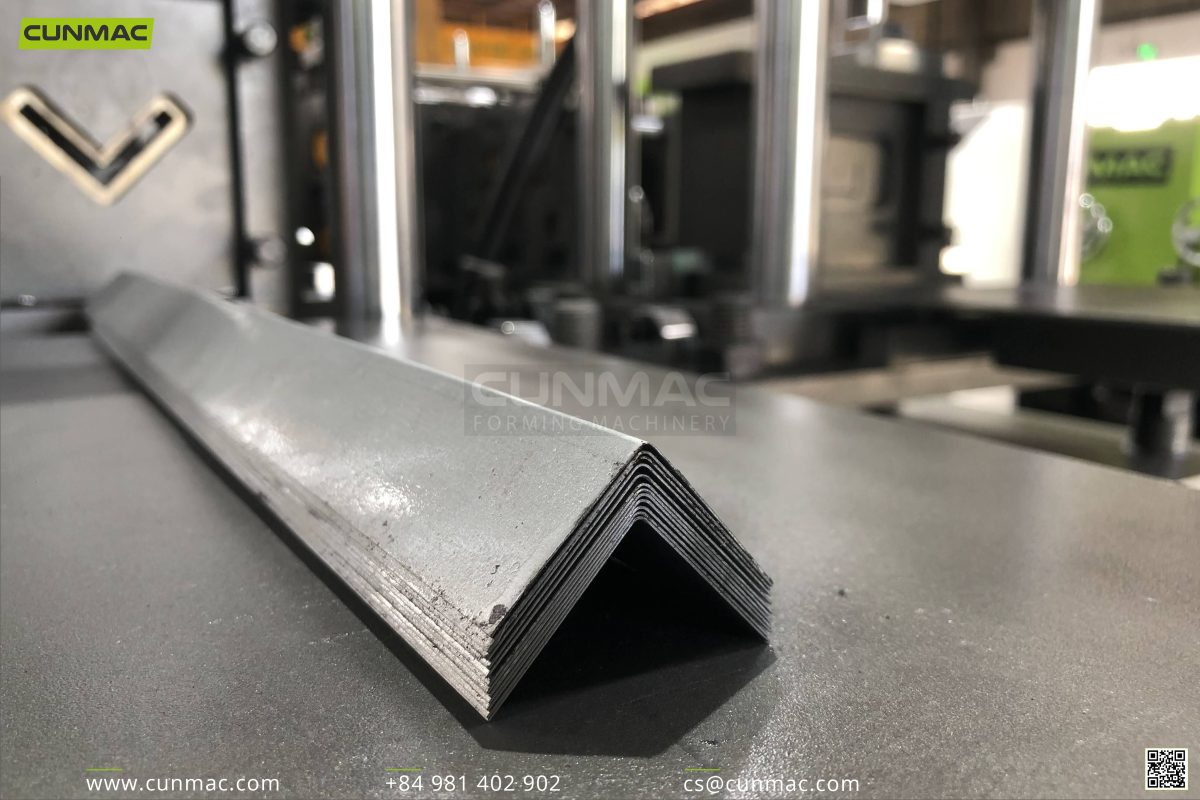

Let’s take a look at some finished samples of these machines:

Finished testing samples: V shape and C shape channels

Read more: V angle/V shape roll forming machine

Semi-auto decoilers available equipped:

Read more: Auto decoiler/uncoiler

This achievement marks another highlight in our company’s commitment to delivering high-quality machinery solutions to customers worldwide.

We are pleased to share an exciting video documenting the successful delivery journey of our combined C profile roll forming machines. From careful packaging to secure transportation, witness the dedication and expertise of our logistics team as they ensure the safe arrival of the products. Join us on this behind-the-scenes journey:

We, a roll forming machine manufacturer, specialize in custom designing and manufacturing a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

Our products are delivered across many markets: America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia and Vietnam.

If you are looking for a roll forming machinery that guarantees superior performance, reliability, and customer satisfaction, look no further than CUNMAC.

CUNMAC is committed to delivering beyond expectations, and the successful delivery of the Combined C profile roll forming machine is a testament to our resolute dedication to our customers worldwide.

Contact our expert team today to discuss your specific requirements and experience excellence in roll forming machinery firsthand.

ABOUT CUNMAC MACHINERY

CUNMAC Co., Ltd is a leading manufacturer of cold roll forming solutions that addresses the demands of the modern construction industry. With over 15 years of experience, we have built a reputation for delivering high-quality and innovative roll forming solutions to customers across the globe.

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.

Hotline: +84 981 402 902

Mail: cs@cunmac.com

Please contact our consultants today, we would be really happy to assist you.