Roll Forming Machine Price is based on the requirements of the profiles of the steel product you want to produce. Before making any decisions to start a new brand or expand your business, consider carefully the below factors to make the best choice out of thousands of options in the market.

Understand your need

Here crucial Questions that manufacturers usually ask customers before offering any quotation for roll forming machines.

– Profiles or photos of sample

– Material (coil width, thickness, tension)

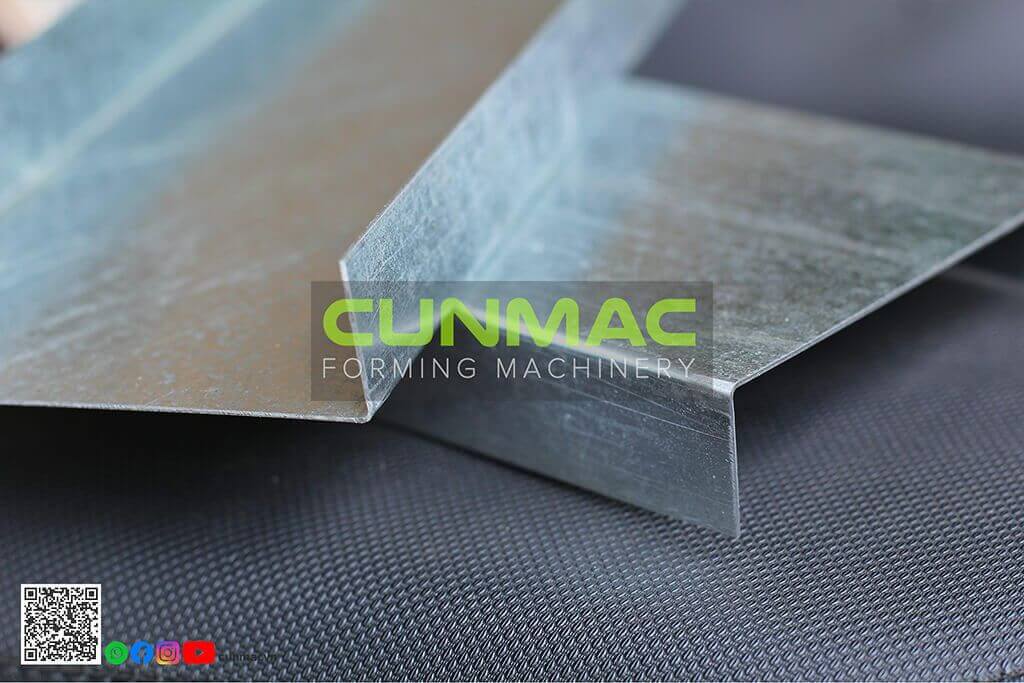

Profile designs and Material Thickness

Now there are many steel profiles that can be roll formed by roll forming machines. The max wider product is up to 1450mm width, while the min-width is below 10mm. The thickness can be up to 4.0mm, and also can be lower to 0.12mm. The steel profiles can be used for Roofing Systems, downspout Systems, Pallet Racking Systems, etc.

It does not mean that the machine for the wider profile is expensive than a narrow profile. And of course same as thickness. The profile drawings and thickness will influence the forming steps of the roll forming mill and roll forming machine price

Motor and Electric Components

Motor and Electric Components decide the reliable performance and lifespan of a machine.

All parts of Cunmac products fabricated from alloy steel by CNC precision machines. Electrical and hydraulic components derive from reputable brands such as Siemens, Schneider, OMRON, Hitachi, Yuken, etc

.

Warranty and After-Sales Service

When you invest in a machine or solution from you are assured that the manufacturers are committed to stable production with exceptional after-sales services

At Cunmac, your success is our success, and therefore we always strive for a long and good partnership that is based on good quality, availability, and service. Partnership for Success!

We design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction, and manufacturing industries.

Our goal is to provide flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experiences.

Your success is our success!

Very interesting and useful article, thank you!