Go with CUNMAC – In this article, we shall enjoy a cup of tea and have a brief talk about roof truss and roof battens in constructions. Let’s go!

1. Understanding the structure of a roof

Every single roof starts with a truss system. The truss system is the skeleton of the roof and most homes have a wooden or metal truss system. The role of this system is as a deck of the roof.

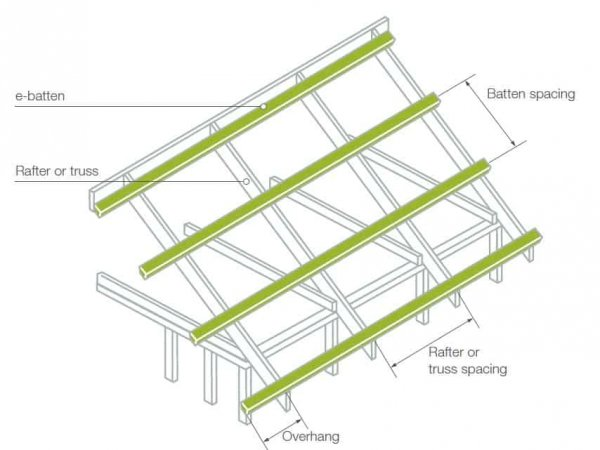

The deck is the platform that other roofing material is attached to. The deck is covered with a layer of protective materials to which the shingles, tiles or metal sheets are directly attached to or through the battens of tiled roof (also known as “lightweight purlins” – in contradiction to purlins used for metal roof) in combination with the trusses (rafters).

Truss and batten are the perfect couple for a great roof structure,especially lightweight structure. You can find them supporting the roofs of auditoriums, cinema halls, stadiums, railways, stations, airports and others. Now, let’s get right down to know more details of roof truss and batten.

Truss and batten – a perfect couple for roof structure

2. Definition of roof truss and roof batten

In structural engineering, the name “truss” describes a triangular design. A truss is a structure that uses straight materials (usually) to form the roof in a triangle shape. When the trusses combine and connect, they make up the roof structure. Trusses are also named rafters.

Roof batten or battening, also called roofing lath or top hat, are often used for tiled roofs to provide the fixing point for roofing materials such as shingles or tiles. Battens are not always used in a roofing system.

Roof with trusses and battens

3. Types of roof truss system

Since there are different types and variations of roof trusses, let’s find out the most popular ones and what distinct features they have.

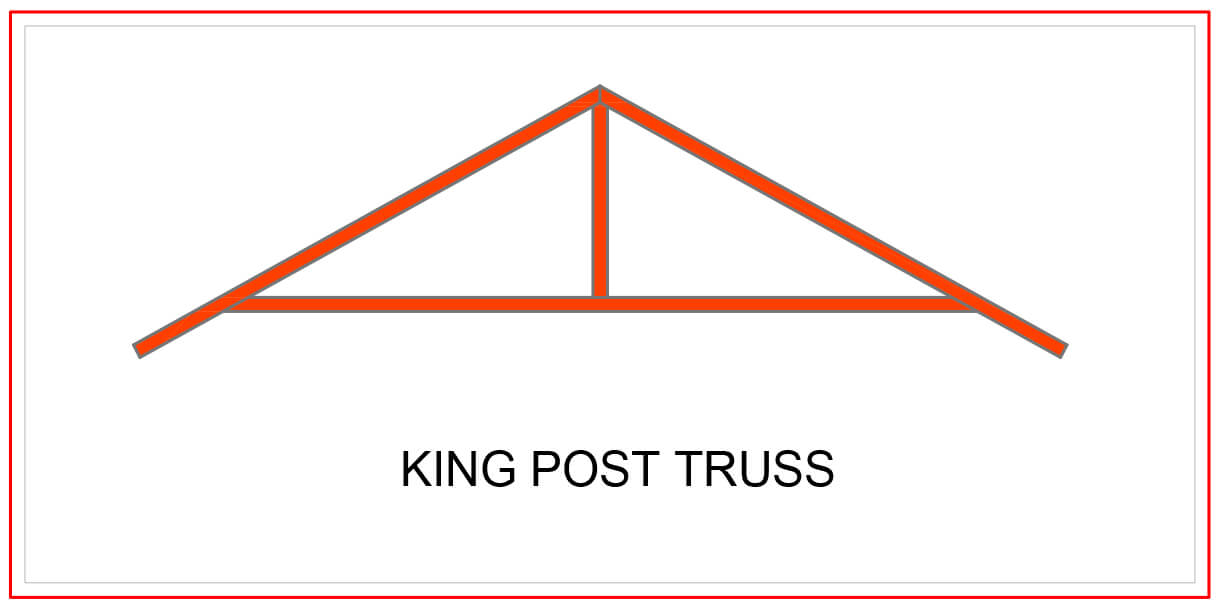

- King post truss:Central vertical post used in architecture, working in tension to support a beam below from a truss apex, perfect for multiple types of houses, especially the smaller ones.

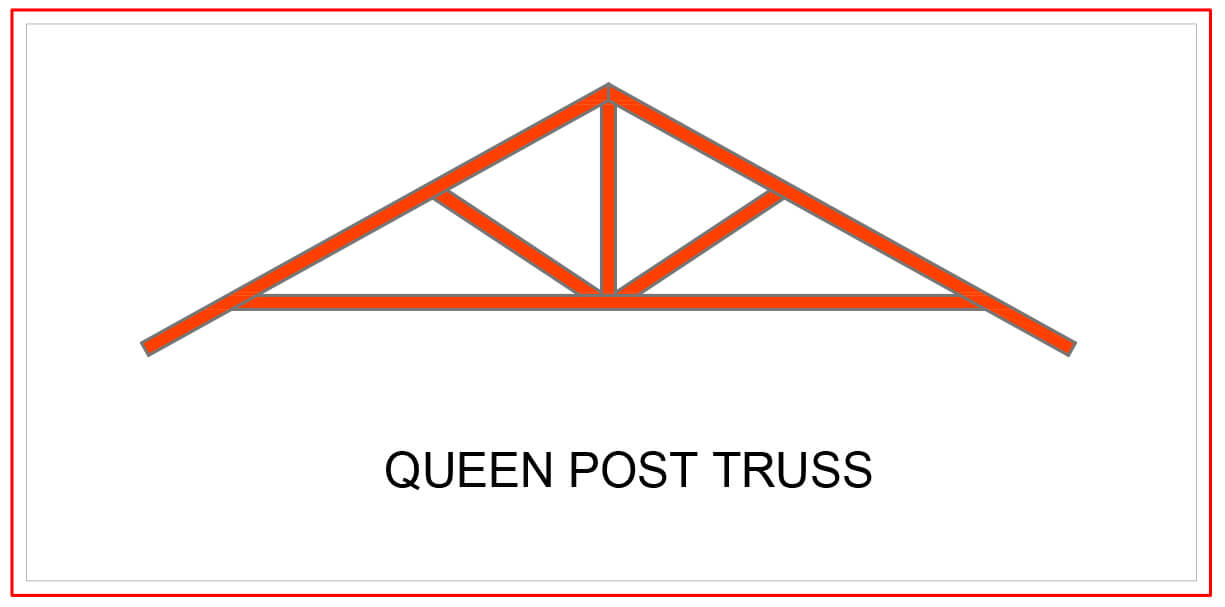

- Queen post truss:A very reliable, simple and versatile type of roof truss where you can use at any given time, perfect for a wide range of establishments.

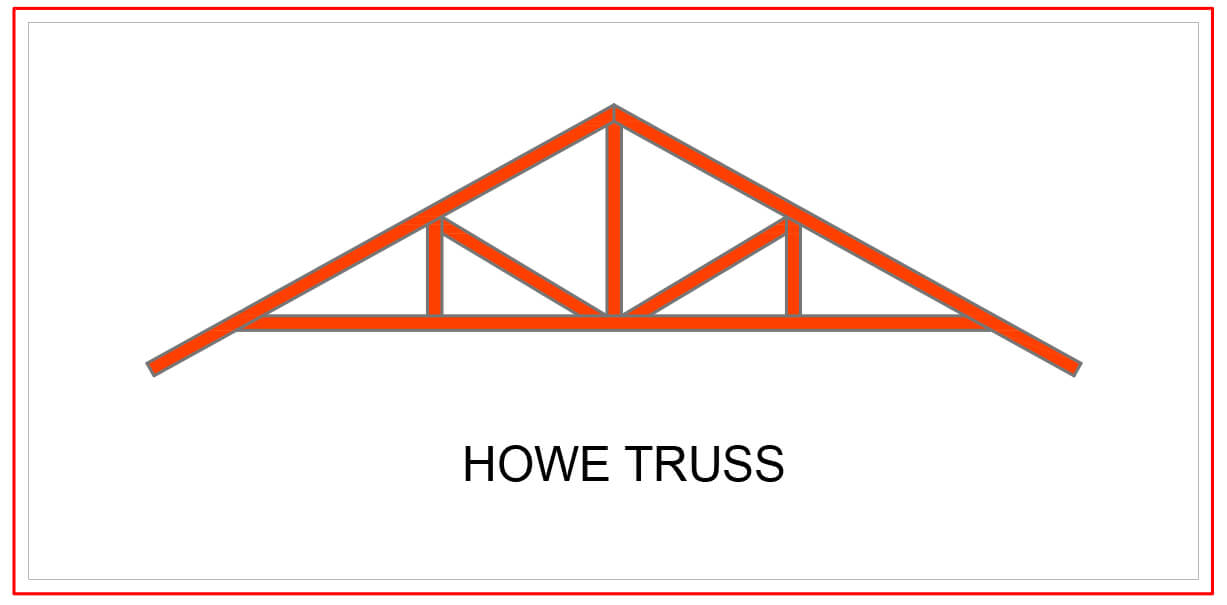

- Howe truss:A kind of truss having upper and lower members, a combination of steel and wood or both. One thing that makes this truss extraordinary is that it has a very wide span.

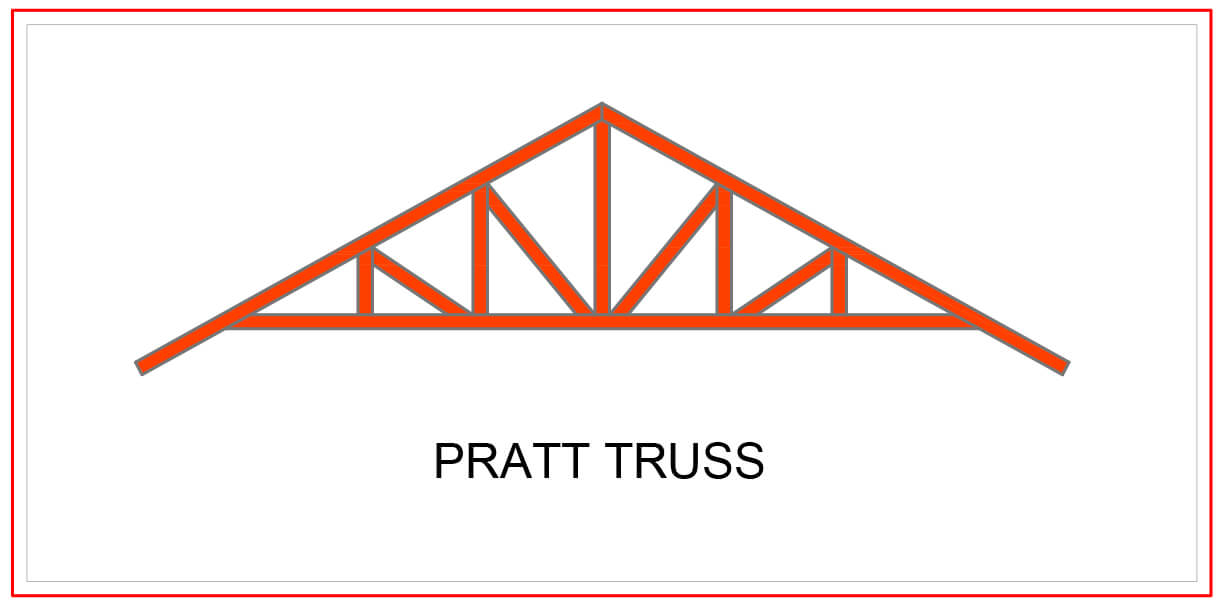

- Pratt truss:The most popular steel truss since it is very economical. It includes vertical and diagonal members that slope down towards the center (opposite of Howe Truss).

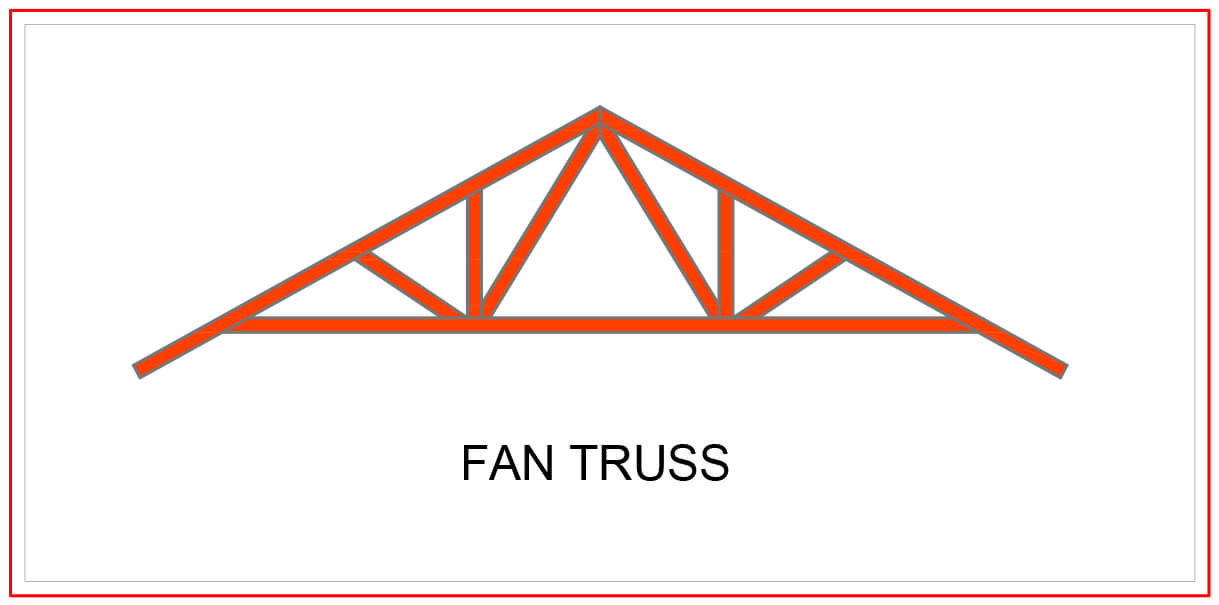

- Fan truss:A simple design made out of steel. Most projects with a larger span uses this kind of truss.

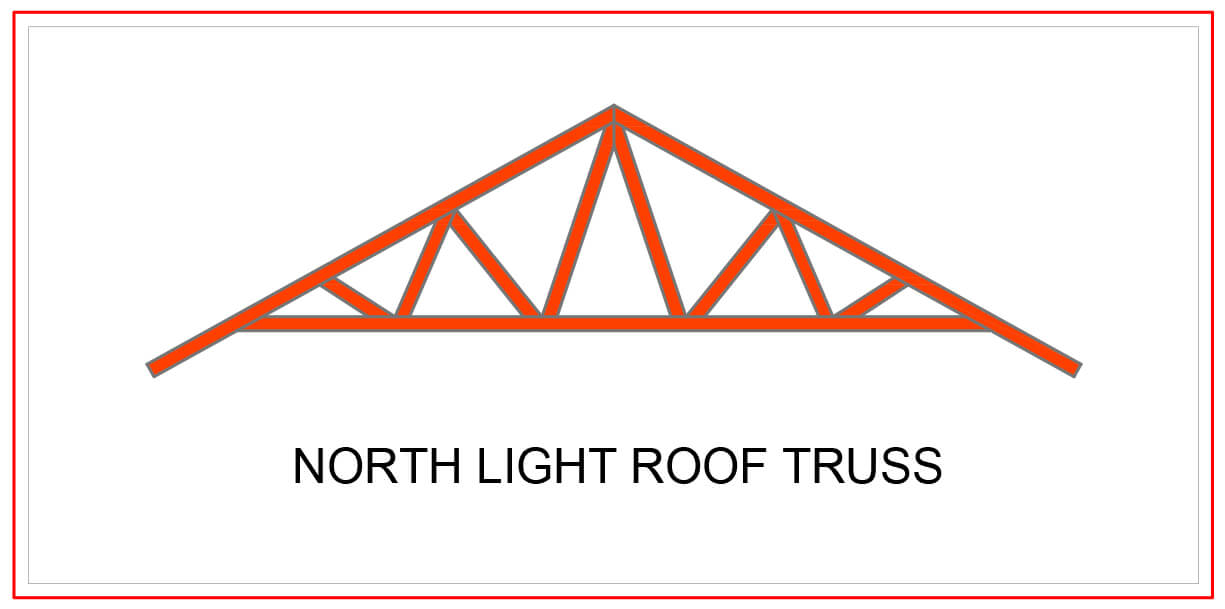

- North light truss:The oldest, and most economical kind of truss. These are found in industrial buildings, drawing rooms and large spaces.

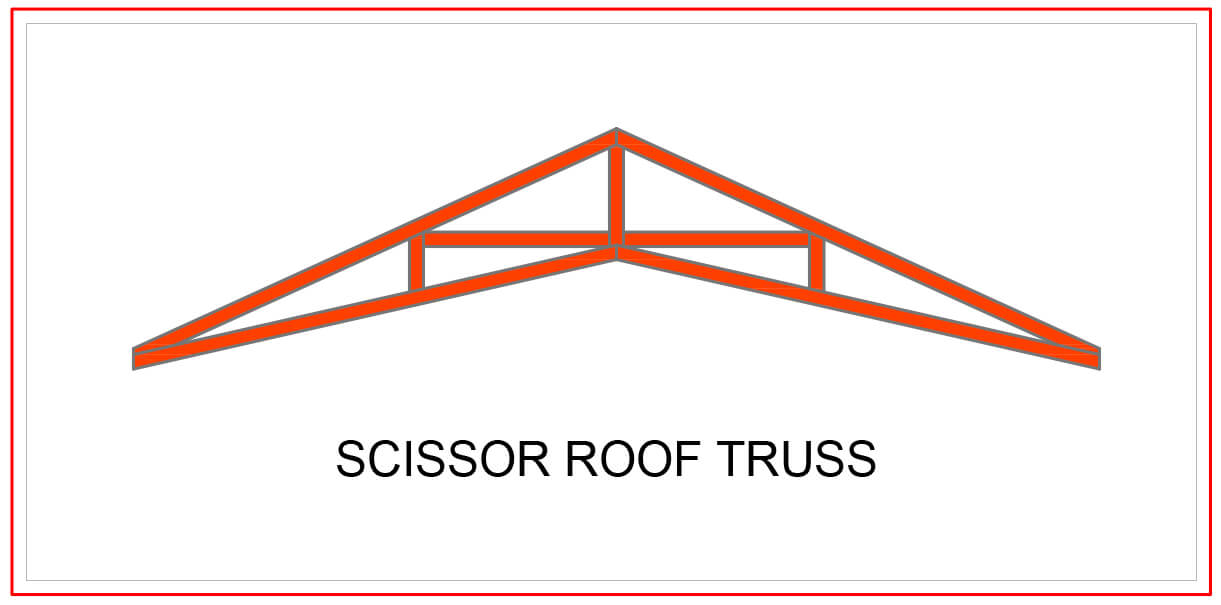

- Scissor roof truss:A scissor truss provides for a vaulted ceiling in the same time frame as standard trusses. Cathedral is one of the best examples of this kind of truss.

4. Materials of roof truss and roof batten

ROOF TRUSS

Roof trusses can also be classified based on the material they are made of, such as timber and steel. Trusses made of timber are usually cheaper while ones made of steel are stronger and have more benefits.

Metal roof truss

ROOF BATTEN

Wood and metal are the most common materials of roof battens. Battens made from plastic or composite materials are also available but less common.

5. Advantages of using steel roof truss and batten

- Optimum strength at minimum cost

- Light yet strong due to its high tensile strength compared to conventional timber trusses

- Versatile, can be used on any scale of building

- Termite-proof and rust-resistant

- Non-combustible material that offers continuous fire resistance

- Environmental friendly as it eliminates the use of timber in buildings

6. Truss and channel roll forming machine of CUNMAC

Our over 15 years of experience in manufacturing roll forming machines is a result of our high-quality awareness to operate in a continuously innovative process. This process is based on market needs and desires for innovation, automation, and quality. Our quality covers not only employees and suppliers but also production methods, products, and partners. All parts of products are fabricated from alloy steel by CNC precision machines. Electrical and hydraulic components derive from reputable brands such as Siemens, Schneider, OMRON, Hitachi, Yuken…

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.

Here are some types of truss roll forming machine that CUNMAC producing:

Truss roll forming machine (for lightweight structure):

Channel roll forming machine (Purlin roll forming)

- C-shape purlin roll forming machine

- U shape roll forming machine

- V shape roll forming machine

- Z shape purlin forming machine

Some specifications about these machines:

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

If you are ready to get more information please contact our consultants today, we would be really happy to assist you.

Hotline: +84 981 402 902

Mail: cs@cunmac.com