Go with Cunmac – Definition, Benefits, and Operation of roll forming machine will be useful information to explore before making any purchasing decision. Let’s find out more with us!

1. What is a roll forming machine?

A method of rolling relating to continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section is the roll forming, also spelled as roll-forming or roll forming.

The strip passes through roll sets placed on successive stands, each set only performing an incremental part of the bend before the desired cross-section (profile) is achieved.

For manufacturing constant-profile parts with long lengths and in large quantities, roll forming is optimal.

For manufacturing constant-profile parts with long lengths and in large quantities, roll forming is optimal.

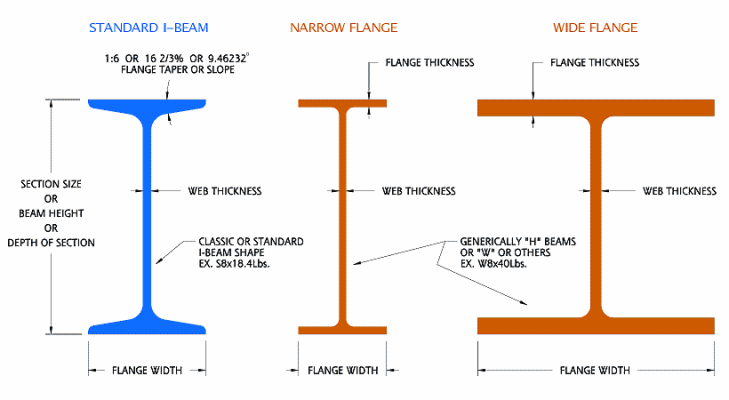

Roll forming machines make specific configurations out of long strips of metal, most commonly coiled steel. In most applications, the required cross-section profile of the piece is specifically designed for the machine to bend the metal as necessary.

Other than roll formation, a variety of metalworking tasks are performed by these machines, including material cutting and roll punching. Roll forming machines operate in a continuous cycle, for the most part. The material is fed into the system where it constantly works its way through each operation’s phases, finishing with the product completed.

2. The benefits of roll forming machines

Energy-efficient because roll forming machines do not expend energy to heat material—the metal shapes at room temperature

An adjustable process and applicable to projects of varying time duration so results in a precise, uniform part.

3. How roll forming machines Work?

Using a number of stations, a roll forming machine bends metal at room temperature where fixed rollers both guide the metal and make the required bends.

As the strip of metal travels through the roll forming machine, each set of rollers bend the metal a little more than the previous station of rollers.

This progressive method of bending metal ensures that the correct cross-sectional configuration is achieved while maintaining the cross-sectional area of the workpiece.

Roll forming machines, typically operating at speeds between 30 to 600 feet per minute, are a good choice for producing large quantities of parts or very long pieces.

Roll forming machines are also good for creating precise parts that require very little, if any, finishing work. In most cases, depending upon the material being shaped, the end product features an excellent finish and very fine detail.

Roll Forming Machine Line Basics

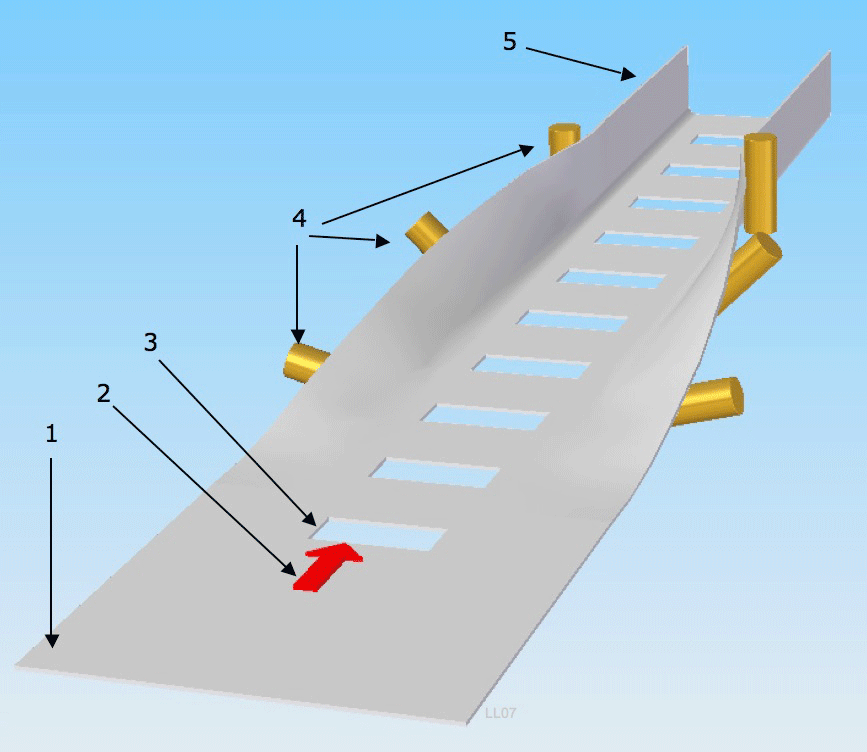

The basic roll forming machine has a line that can be divided into four major parts.

The first part is the entry section, where the material is loaded. The material is usually inserted in sheet form or fed from a continuous coil.

The next section, the station rollers, is where the actual roll forming takes place, where the stations are located, and where the metal shapes as it makes its way through the process. Station rollers not only shape the metal but are the main driving force of the machine.

The next section of a basic roll forming machine is the cut-off press, where the metal is cut to a pre-determined length. Due to the speed at which the machine works and the fact that it is a continuously working machine, flying die cut-off techniques are not uncommon.

The final section is the exit station, where the completed part exits the machine onto a roller conveyor or table and is manually moved.

All CUNMAC – machines are made in Vietnam, our goal is to provide flexible machines with good ease of use of high quality, where our designs and solutions give customers unique benefits.

Latest Events