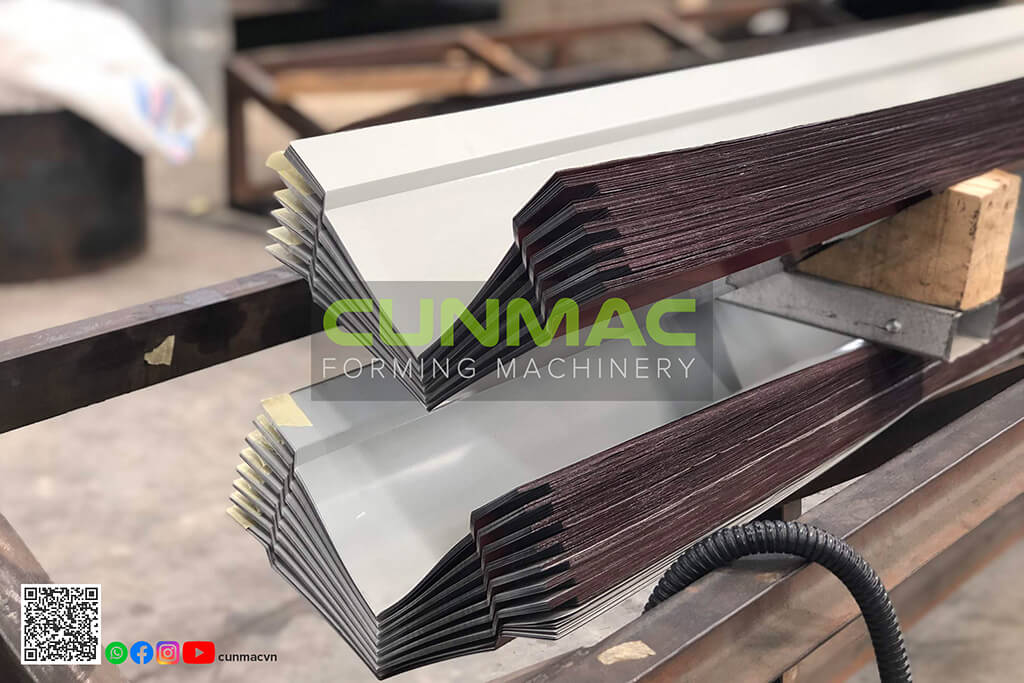

What is a ridge cap?

Ridge cap is a particular shingle that was created to withstand the severe wind that blows across a roof’s ridge. It is not only thicker than a standard shingle, but it is also pre-bent to avoid cracking when folded over the ridge. Ridge cap is made by capping/nok roll forming machine

Shingles placed along the roof’s highest point protect the joint where two slopes meet, helping to block rain and melting snow from seeping inside. Since they are bent over the ridge, this section often wears out more quickly than the rest of the roofing surface.

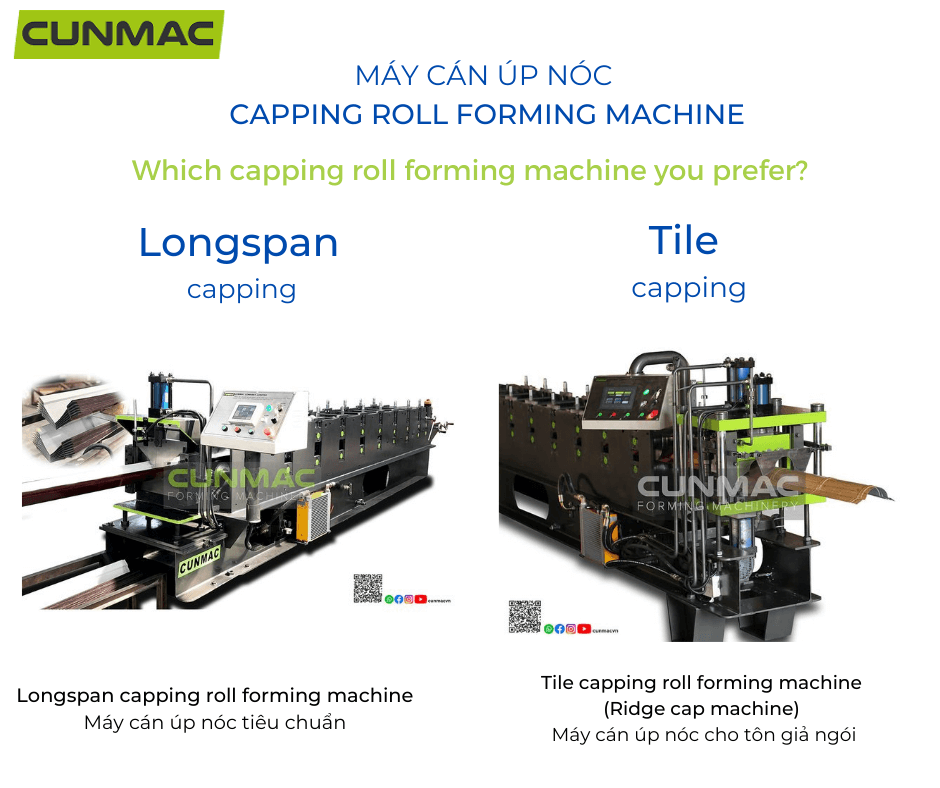

Which kind of ridge capping to choose: Flat ridge or Tile ridge?

Roof capping comes in two main styles:

- Ridge cap type flat capping is commonly used in residential and industrial roofing, go with corrugated and trapezoidal roofing and produced by Flat /Longspan ridge cap roll forming machine

- Ridge cap type tile capping is commonly used in higher aesthetics for villas, especially go with tile roofing. This type is rolled by a Tile capping roll forming machine.

Compare flat material thickness and width between flat capping and tile capping

Ridge capping style can be produced to the customer’s request.

| Longspan capping | Tile capping | |

| Material thickness | 0.15 – 0.5mm (G300-G550) | 0.25 – 0.5mm (G300-G450) |

| Material width | 300; 304; 400; 457mm | 300; 304; 400; 457mm |

How to make ridge capping?

To make a metal roofing ridge cap, we use a Ridge cap machine also called a Metal roof ridge cap roll forming machine, Roof Ridge Cap Roll Forming Machine/ridge cap roll forming machine, Top Cap Roll Forming Machine, Top Hat Cap Roll Forming Machine, Ridge Valley Roll Forming Machine, ridge cap forming machine.

Take a look at the video below to understand how ridge capping is made by a longspan ridge cap roll forming machine

Comparison between Longspan/Flat capping machines and Tile capping machines

| Longspan capping roll forming machine | Tile capping roll forming machine | |

| Total power | 3.7 – 15kw | 5.5 – 15kw |

| Speed | 12- 15m/min | 4 – 8m/min |

| Dimension (LxWxH) | (6-8)x(1.0-1.4)x1.4m | (6-8)x(1.0-1.4)x1.4m |

| Weight of machine | 3 – 12 tons | 3.5 – 12 tons |

| Roller station | 08 – 20 | 10- 20 |

| Material thickness | 0.15 – 0.5mm (G300-G550) Material width150 – 450mm | 0.25 – 0.5mm (G300-G450) |

| Material width | 150 – 450mm | 300 – 457mm |

Read more: Longspan capping roll forming machine

Tile capping roll forming machine

Which type of ridge capping is common in your area? Please comment below and share your opinion.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.