Which parts are required to form a roll forming machine? Let’s go with CUNMAC to discover the key components and their functions in a roll forming machine now!

1. What is roll forming machine?

A roll forming machine or sheet metal roll forming machine is a piece of equipment used in the manufacturing industry to shape metal sheets or coils into a wanted shape or profile.

Roll forming is a continuous process of feeding metal, whether it’s finished, coiled, flat, or otherwise, through a series of rollers, each set of rollers gradually bending the metal into the desired shape.

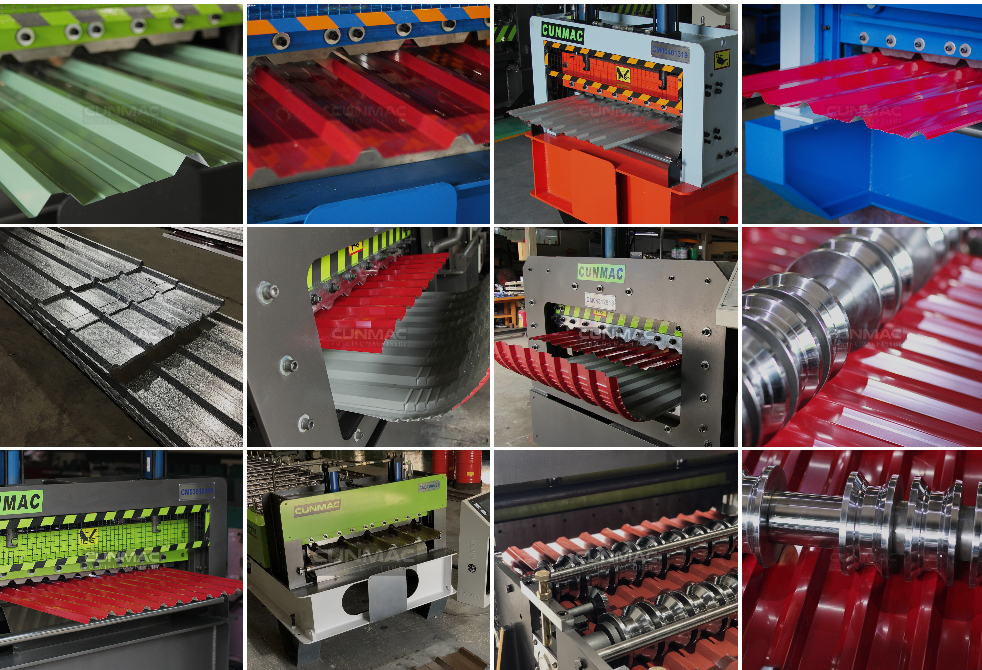

A tile roofing roll forming machine of CUNMAC

2. The importance of using roll forming machine

– Producing consistent, high-quality products with high precision

Roll forming is known for its ability to meet tight tolerances, resulting in uniform and consistent products across production runs. This makes it ideal for applications like assembly line manufacturing where precise fits are crucial. Compared to press braking and extrusion, roll forming produces higher quality products with consistent dimensions and shapes.

– Flexibility and versatility in producing various shapes and profiles

Even complex cross-section profiles that are a challenge or are impossible with stamping can be easily created with roll forming. Besides, roll forming enables custom product manufacturing, flexible production and customization for unique customer requirements.

Read more: Roofing roll forming machine

– High efficiency

Roll forming is a high-speed, low-labor process that enables efficient and high-volume production. Additional processes like punching or notching can be integrated into the roll forming production line, reducing labor demands and producing finished products.

– Energy-saving and waste-reducing

Roll forming is a no-heat process that uses custom-designed rollers to gradually bend metal into its final shape, reducing energy costs. It eliminates tool wear and produces identical parts with minimal wasted scrap and allows for almost any length.

– Faster production times

Roll forming enables faster production times due to its high-speed, continuous process and minimal labor requirements, resulting in efficient and rapid production of consistent and high-quality products.

3. Components of a roll forming machine and their functions

The specific design and configuration of a roll forming machine can vary depending on the manufacturer, model, and intended application. However, there are some general elements of a typical roll forming machine, including:

– Frame:

The frame forms the structure of the roll forming machine and provides stability and support to the entire system.

– Drive system (power source):

The drive system provides the power necessary to rotate the rolls and move the material through the machine. It typically includes motors, gears, and other mechanical components.

– Forming rollers (roll tooling):

Refer to the sets of rolls that shape the material being processed into the desired profiles. Forming rollers are put together in a progressive series to complete a process used to form the end product. Roll tooling can have various configurations and designs depending on the specific profile being formed.

Tile roofing roll forming machine

– Drive rollers:

Drive rollers are used to move the metal through the machine. Some rollformers incorporate the forming and driving rollers into one.

– Shear or guillotine:

If the metal needs to be cut in any way, shape, or form in the roll forming machine, it features a shear, sometimes called a guillotine, to cut the material before or after it passes through the roll forming machine.

– Hydraulic tanks:

Hydraulic tanks aren’t standard on all rollforming machines, but they are commonly added to make the machine faster for higher production. Hydraulics can also automate the machine’s shears.

Read more: YUKEN hydraulic products

– Control System:

The control system monitors and controls various parameters of the roll forming process, such as roll speed, material feed rate, and other settings. It may include a human-machine interface (HMI) for operators to interact with and adjust the machine settings.

Control system of CUNMAC roll forming machine

– Safety Features:

Roll forming machines may also include safety features such as emergency stop buttons, guards, sensors, and interlocks to ensure safe operation and protect operators from potential hazards.

4. Roll forming machine of CUNMAC

As a roll forming machine company, CUNMAC Machinery also has a wide range of roll formers, including:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

Slitting & cutting to length machine

Watch more: Slitting and cutting to length machine combined with auto decoiler

Some specifications about these machines:

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

5. About CUNMAC Machinery

We, a roll forming machine manufacturer, customize design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries. All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.

If you are ready to get more information please contact our consultants today, we would be really happy to assist you.