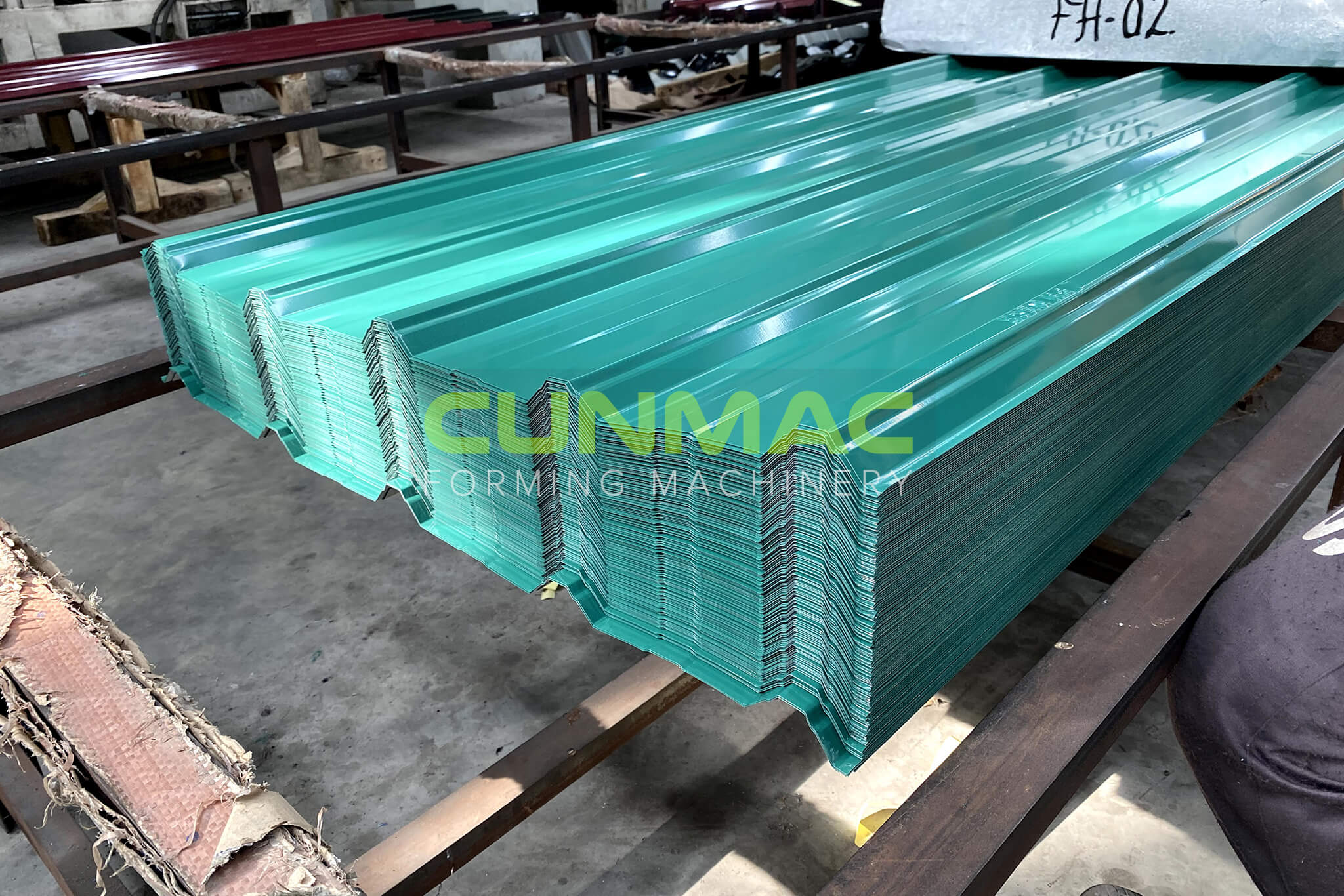

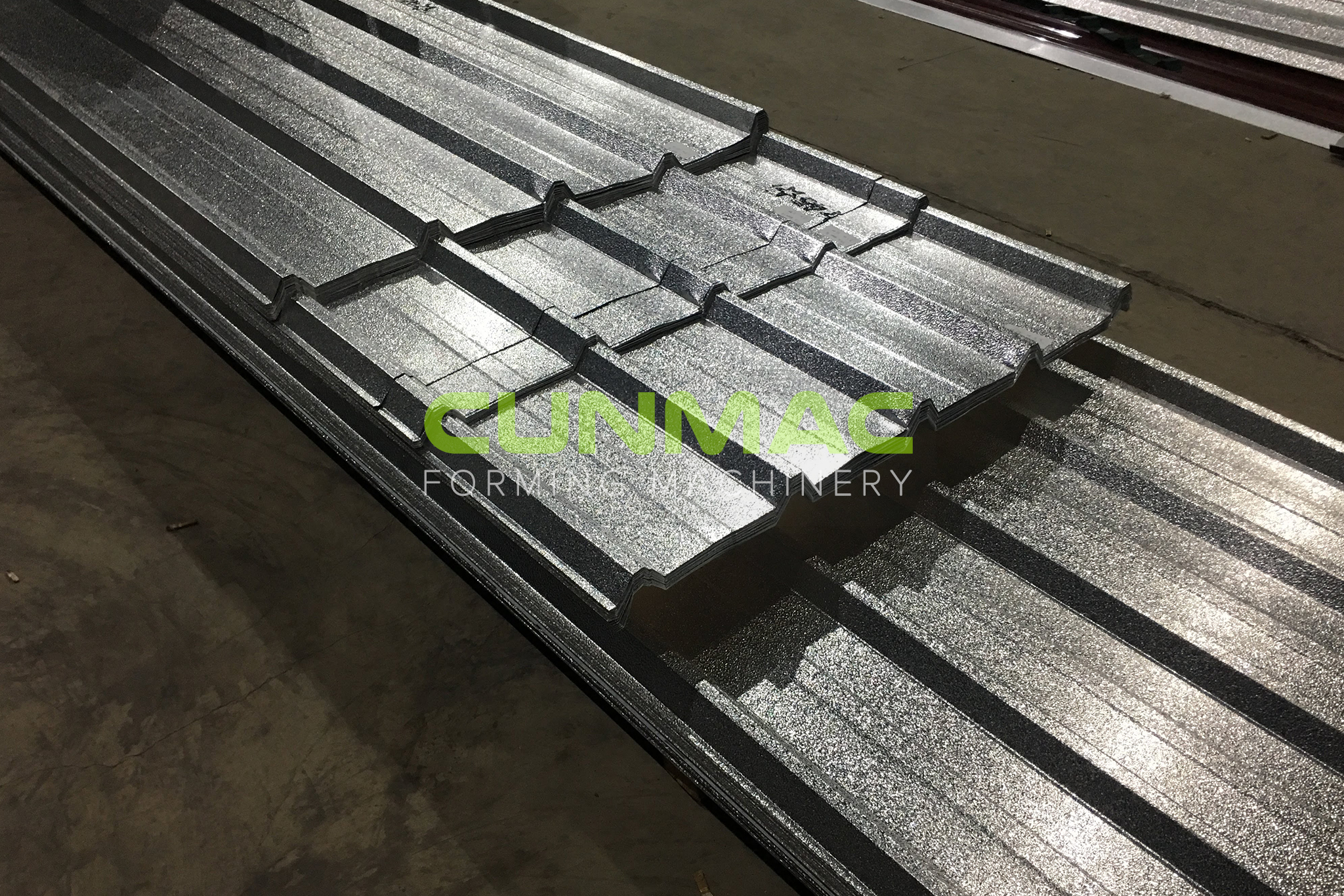

Trapezoidal Profile Roofing Sheets are profile sheets that have trapezoidal shaped profile shape and these are coated with multiple beautiful colors to give attractive appearance. These sheets are available in white, grey, green, blue, terracotta, ivory, brown and more beautiful colors. These roofing sheets provide the perfect combination with the roofing to match the attractive look of the houses.

Material Structure:

The materials used on surface layer are ultra-weather resin which helps to prevent the effect of UV rays coming from sun and along with reduce the coefficient of heat conductivity. All these notable features ensure durability and excellent resistance to chemical corrosion. The intermediate and underlying layers are made up of materials that ensure excellent strength and excellent insulating nature.

Features :

|

Applications :

|

|

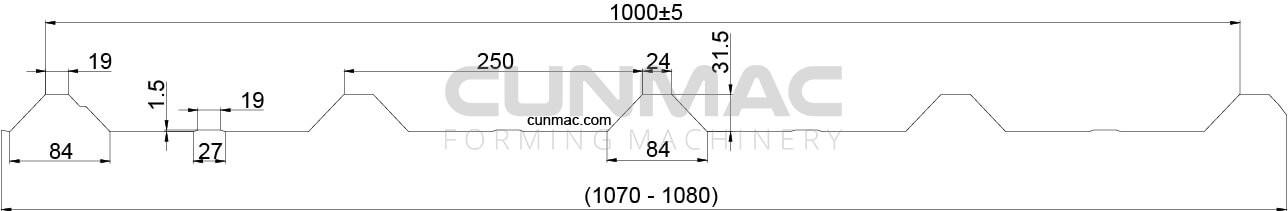

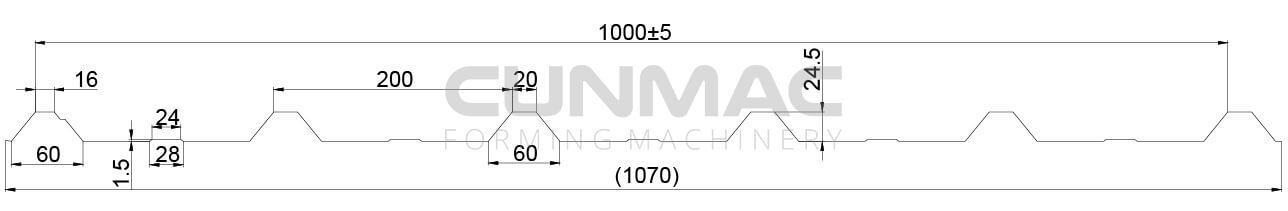

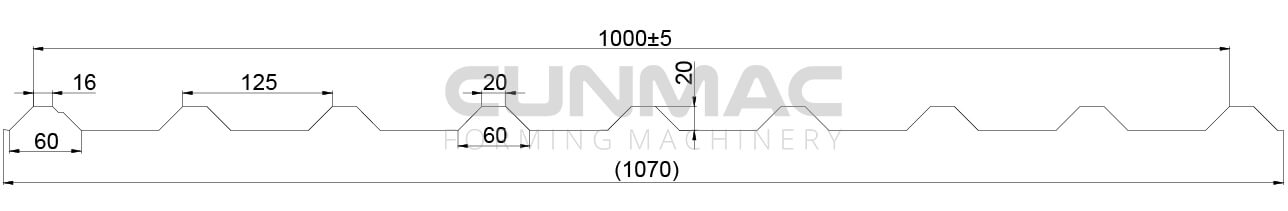

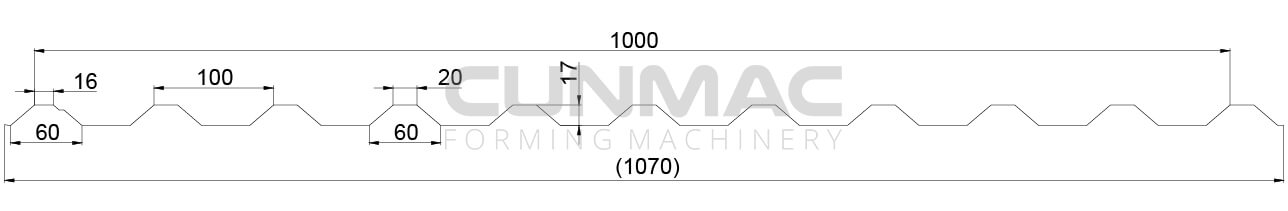

Trapezoidal profile’s drawing

How to make Trapezoidal Profile Roofing Sheets?

Trapezoidal Roofing Roll Forming Machine can create trapezoidal profiled roofing sheets by forming metal/steel coil. They can be called differently upon countries as below:

- Rib-type Roofing Roll Forming Machine

- Spandek Roofing Roll Forming Machine

- Trimdek Roofing Roll Forming Machine

- 4 Angles Roofing Roll Forming Machine

- 5 Wave Roofing Roll Forming Machine

There are various rib-type profiles depending on the country, including 5/6/7/8/9/10/11/12/13/14 rib type, but the most common is the 5 rib-type profile.

Watch video below to understand how Rib-type profile roll forming machines operate:

Rib-type profile roll forming machine is fully automatic and is easy to operate with a friendly HMI panel, consists of one decoiler, sheet guiding equipment, roll forming section, PLC control system, Hydraulic cutting, collection table. Step by step, the rollers inside the machine will shape sheet metal to become a metal roofing sheet panel.

Their main advantages are beautifully customized designs, easy and stable operation with a strong body frame, and reasonable price. There are 3 models as below:

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 5.5 – 7.5kw | 7.5 – 11kw | 11 – 22kw |

| Speed | 16 – 18m/min | 22 – 24m/min | 44 – 46m/min |

| Dimension (LxWxH) | (9-11)x(1.6-2.2)x1.8m | (9-11)x(1.6-2.2)x1.8m | (9-11)x(1.6-2.2)x1.8m |

| Weight of machine | 6 – 8 tons | 7 – 10 tons | 9 – 12 tons |

| Roller station | 16 – 18 | 18 – 21 | 20 – 24 |

| Material thickness | 0.15 to 0.7mm (G300-G550) | 0.15 – 0.7mm (G300-G550) | 0.15 – 0.7mm (G300-G550) |

| Material width | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm |

| Transmission system | Hydraulic motor | Hydraulic motor | Electric motor with gear box |

| Cutting system | Hydraulic cylinder (front cutting) | Hydraulic cylinder (rear & front cutting) | Electric motor with gear box (rear & front cutting) |

| Control system | Automatic with PLC, HMI | Automatic with PLC, HMI, Inverter | Automatic with PLC, HMI, Inverter |

Read more details here: Trapezoidal/ Spandek/Trimdek/4 angles roofing roll forming machine

Now that you understand the Trapezoidal ( Rib-type) Roofing Roll Forming Machine and you are ready to get a quotation. Our sales reps have decades of experience with metal panel roll former and would be happy to assist you. For more information on different types or you are ready to purchase please contact our consultant today.

To give a better quotation and meet exactly your requirements, could you advise detailed information as below:

- Which kind of roof roll forming machines do you need?

- Profile or sample’s pictures

- Thickness and width of the coil

WHY CUNMAC?

As a global manufacturer of roof panel roll forming machines with over 15-year experience, CUNMAC believes in building partnerships and provides comprehensive customer services. Through resources, innovative solutions, and expert service, we are committed to a stable production with good quality and great services. CUNMAC products have been trusted and used by customers all over the world, which demonstrates CUNMAC’s reliability and trustworthiness.

Hotline: +84 981 402 902

Mail: cs@cunmac.com

Factory: 331, Lien Huyen street, Thuan An city, Binh Duong province, Vietnam