Dive into the differences between one double layer and two separate single layer roll forming machines. Get insights to optimize your operations. Read the article for details!

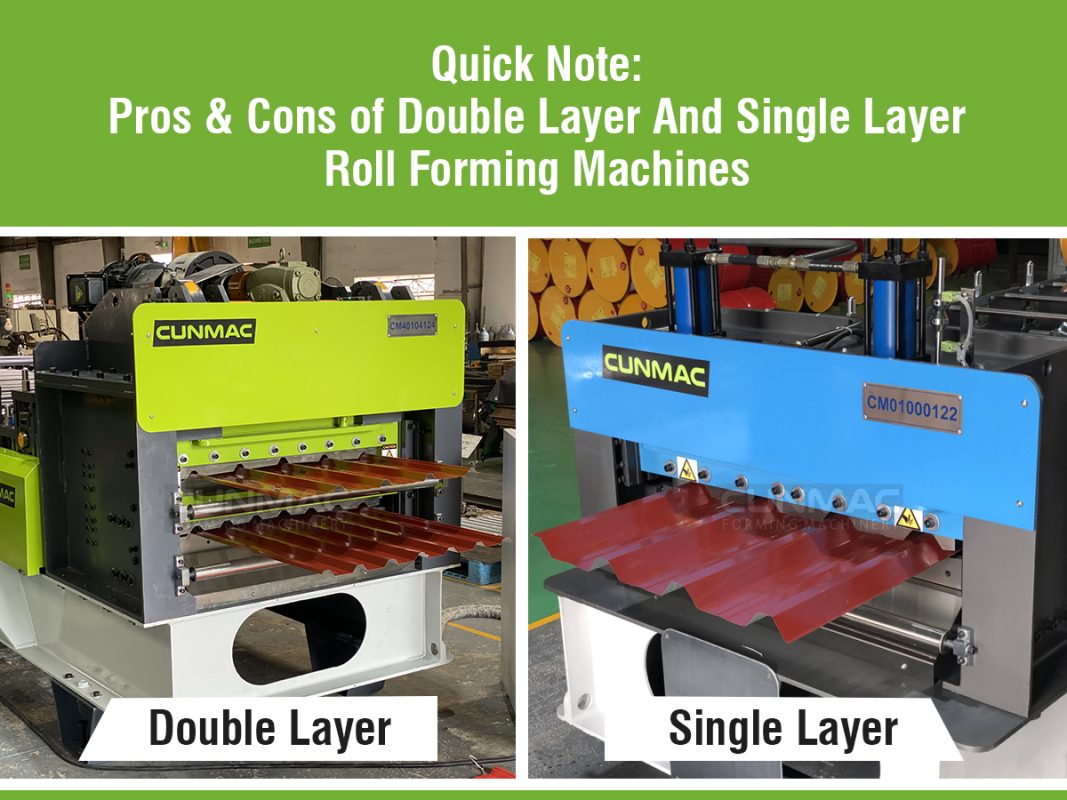

DOUBLE LAYER ROLL FORMING MACHINE

A double layer roofing machine is designed to produce two different roofing profiles in only one single machine.

Other names: double deck roll forming machine, dual level roll forming machine, double design roll forming machine

Roofing types applied: trapezoidal roofing, corrugated roofing, tile roofing

Double layer roofing machine (trapezoidal and corrugated roofing)

Read more: Double layer roll forming machine

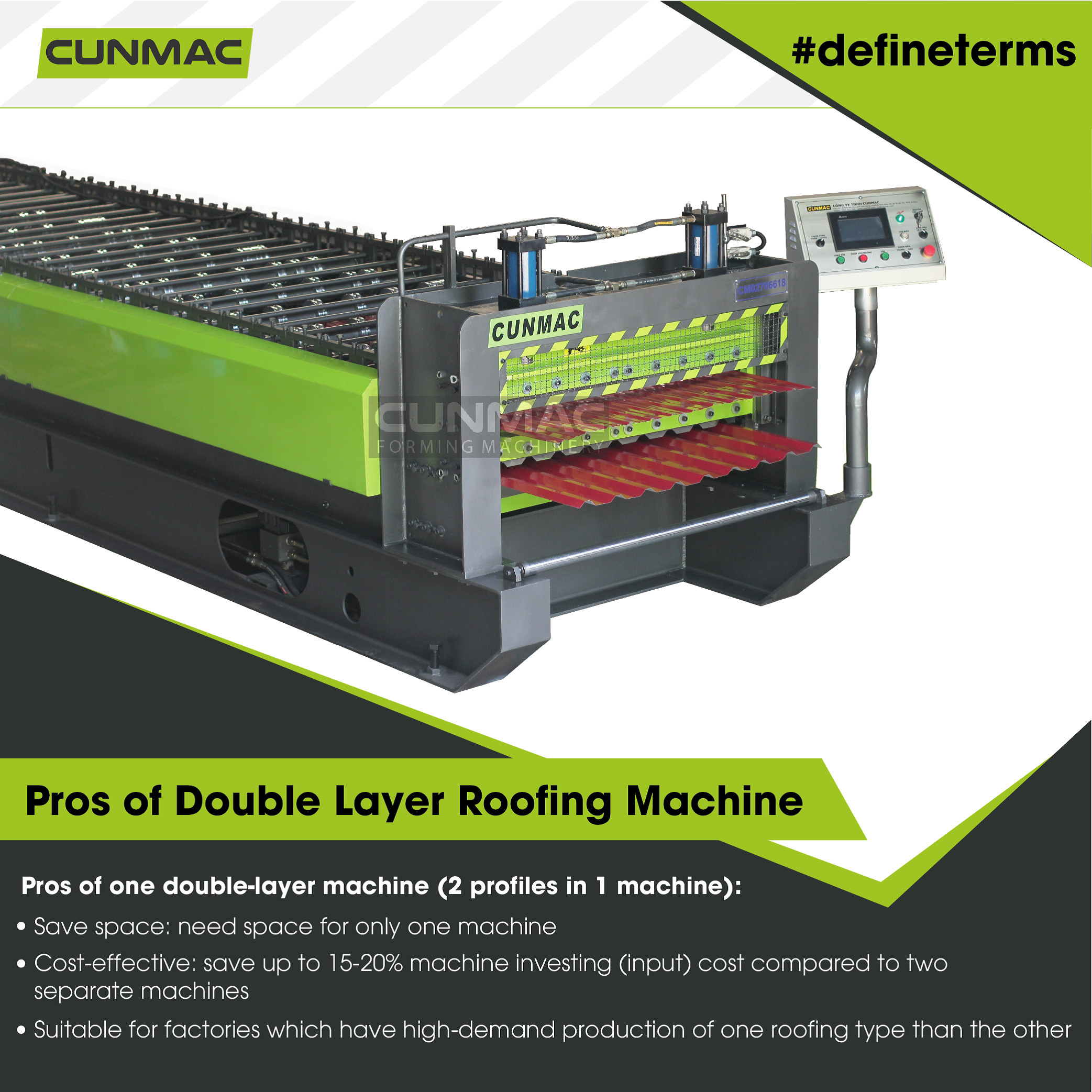

Advantages of double layer roll forming machine (2 profiles in 1 machine):

– Save space: need space for only one machine

– Cost-effective: save up to 15 – 40% machine investing (input) cost compared to two separate machines

– Suitable for factories which have high-demand production of one roofing type than the other

Advantages of double layer roofing machine

Disadvantages of double layer roll forming machine (2 profiles in 1 machine)

– Only operating one type of roofing at a time

– Affecting both layers if the machine needs maintenance

Disadvantages of double layer roofing machine

SINGLE LAYER ROLL FORMING MACHINE

A single layer roll forming machine produces a single roofing profile continuously, efficiently shaping metal sheets for roofing applications.

Separate machines can be used to produce a wide range of panels: trapezoidal, corrugated, tile, klip lok, seamlock, snaplock, floordeck…

Snap lock roll forming machine – CUNMAC Vietnam

Read more: Snaplock roll forming machine

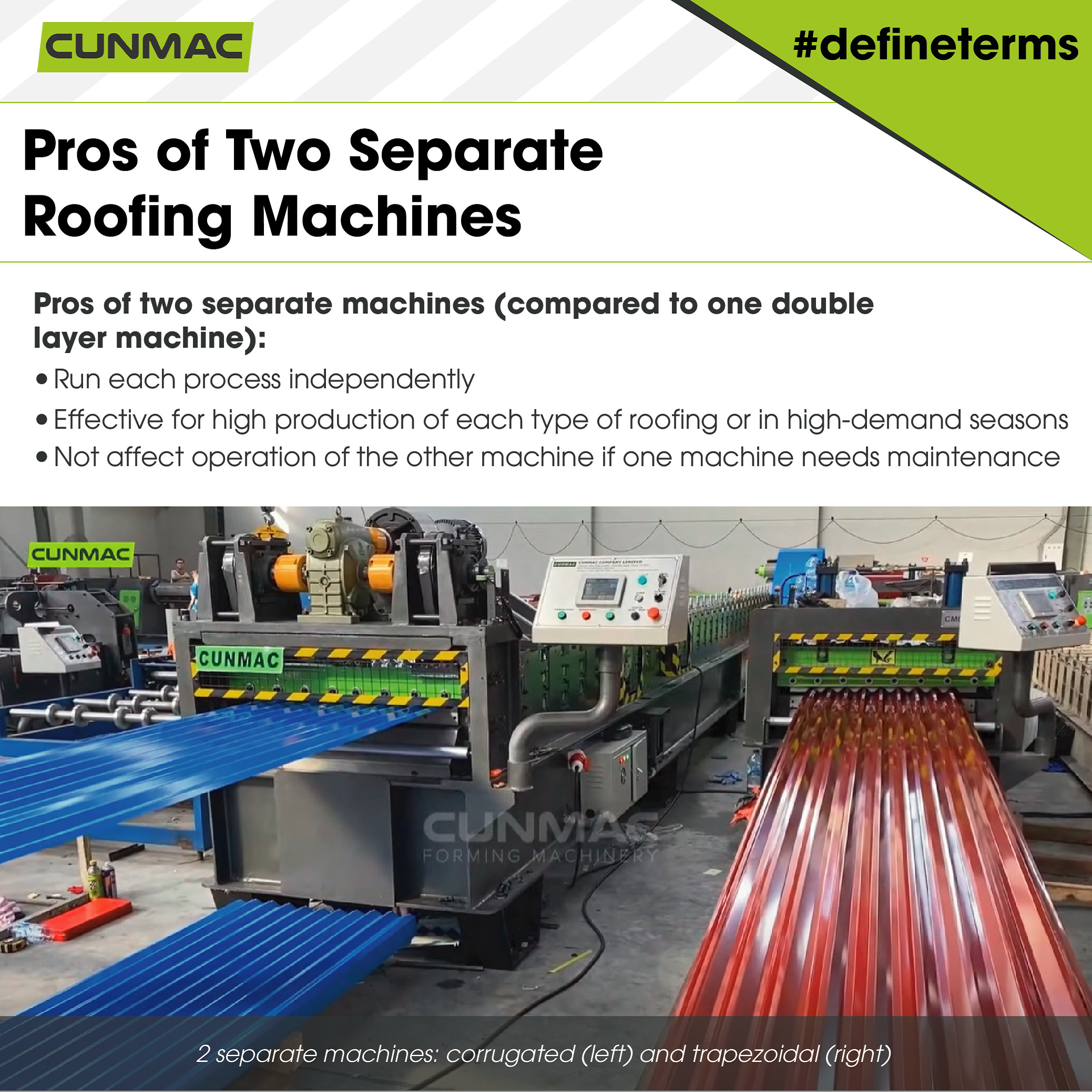

Advantages of two separate single layer machines (compared to one double layer machine):

– Run each process independently

– Effective for high production of each type of roofing or in high-demand seasons

– Not affect operation of the other machine if one machine needs maintenance

Advantages of two separate roofing machines

Read more: Electric roofing machine (non-hydraulic)

Disadvantages of two separate single layer machines (compared to one double layer machine):

– Need more space in the factory

– Require higher cost for investing and operating than a double layer machine

Advantages of two separate roofing machines

Read more: Tile roofing roll forming machine

Through this post, CUNMAC team has given you differences between one double layer and two separate single layer roll forming machines. Don’t forget to follow our series #defineterms to update more useful information.

This series belongs to CUNMAC Vietnam.

CUNMAC Vietnam – Innovative engineering machine manufacturer (OEM), to customize design and provide solutions for roll forming machines to over 30 countries in the world.

Channel roll forming machine of CUNMAC with 2 options:

standard with no safety cover (left) and special with safety cover (right)

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.