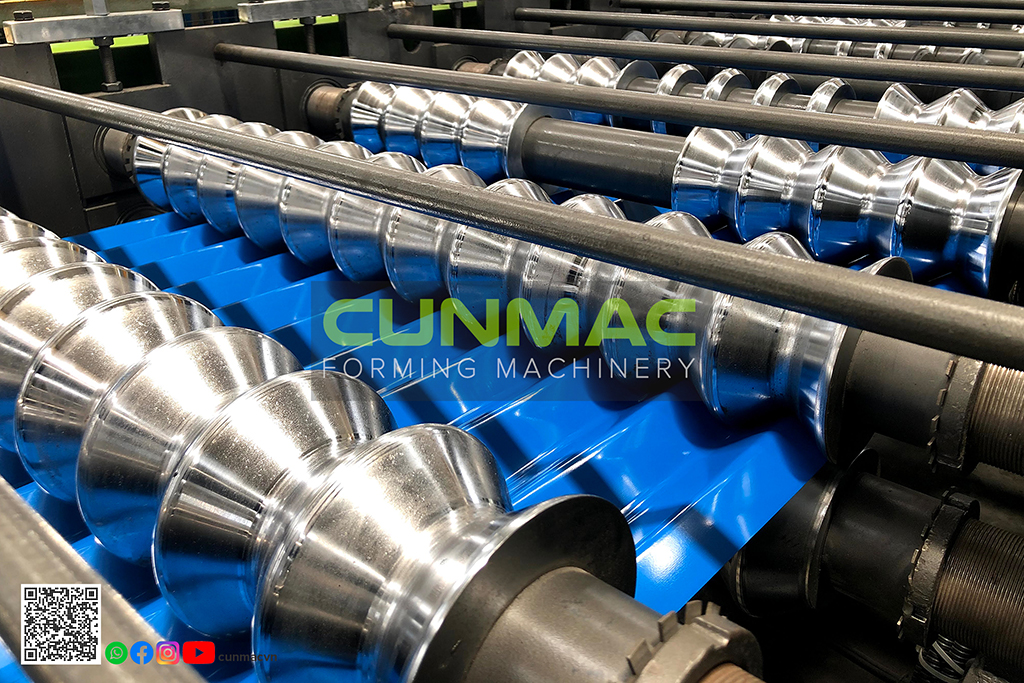

Let’s go with CUNMAC to explore interesting things and some popular terms about material thickness in roofing roll forming machines!

MATERIAL THICKNESS IN ROOFING ROLL FORMING MACHINE

The material thickness for a roofing roll forming machine can vary depending on the specific machine and application.

Typical sheet thicknesses range from 0.2mm to 0.6mm.

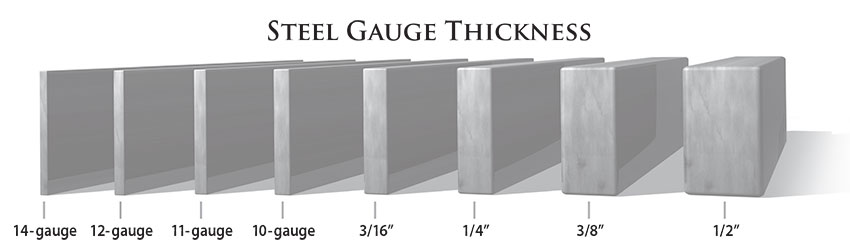

Gauge is also used to measure the thickness of materials.

Some steel gauge thickness

SOME POPULAR TERMS IN MATERIAL THICKNESS

1. Yield strength

Yield strength is the maximum stress that can be applied before it begins to change shape permanently.

G250, G300 or G550 are usually used to represent different grades of galvanized steel.

These grades indicate the minimum yield strength of the steel in megapascals (MPa).

For example:

- G300: minimum yield strength of 300 MPa. Used for moderate strength applications like light structural components and general manufacturing.

- G550: minimum yield strength of 550 MPa. Used for applications requiring greater structural strength, such as buildings, bridges, and heavy-duty industrial equipment.

Material thickness: 0.15 – 0.6mm (G300 – G550)

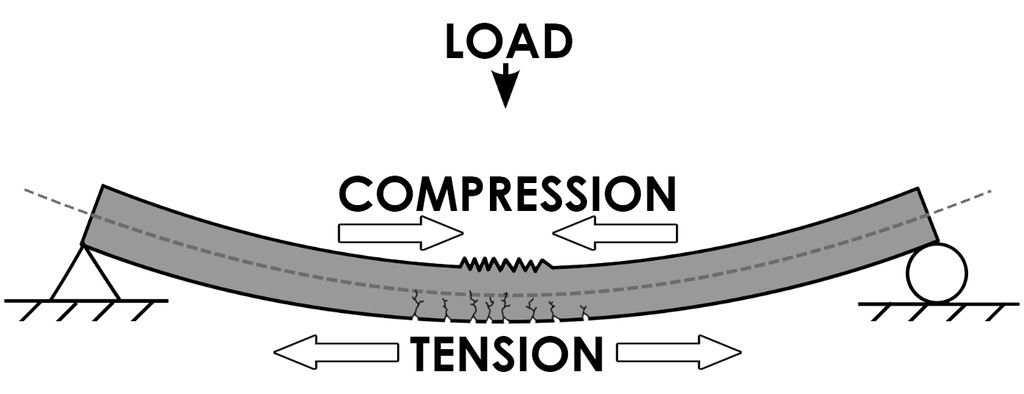

2. Tensile strength

Tensile strength describes the maximum stress that a material can handle before breaking.

It marks the transition from temporary to permanent deformation. Once steel exceeds its tensile stress, it breaks apart.

Tensile strength

(G300 – G550)

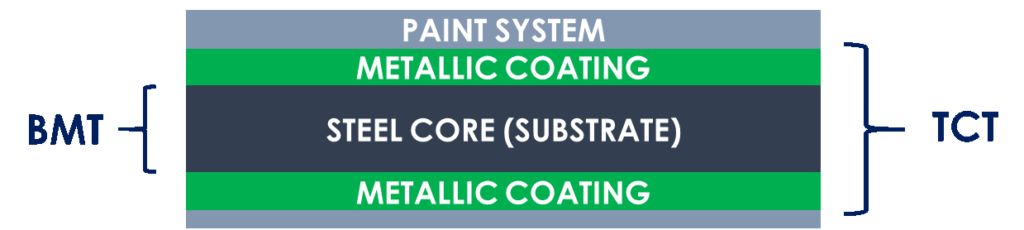

3. Base Metal Thickness (BMT)

BMT measures the thickness of the metal itself before any protective layers and paint are applied.

For example, 0.25mmBMT indicates a steel base that is 0.255mm thick without coatings, primers or paint.

BMT is an accurate indication of material strength.

Base Metal Thickness (BMT)

4.Total Coated Thickness (TCT)

TCT refers to the overall thickness of a material including both the base metal and any metallic coating layers.

The term After Paint Thickness (APT) is also used in place of TCT but this is less common.

Total Coated Thickness TCT and BMT

Through this post, CUNMAC team has given you common things about material thickness in roofing roll forming machine. Don’t forget to follow the next issue of our series #defineterms to update more useful information.

This series belongs to CUNMAC Vietnam.

CUNMAC Vietnam – Roll Forming Machine Manufacturer has 15 years experience to ensure machine quality and customer satisfaction all over the world.

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.