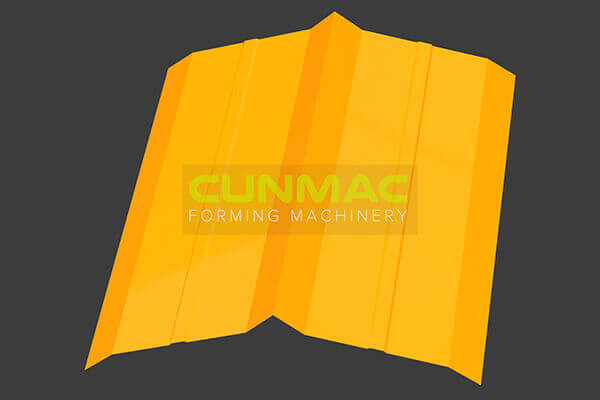

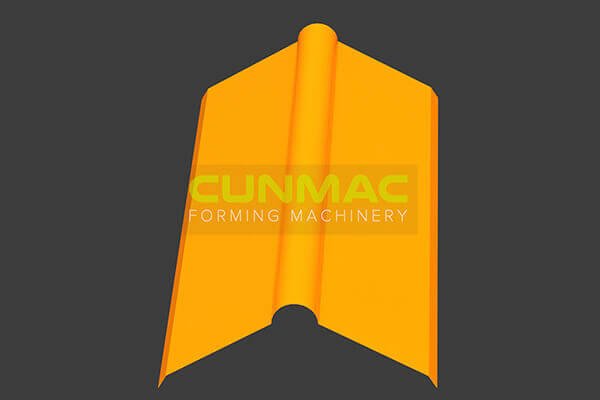

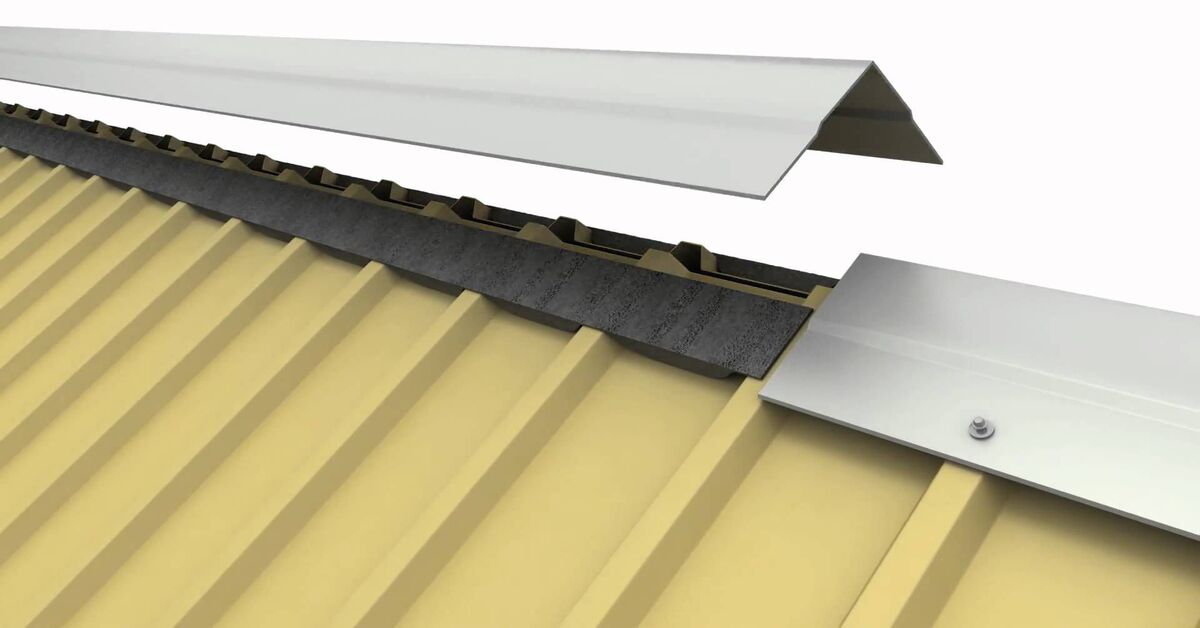

An auto or manual capping roll forming machine plays an important role to manufacture long sheets of metal with a specific profile for capping roofs. These sheets are designed to cover the ridge of the roof, where two sloping sides meet. They come in different styles, with most having a ribbed or curved design.

Snap lock used for roofing and wall cladding

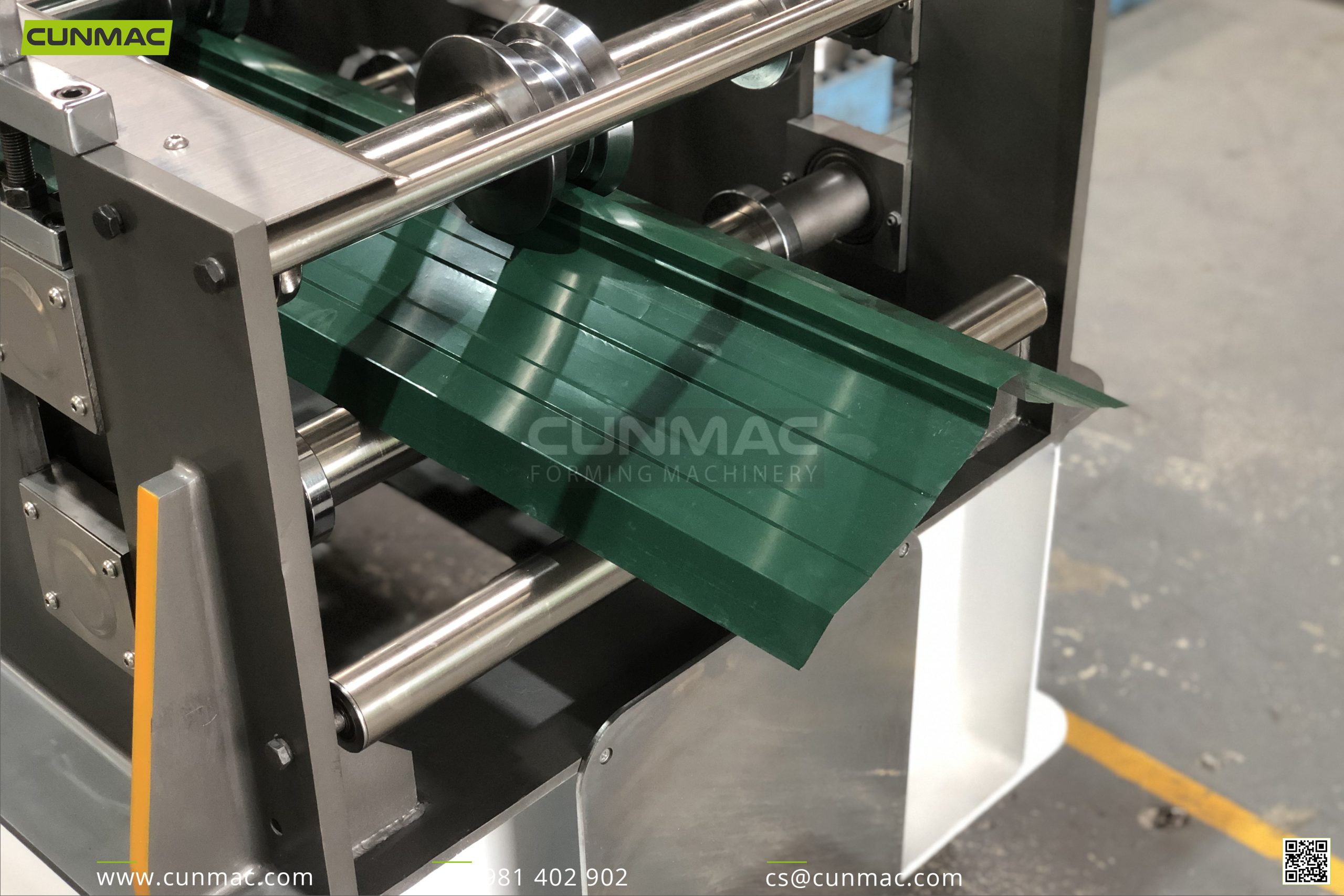

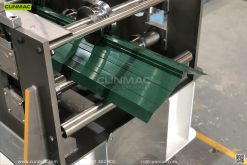

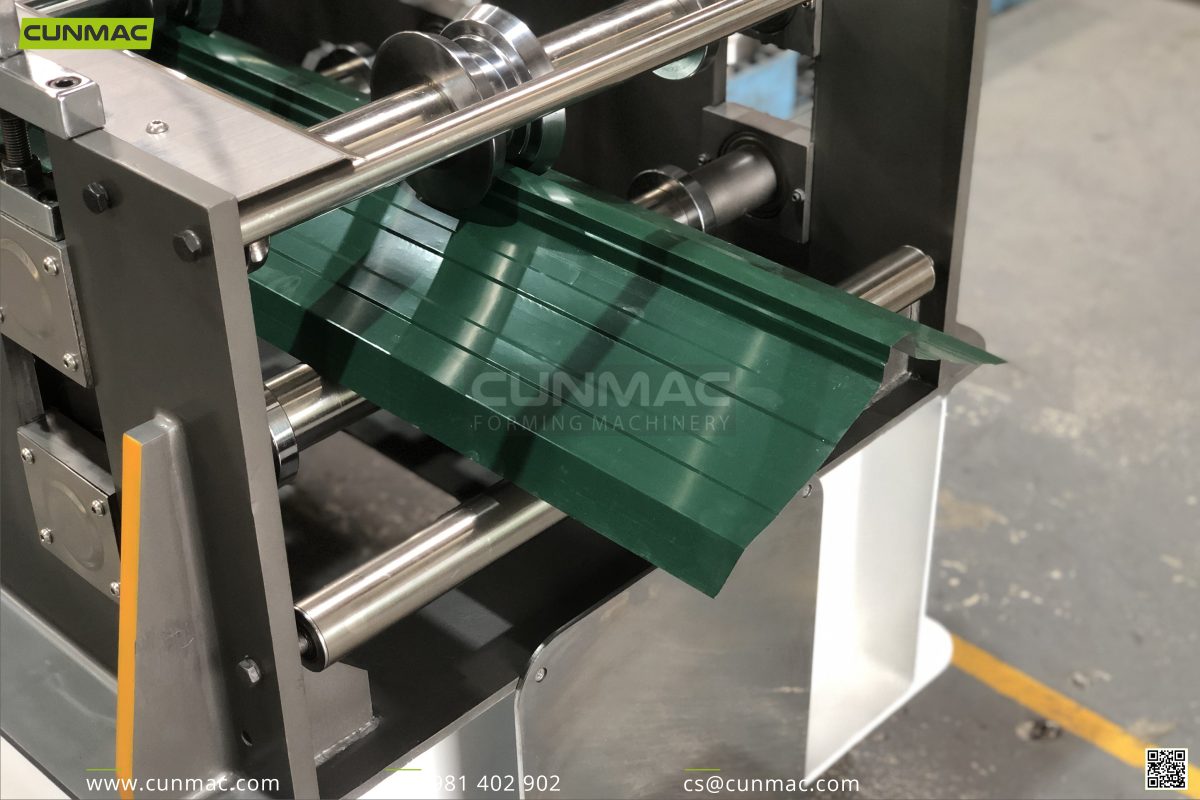

Manual capping roll forming machine is a longspan capping machine with manual control system and operating system, an affordable and space-saving choice for factory owners.

Manual capping roll forming machine – CUNMAC Vietnam

Slitting and Capping line is also a useful and popular line that customers often choose:

Some typical kinds of CUNMAC capping roll forming machines:

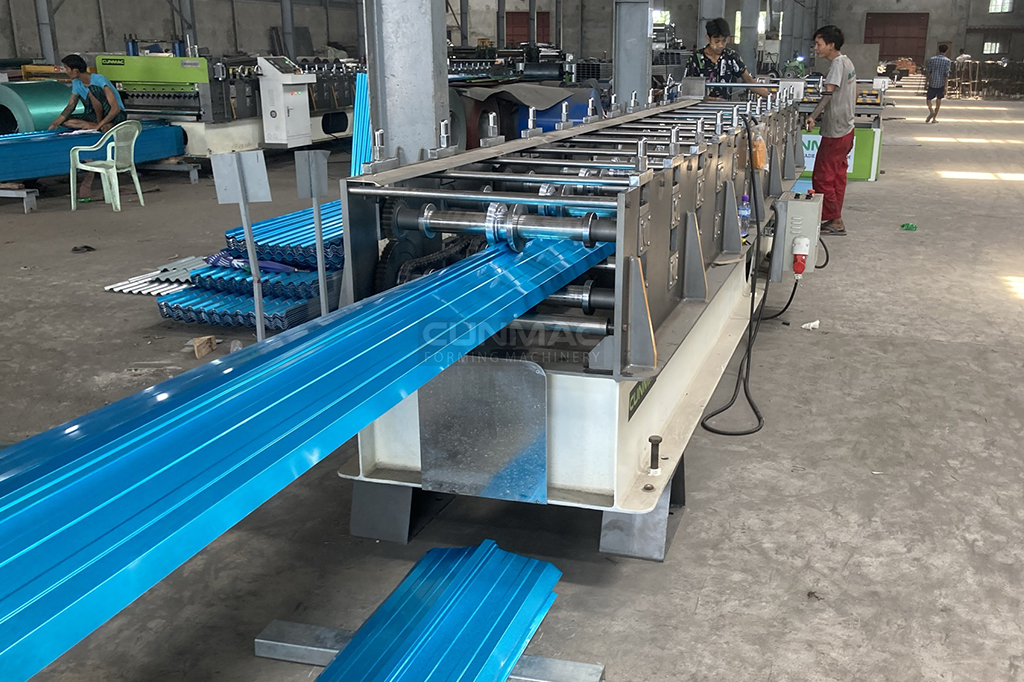

- Longspan capping roll forming machine (automatic)

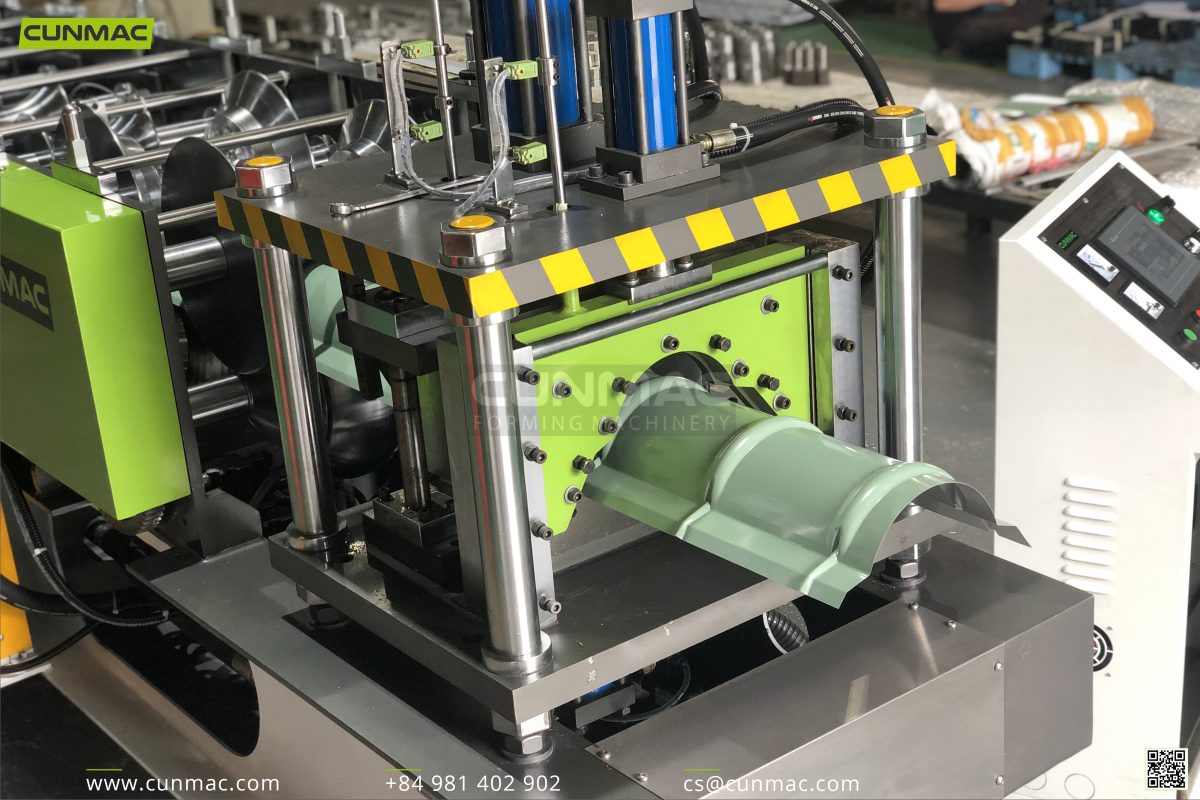

- Tile ridge capping roll forming machine

- Manual capping roll forming machine

Auto longspan capping roll forming machine is a common type of capping roll forming machine, produced by CUNMAC, is fully automatic and is easy to operate with Inverter, PLC, HMI, instead of manual control system and operating system.

Auto longspan/simple capping roll forming machine – CUNMAC Vietnam

Tile ridge capping roll forming machine is used to make special kind of metal sheets that resemble actual roof tiles for capping the ridge of a roof. Like the longspan capping machine, it is made with fully automatic functions.

Tile ridge capping roll forming machine – CUNMAC Vietnam

Read more: Tile ridge capping roll forming machine

Machine video

SPECIFICATIONS & EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Cutting blade is fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

| SPECIFICATIONS | |

| Total power | 3.7 – 5.5kW |

| Total weight | 3.0 tons |

| Dimension (LxWxH) | 6.0×1.2×1.6m |

| Station quantity | 8 – 12 stations |

| Thickness of material | 0.15 – 0.6mm (G300 – G550) |

| Material width | 300; 304; 400; 457mm |

| Speed | 18 – 20m/min |

| Frame structure | I beam |

| Control system | Forward and backward by remote control |

| Operating system | Sheet by sheet |

ABOUT CUNMAC MACHINERY

CUNMAC products are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

We offer a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.