What is a AG panel roll forming machine?

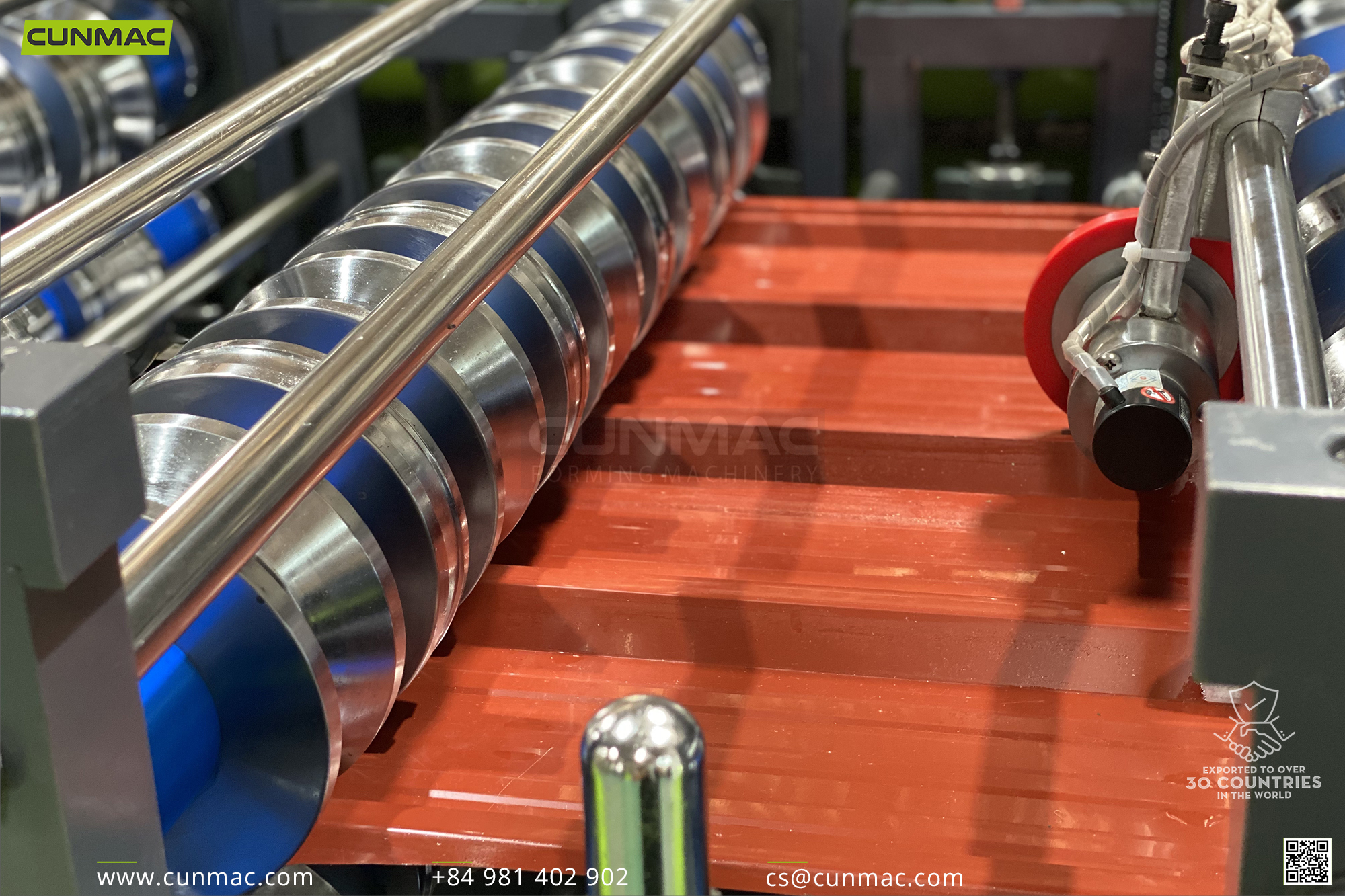

The AG Panel Roll Forming Machine is a high-performance automatic production line designed to manufacture AG roofing sheets with precision, consistency, and speed. Built with advanced automation and durable materials, this machine ensures seamless production of AG panels – a popular roofing profile used in both residential and industrial construction.

CUNMAC AG Panel Roll Forming Machine – High precision roofing sheet forming system

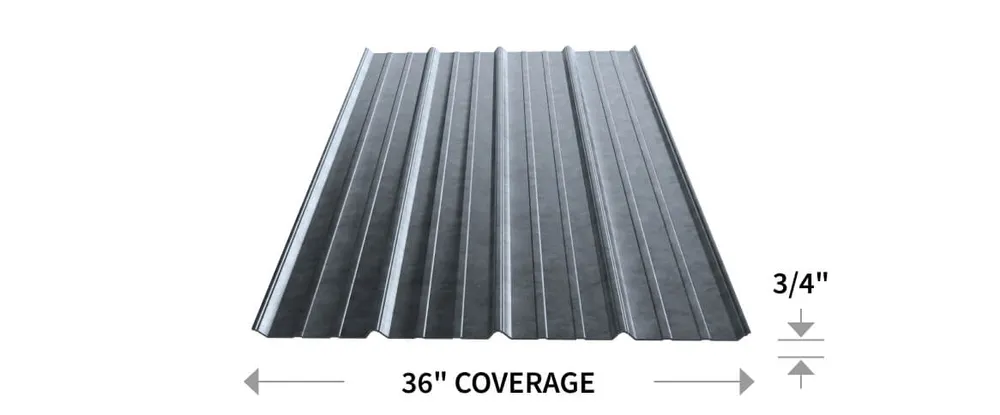

AG panels, also known as AG roofing panels or AG metal sheets, feature a symmetrical rib design that provides excellent strength, water drainage, and a clean architectural look. The CUNMAC AG panel roll forming machine automates the entire forming and cutting process, allowing users to create panels of any custom length with minimum waste and maximum efficiency.

AG Panel Roll Forming Machine CUNMAC full view high speed roofing line

Read more: IBR roll forming machine

Designed for superior performance, this panel features a 36″ effective coverage (≈ 914 mm), the optimal width for roofing and wall applications. Each sheet delivers precise overlap and perfect alignment, helping you save materials, reduce installation time, and achieve a clean, professional finish on every project.

Nguồn: shop.gabrielbuildingsupply

This machine is ideal for manufacturers seeking to upgrade from manual or semi-automatic systems to a fully automated, PLC controlled production line that guarantees high output and consistent quality.

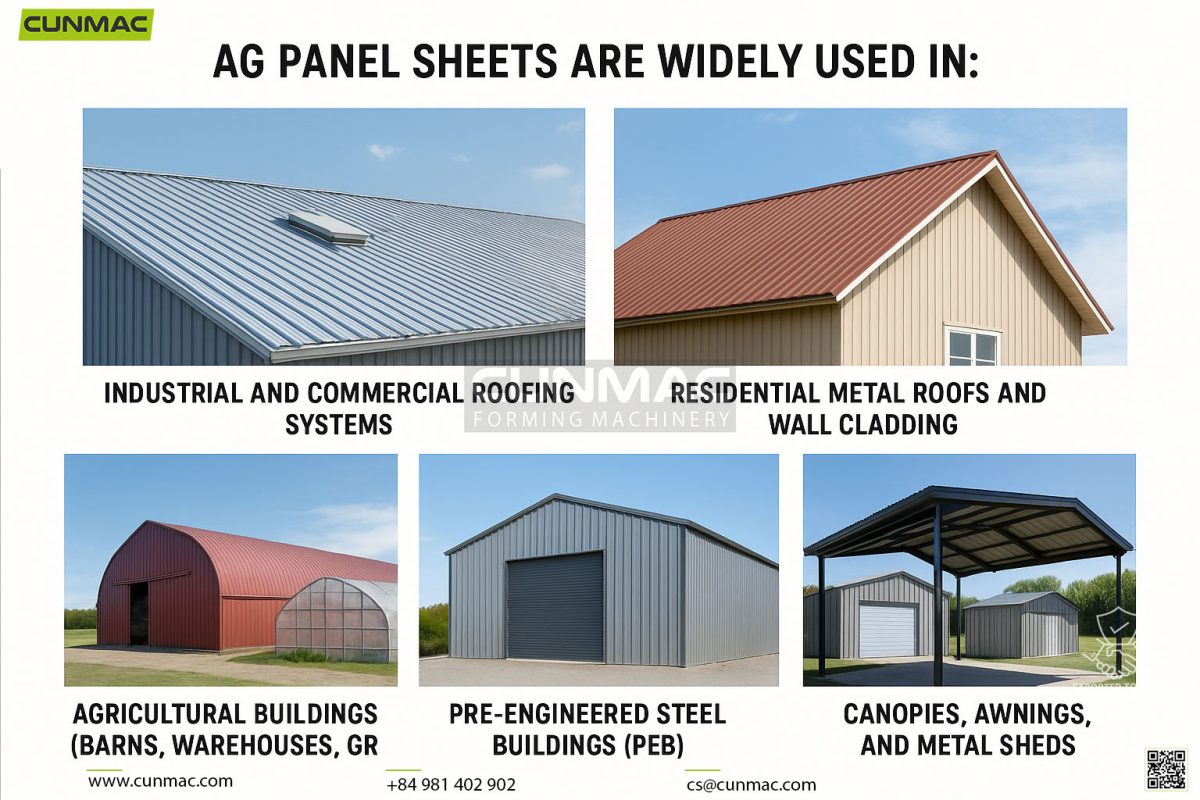

AG panel sheets are widely used in:

- Industrial and commercial roofing systems

- Residential metal roofs and wall cladding

- Agricultural buildings (barns, warehouses, greenhouses)

- Pre-engineered steel buildings (PEB)

- Canopies, awnings, and metal sheds

The panels produced by CUNMAC machine ensure excellent water drainage, corrosion resistance, and aesthetic appearance, suitable for all climate zones.

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60 – 62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |

| Items | Details |

| Total power | 5.5 – 7.5kW |

| Total weight | 7.0 tons |

| Dimension (LxWxH) | 10.0 x 2.0 x 1.6m |

| Station quantity | 18 – 22 stations |

| Thickness of material | 0.2 – 0.7mm (G300-G550) |

| Material width | follow drawing |

| Speed | 20 – 24m/min |

| Frame structure | I beam |

| Control system | Automatic with PLC, HMI, hydraulic |

| Cutting system | Hydraulic cylinder (entrance & exit cutting) |

| Transmission system | Hydraulic motor/Gear motor |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | SCHNEIDER (Japan) |

| Electric motor | HITACHI/TOSHIBA/TECO/HYOSUNG |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blade | SKD11 Japan |

| CB/MCCB | FUJI (Japan) |

ABOUT CUNMAC MACHINERY

CUNMAC products reach 10% of their sales in the domestic market (Vietnam) and 90% are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

Cunmac proudly provides Batten (reng) roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

We offer a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.