Go with CUNMAC – Exploring insights of metal decking, from roof deck to floor deck with common types, applications and some key characteristics.

1. What is metal decking? Applications of metal decking

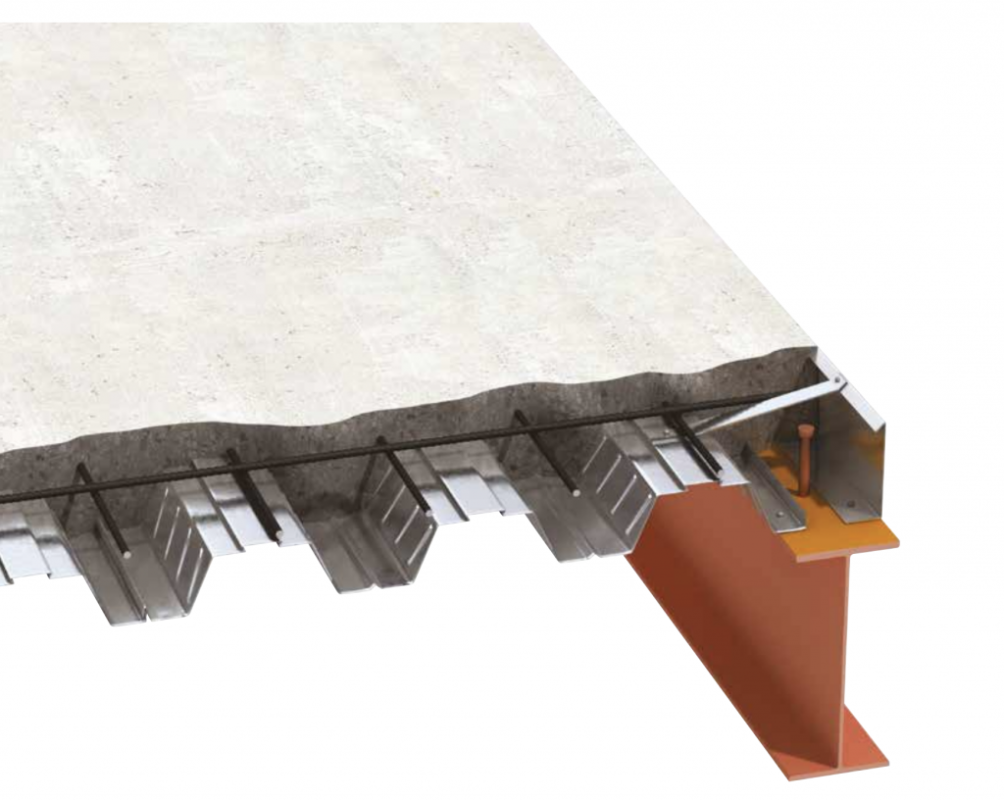

Decking is a term usually used in constructions and structures. Metal decking is a specific type of decking. It refers to a metal sheet with corrugations, which are grooves or ridges.

Metal decking is supported by other materials such as beams and joists to provide roof support insulation or bond with concrete to form composite metal floor/wall cladding.

Generally, metal deck or steel deck is used to strengthen and enhance building durability, suitable for most building types, for one-story or multi-story structures.

Roof deck and Floor deck applications in constructions

Read more: Decking roll forming machine

2. Types of metal decking

Different metal decks have been designed to suit various purposes and styles over the years. Based on the purpose, metal decking can be classified into roof deck and floor deck.

2.1 Roof deck

Metal roof decking is a popular choice in commercial and industrial buildings. It provides a sturdy base for roofing systems to be built on.

Thanks to its strength, light weight and affordability, metal roof deck is suitable for various structure types such as flat roof, pitched roof…

There are four common types of metal roof deck: B-Deck, N-Deck, F-Deck and 1’’ Roof Deck

Metal roof deck

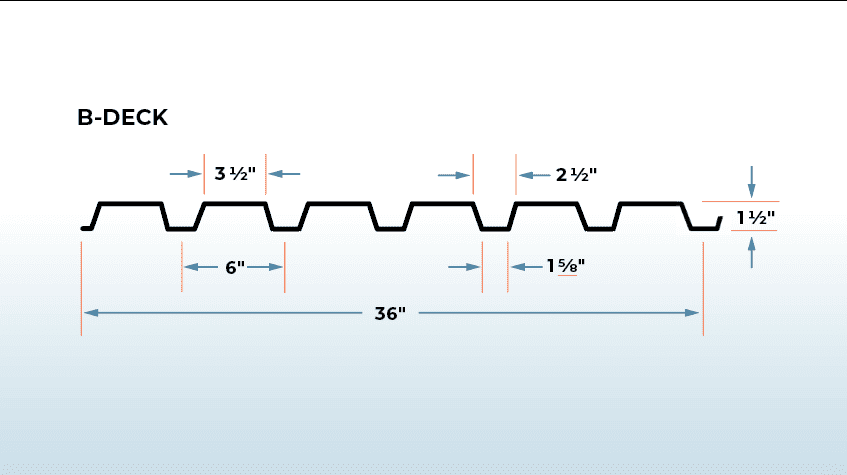

B-Deck

Among these types of roof decking, B-Deck is one of the most commonly used. B-Deck is named based on its profile, with the letter “B” denoting its shape.

B-Deck standard profile comes with 1.5” deep and 36’’ cover width. In practice, B Decking is the ideal solution for short to medium span applications that span 10 feet maximum.

Read more: B-deck roll forming machine

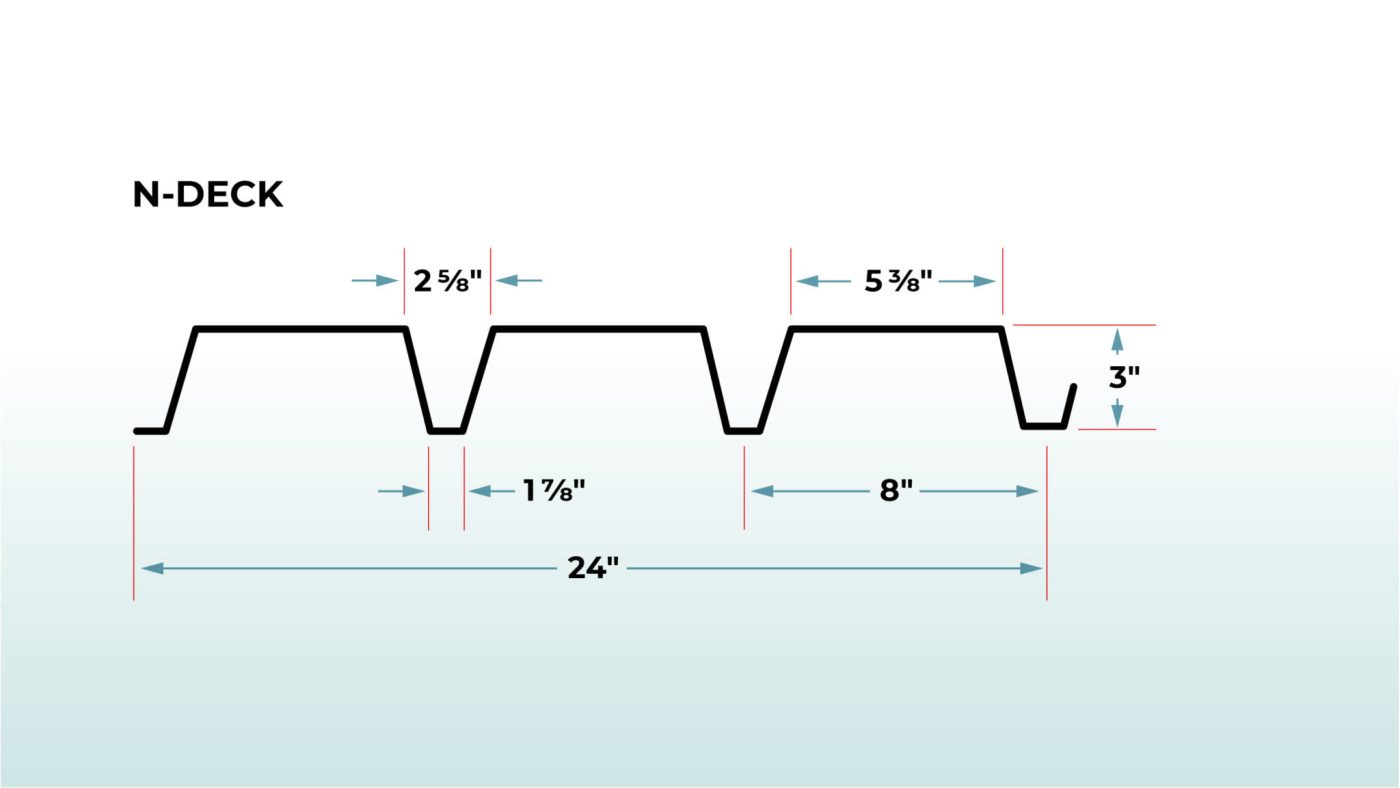

N-Deck

N Deck is a long span, 3’’ deep and 24’’ cover width metal deck. Due to its deeper grooves and better strength compared to B Deck, N Deck is a go-to choice for roofs with a span exceeding 10 feet.

B-deck and N-deck profiles

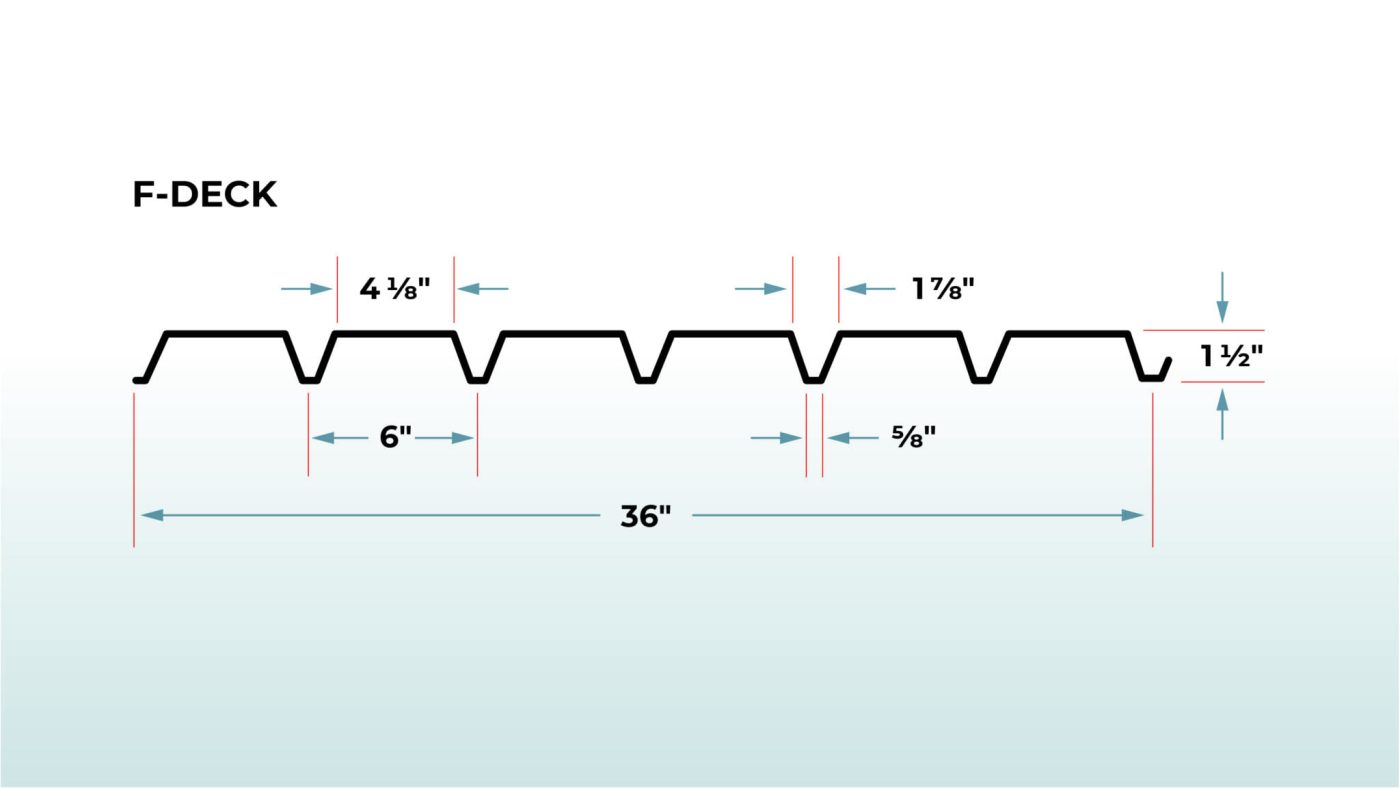

F-Deck

F Deck is a basic type of metal roof decking with a profile 1.5” deep and 36” wide. It is only recommended for repairing or replacing old roofs.

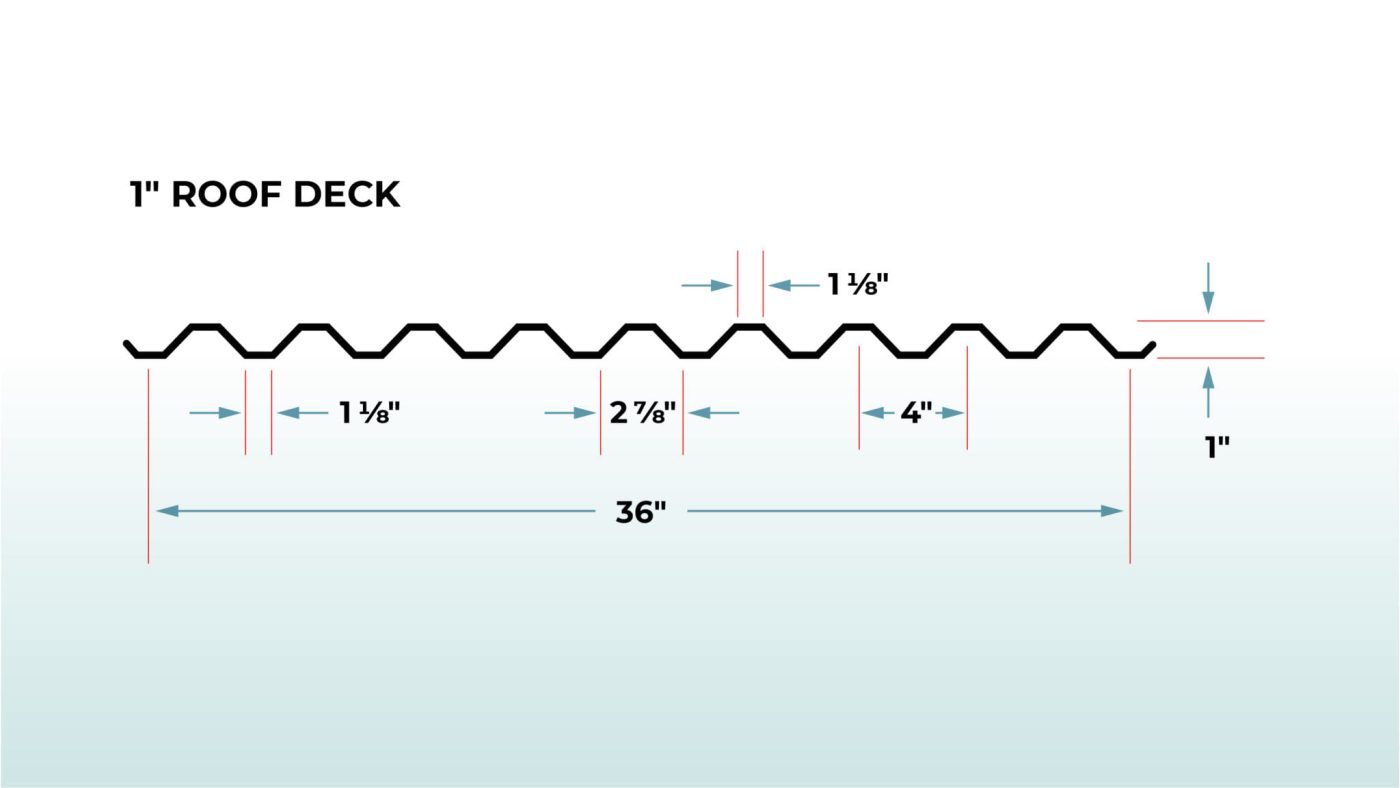

1’’ Roof Deck

With its 1-inch deep ribs, 1″ Roof Deck is a reliable roof deck. While it shares common uses with N Deck, it’s better suited for short to medium distances instead of longer spans.

F-deck and 1-inch roof deck profiles

2.2 Floor Deck

Floor deck is also known as a composite deck, because it is used together with concrete to establish a durable foundation for building structures.

The combination of floor deck and concrete provides long-lasting form and extra strength for the construction.

Typically, metal floor decks come in three types: 1.5″ Composite Deck, 2″ Composite Deck, and 3″ Composite Deck.

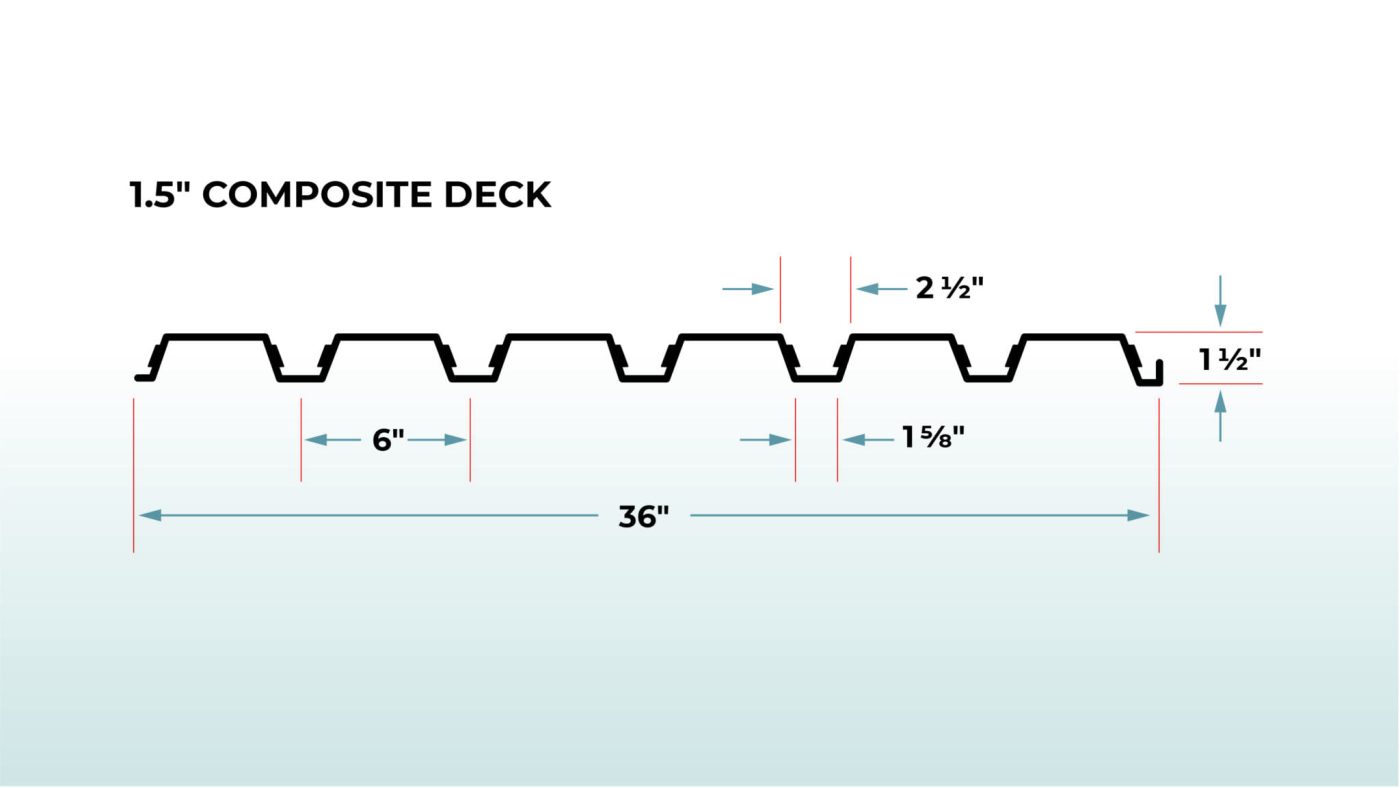

1.5 Inch Composite Deck

1.5’’ composite deck is the lowest profile type. It is best used for short spans with durable and easy-to-install features.

Combination of floor deck sheet and concrete (left) – 1.5’’ composite deck profile (right)

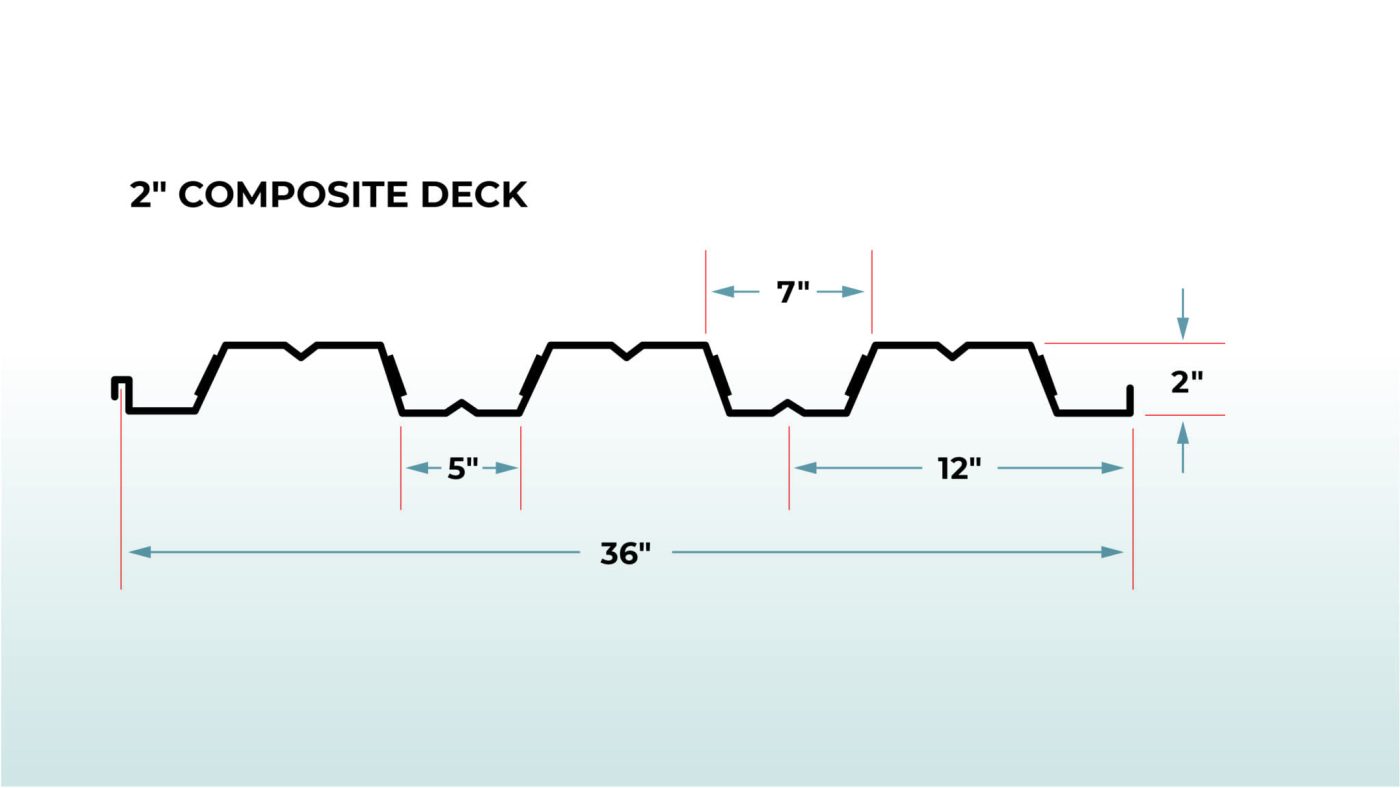

2 Inch Composite Deck

A 2-inch composite deck is capable of supporting thicker concrete slabs than a 1.5-inch deck. It is frequently used for longer structural spans.

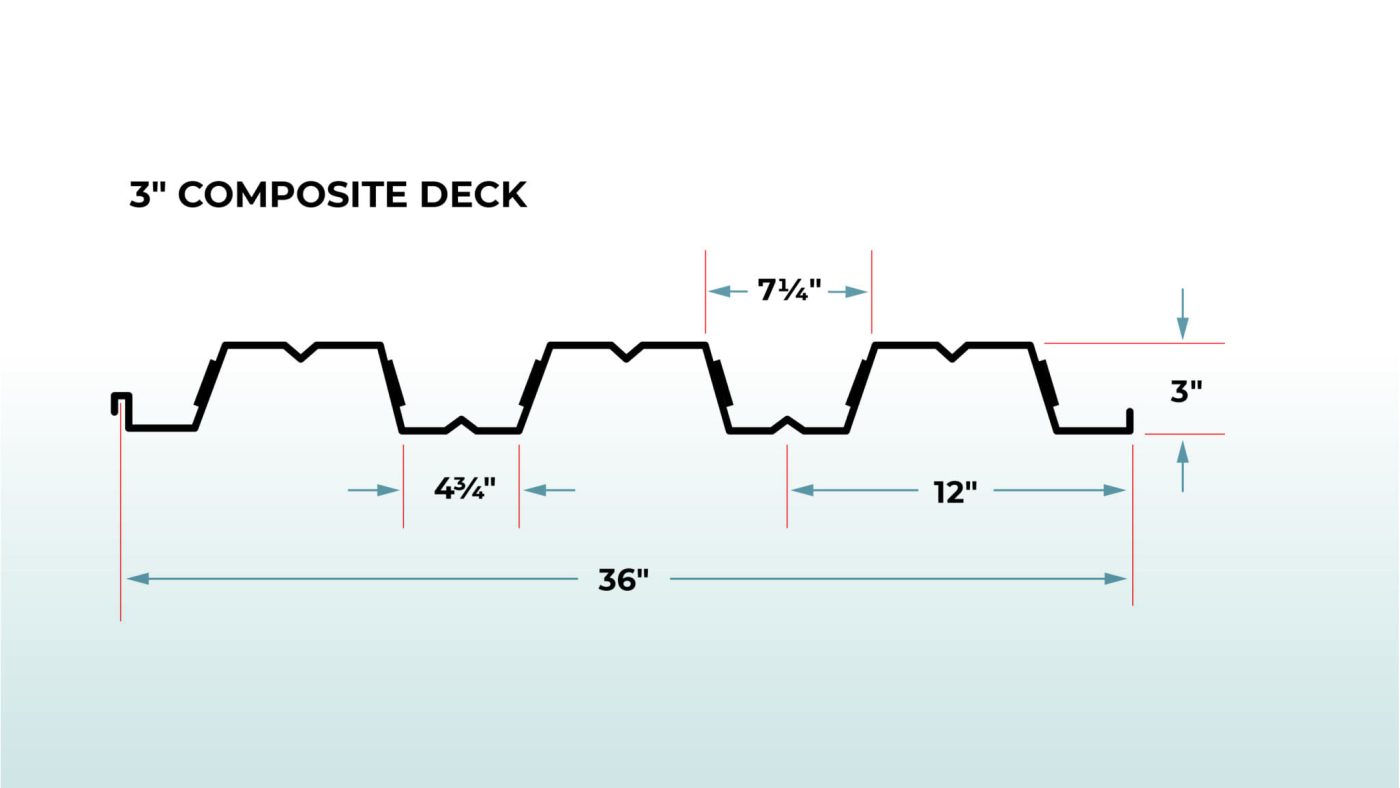

3 Inch Composite Deck

The 3-inch composite metal deck is the thickest floor deck and can hold heavier concrete than 1.5 or 2-inch decks. It’s typically chosen for long-span outdoor flooring projects.

2’’ and 3’’ composite deck profile

Read more: Floordeck roll forming machine

3. Key difference between metal roof deck and floor deck

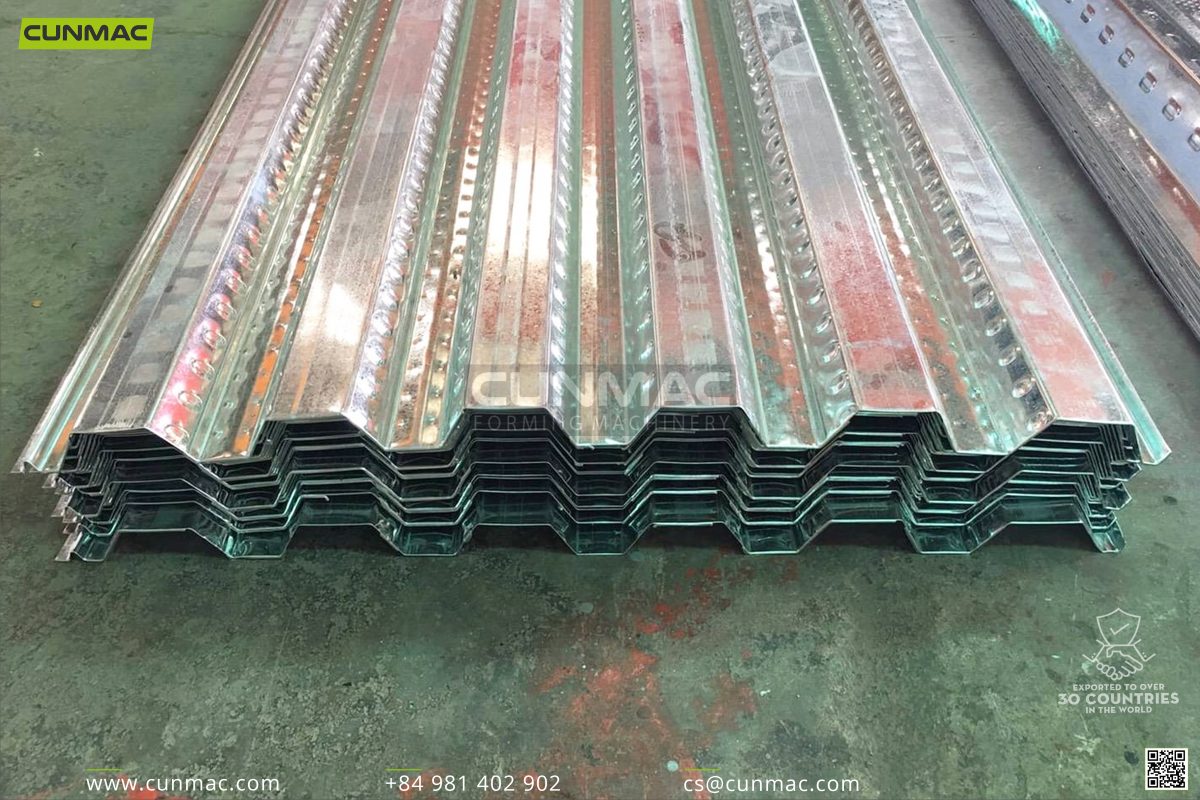

While profiles and dimensions may appear similar, the primary difference between roof decking and floor decking lies in the embossment patterns:

- Floor deck features a distinct embossment pattern that binds with poured concrete, creating a composite foundation.

- Roof deck, smooth without embossment, supports roofing system elements like insulation and built-up roofing.

B roof deck (left) and floordeck with embossment (right)

Read more: Delivery a set of B-deck roll forming machine to USA

4. Decking roll forming machine of CUNMAC

CUNMAC Vietnam has provided a range of decking roll forming machines that produce metal deck profiles include:

- B-deck roll forming machine

- N-deck roll forming machine

- Floor deck roll forming machine

B-deck roll forming machine – CUNMAC Vietnam

Floordeck roll forming machines – CUNMAC Vietnam

These machines with main advantages:

– Quality machine with reasonable price

– Installation, commissioning & training

– 24/7 after-sales service – Warranty 24 months

– Quality materials for rollers and blades from SKD11 Japan, S45C Taiwan, components from Japan (Hitachi/Toshiba/Mitsubishi), Germany (Siemens), Taiwan (Teco, Delta, Yuken)

– Meet specific requirements of customers such as: machine drawing and profile measurement in inch…

5. About CUNMAC Machinery

CUNMAC Vietnam, an innovative engineering machine manufacturer (OEM), to customize design and provide solutions for roll forming machines to over 30 countries in the world.

CUNMAC products are delivered across many markets such as America, France, Italy, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, Vietnam, etc.

CUNMAC Machinery has a wide range of roll formers, including:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.

If you are ready to get more information please contact our consultants today, we would be really happy to assist you.