C Studs and U Tracks

C studs are the vertical framing components, while U tracks form the horizontal framework in partition systems, both commonly used with multiple layers of gypsum board or for lightweight structure.

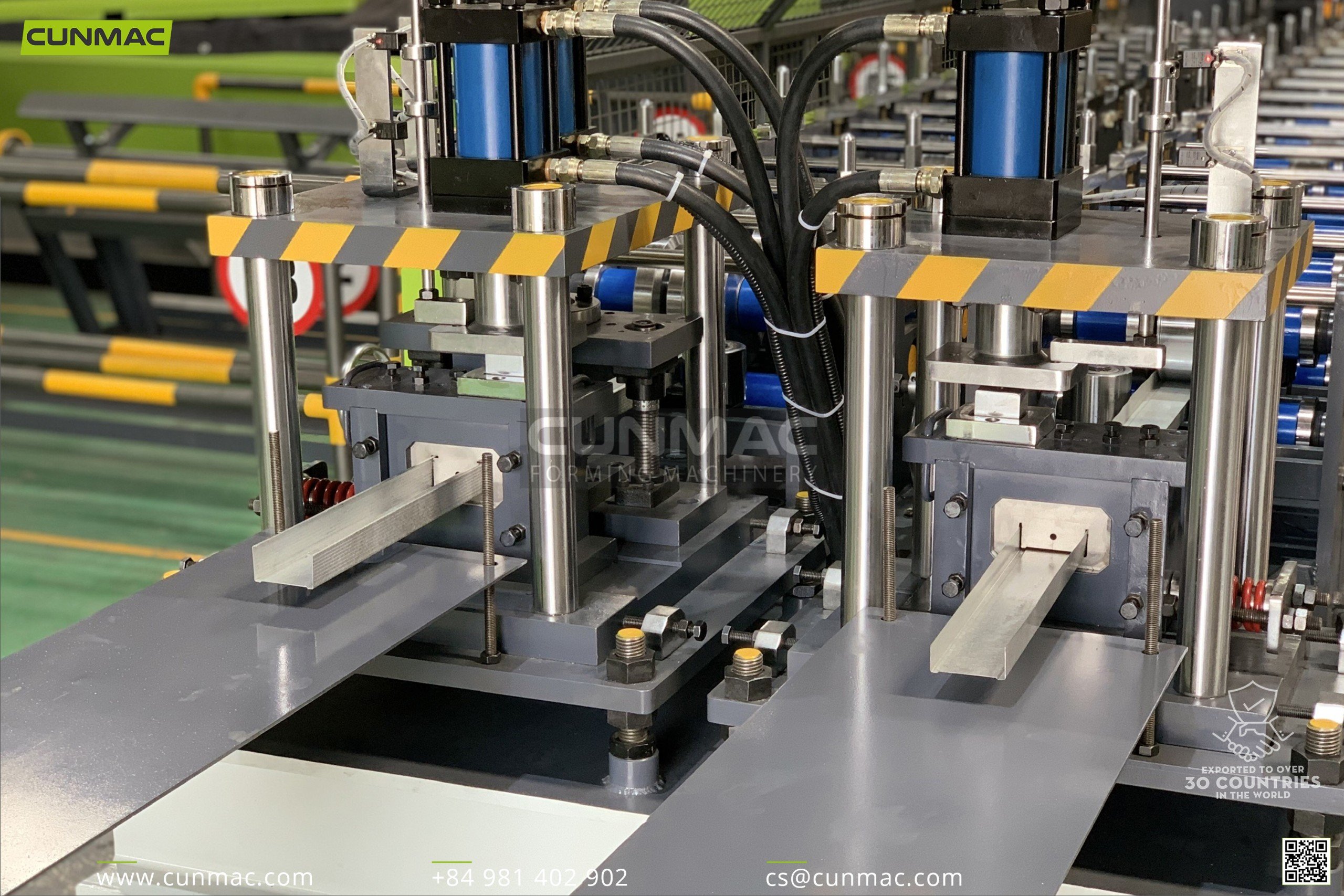

Combined stud track making machine

Read more: Combined roll forming machine

The stud track making machine manufactured by CUNMAC is a worth considering choice for factories mainly focused on producing lightweight frame sections. CUNMAC combined stud track machine comes equipped with:

- 2 sets of manual/semi-auto decoiler 2 tons

- 2 sets of manual run-out table 4 – 6 meters

- Optional safety cover for enhanced protection

C studs and U tracks in drywall framing system

Read more: Single C stud and U track roll forming machine

Combined Stud and Track Roll Forming Machine

The combined stud track roll forming machine is an innovative solution designed to efficiently produce metal framing components: C studs and U tracks. This versatile machine integrates two separate roll forming processes into a single unit, offering an optimized, space-saving approach to manufacturing both C studs and U tracks, which are essential for lightweight, durable, and cost-effective wall and ceiling applications.

Combined stud track roll forming machine – CUNMAC Vietnam

Machine video

Are you interested in this product? Fill out the form below to get all the details!

[contact-form-7 id=”33059″]SPECIFICATIONS & EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

| SPECIFICATIONS | |

| Total power | 5.5 – 7.5kW |

| Speed | 16 – 30m/min |

| Dimension (LxWxH) | (6-8)x(1.2-1.4)x1.4m |

| Weight of machine | 5 – 7 tons |

| Station quantity | 12 – 16 |

| Thickness of material | 0.5 – 1.0mm (G300-G550) |

| Material width | 100 – 300mm |

| Transmission system | Hydraulic motor |

| Cutting system | Hydraulic cylinder (front cutting) |

| Control system | Automatic with PLC, HMI, Inverter |

| EQUIPMENT | |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | SCHNEIDER (France) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

ABOUT CUNMAC MACHINERY

CUNMAC products are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

We offer a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.