What is tile roofing roll forming machine?

Tile roofing roll forming machine or roof tile making machine is a machine can make tile roofing sheets by forming metal sheet. Step by step, the rollers inside machine will shape metal sheet and pressing system make it become a tile roofing sheet. For ease of understanding, you can see the video Tile roofing roll forming machine on Youtube. Click here

The machine is fully automatic and it is easy to operate with friendly HMI panel. It consists of one decoiler, sheet guiding equipment, roll forming section, PLC control system, Hydraulic cutting, collection table.

Their main advantages are beautifully customized designs, easy and stable operation with strong body frame.

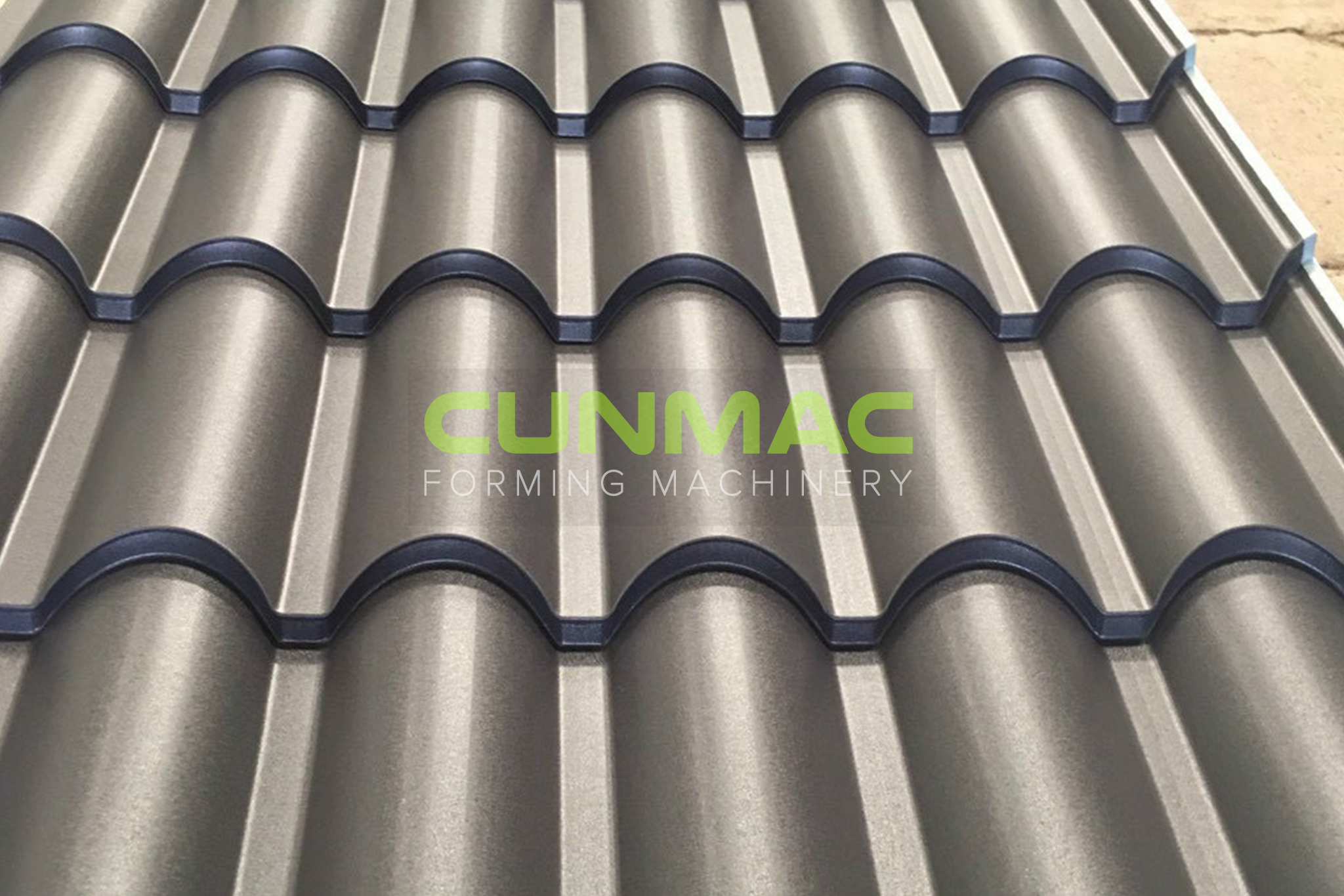

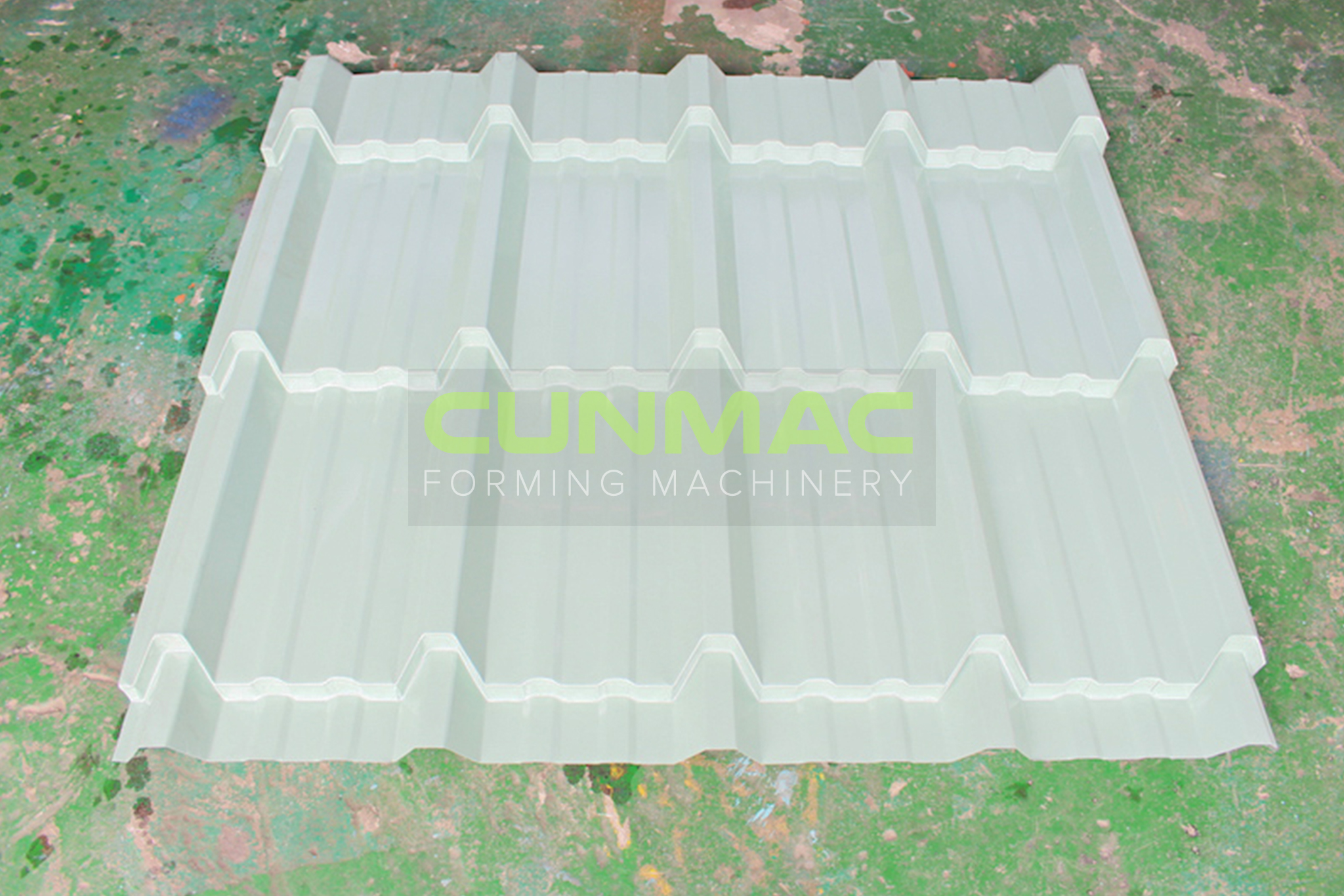

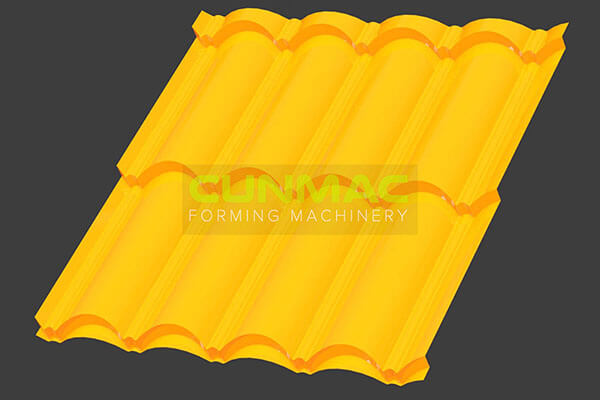

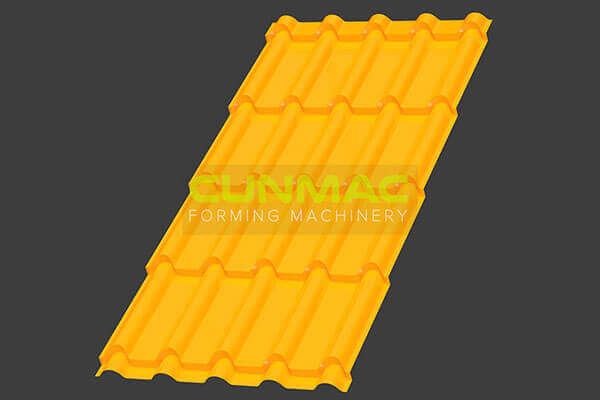

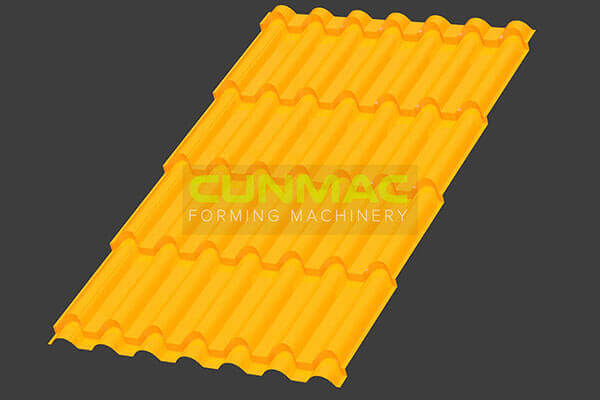

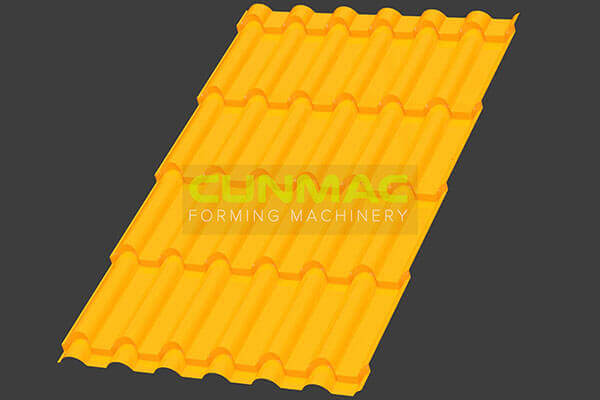

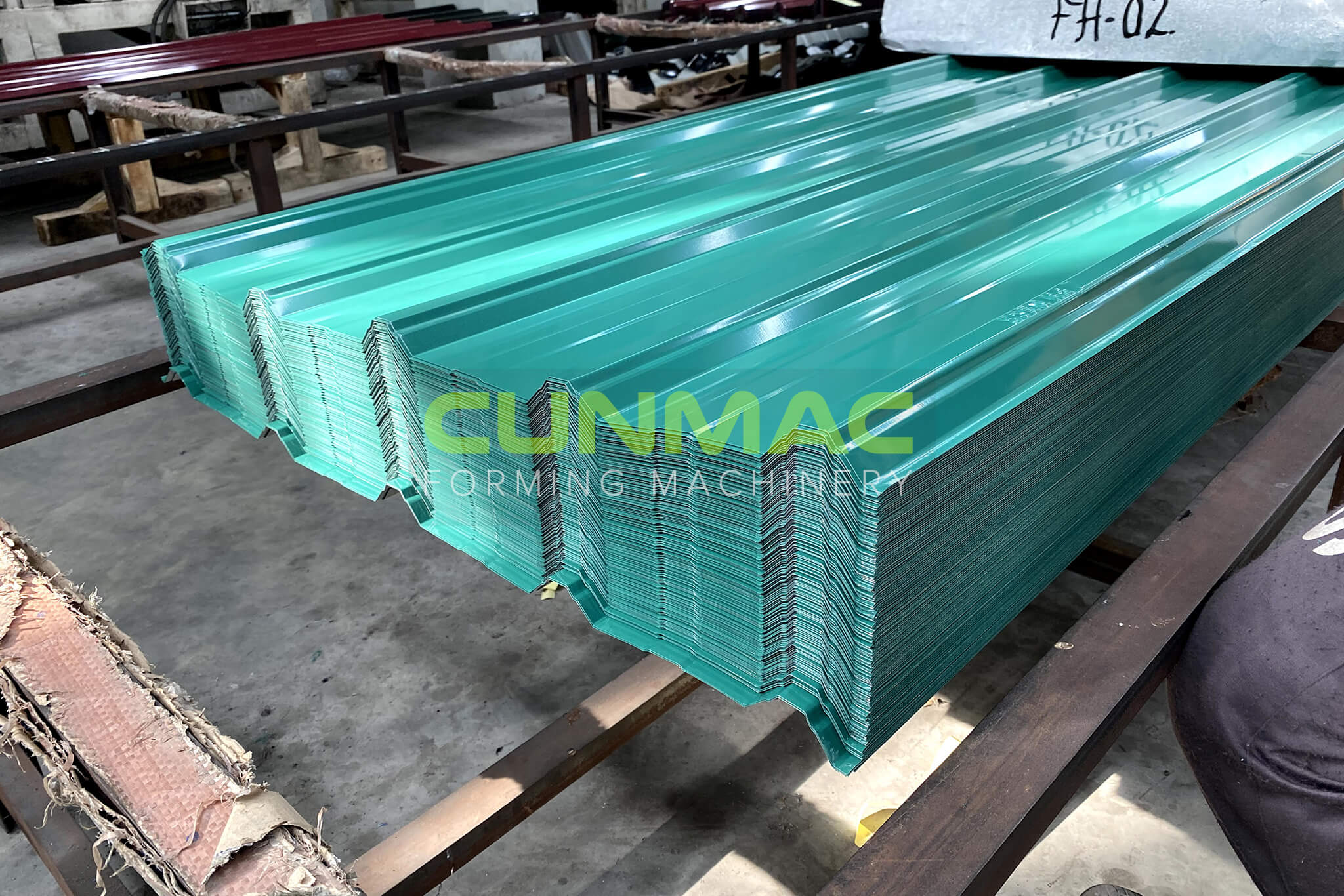

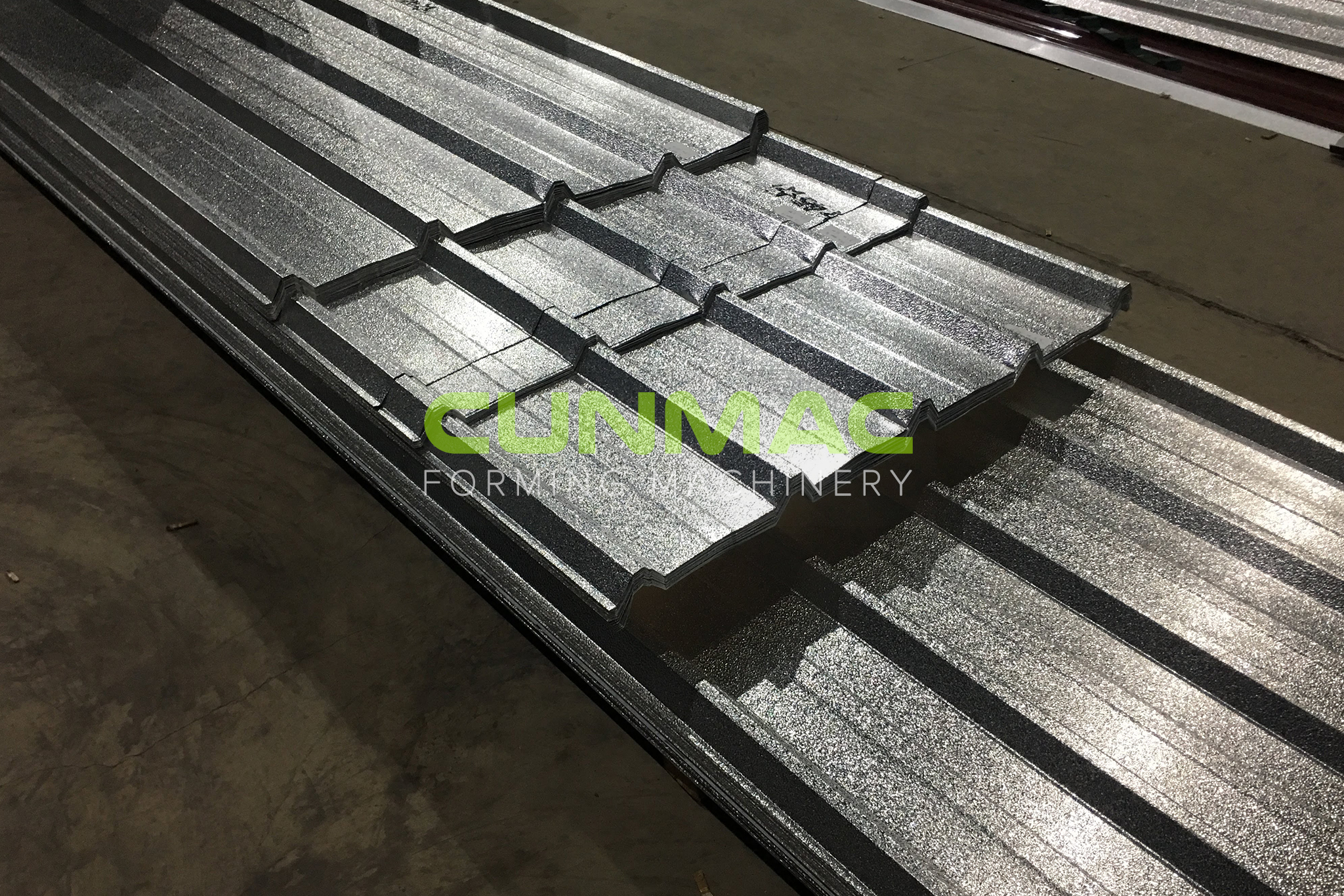

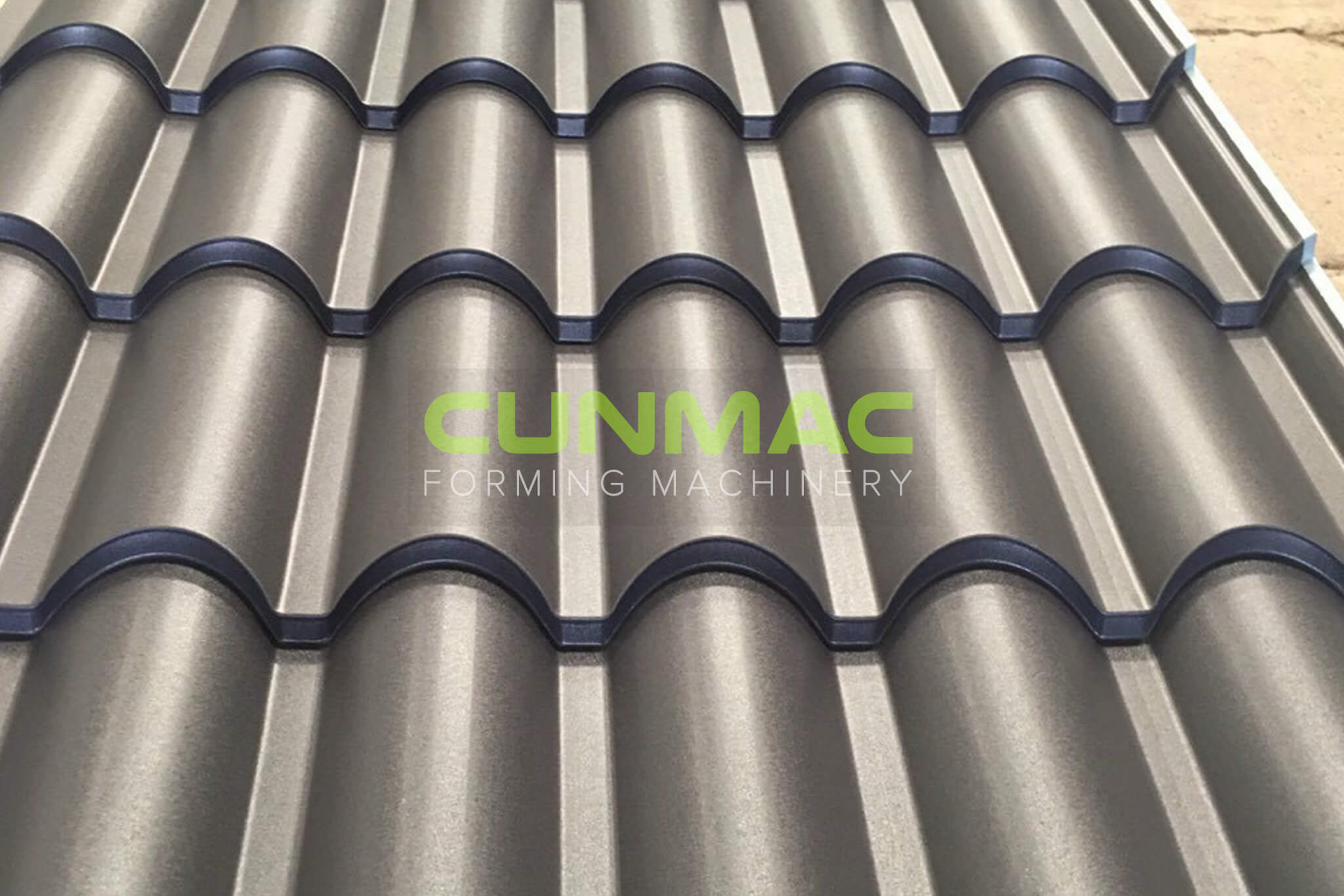

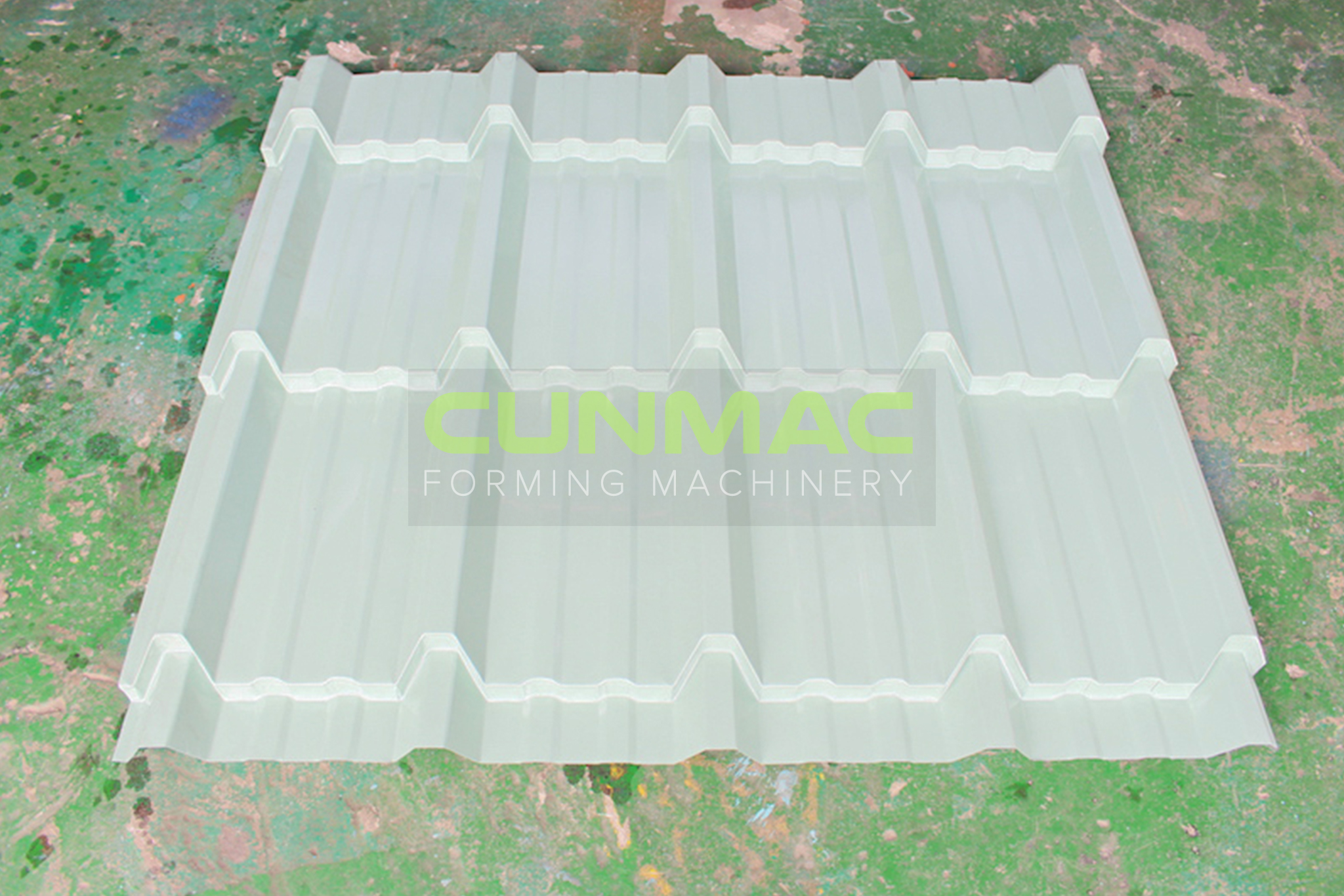

Glazed Tile Roll Forming Machine has many profiles: Classic tile, Master tile, Ruby tile, Roman tile, Nosen tile, Wood tile, Nuou tile, Aspirant tile, PVDF tile, Modern tile, Nopad tile, wave tile (concave), paragon tile, excellent tile, universe tile, hoduras tile

At CUNMAC, we offer tile roofing roll forming machines that can form a wide range of roofing tile wave profiles to meet diverse market demands.

Advanced Design for Precision Tile Roofing Production

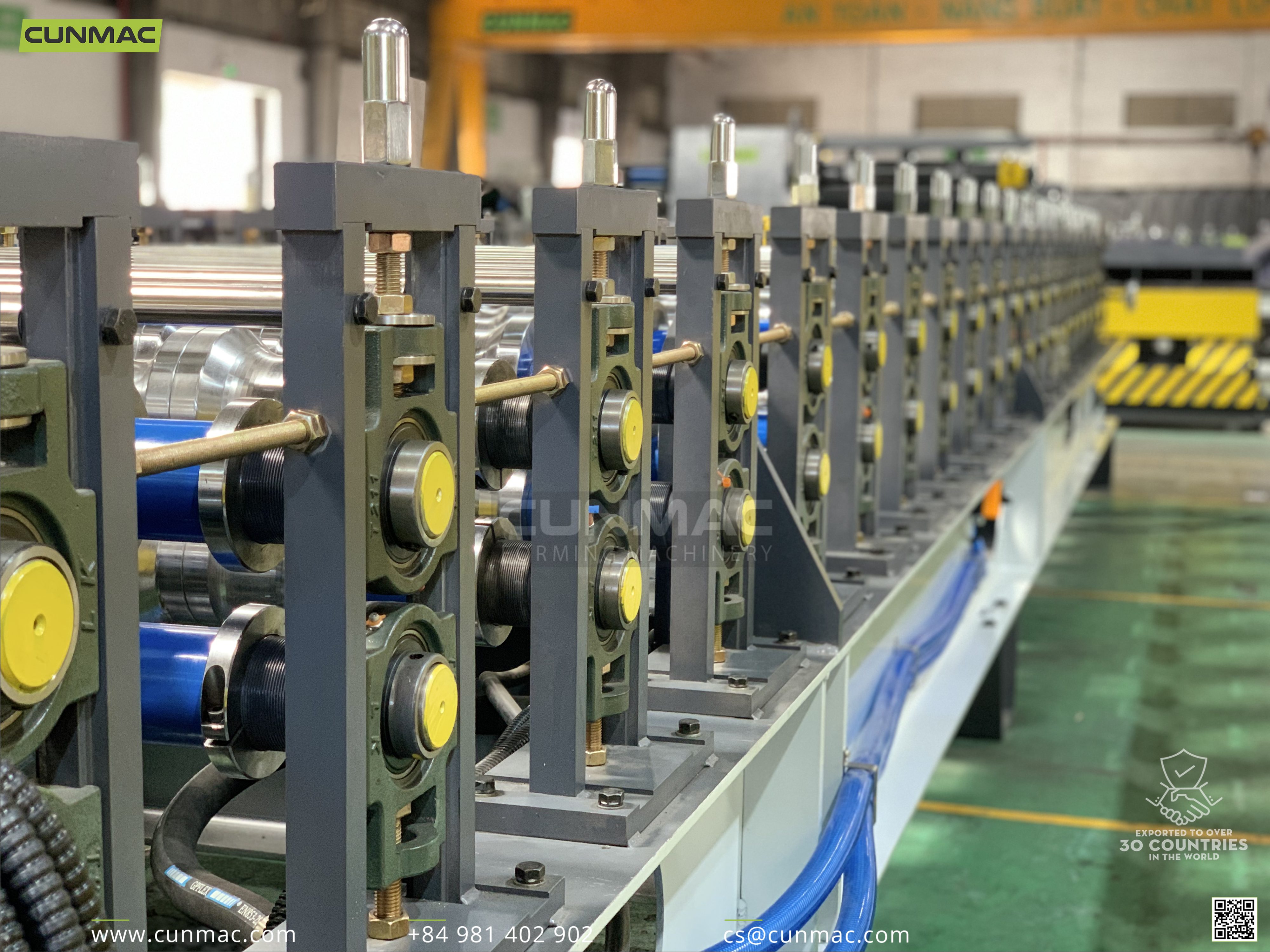

The Tile Roofing Roll Forming Machine is built on a reinforced heavy-duty frame that ensures excellent rigidity and vibration resistance during continuous operation. This advanced structural design allows the machine to maintain consistent forming accuracy even at high speed, making it a reliable high speed machine for industrial roofing production

The roll forming section uses large-diameter solid shafts and precision-machined rollers manufactured from high-grade alloy steel. These components ensure smooth material flow, uniform tile curvature, and superior surface quality, which are critical for producing high-end glazed roof tiles, stepped tiles, and ag classic rib roof tiles.

To enhance long-term reliability, the system is equipped with high-quality, industrial-grade bearings, ensuring smooth rotation, reduced friction, and lower maintenance requirements over extended production cycles

High-Speed Performance with Intelligent Control

This tile roofing roll forming machine is powered by a robust motor and industrial-grade gearbox to provide stable torque and consistent forming speed. For advanced configurations, a servo-driven system can be integrated to achieve more precise speed control, improved energy efficiency, and smoother operation

The intelligent PLC control system with touchscreen HMI allows operators to easily set product length, manage production parameters, and monitor machine status in real time. This automation capability positions the system among the top tile roll forming machine choices for manufacturers seeking both productivity and precision

Accurate Cutting and Industrial Material Handling

The machine adopts a high-precision hydraulic cutting system using SKD11 cutting blades, delivering clean, accurate cuts without damaging tile profiles. All cutting operations are synchronized with the forming process to ensure consistent length and high efficiency.

For industrial-scale production, the system can be equipped with a 6-ton hydraulic decoiler combined with a coil car, allowing fast, safe coil loading and significantly reducing downtime. This configuration makes the machine ideal for OEM tile roll forming machine projects and large-volume manufacturing.

WHY CHOOSE THIS TILE ROOFING ROLL FORMING MACHINE?

Reinforced heavy-duty frame

Ensures excellent machine stability, reduced vibration, and long service life during continuous high-speed operation

High-precision roll forming system

Delivers accurate and consistent tile profiles for classic tile, master tile, prima tile, glazed tile, and stepped tile designs

Heavy-duty bearings

Provide smooth rotation, strong load capacity, and lower maintenance cost over long-term production

High speed machine capability

Supports efficient mass production while maintaining stable quality and forming accuracy

Advanced PLC & HMI automation

Simplifies operation, improves production accuracy, and ensures repeatable output for every roofing tile

MACHINE VIDEO

Is an Tile Roofing Roll Foming Machine a solution you are looking for?

Talk to our expert now!

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, Servo, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 11 – 15kw | 15 – 18kw | |

| Speed | 4 – 6m/min | 7 – 10m/min | |

| Dimension (LxWxH) | (8-11)x(1.6-2.2)x1.8m | (9-12)x(1.6-2.2)x1.8m | |

| Weight of machine | 9 – 12 tons | 10 – 14 tons | |

| Roller station | 12 – 20 | 12 – 20 | |

| Material thickness | 0.15 – 0.5mm (G300-G550) | 0.15 – 0.5mm (G300-G550) | |

| Material width | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm | |

| Transmission system | Hydraulic motor | Servo motor with gear box | |

| Cutting system | Hydraulic cylinder (rear & front cutting) | Hydraulic cylinder (rear & front cutting) | |

| Control system | Automatic with PLC, HMI, Inverter | Automatic with PLC, HMI, Servo | |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Proface (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

Cunmac proudly provides Tile roofing roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.