Discover how CUNMAC’s AG Panel Roll Forming Machine delivers precision, speed, and versatility to meet growing global demand for durable, wide-coverage metal roofing panels.

Why manufacturers choose AG panel roll forming machine?

Meeting the Evolving Needs of Modern Roofing Manufacturers

In today’s construction market, the demand for high-durability, wide-coverage roofing panels continues to rise – especially across industrial, agricultural, and residential projects. Builders are seeking roofing systems that ensure long-lasting protection, easy installation, and visual uniformity.

At the same time, roofing manufacturers face growing challenges: tight delivery deadlines, fluctuating material costs, and the constant need to maintain consistent quality across large production volumes.

The AG Panel Roll Forming Machine from CUNMAC was developed precisely to address these challenges. With advanced forming technology, computer-controlled precision, and a robust mechanical structure, it enables manufacturers to achieve high-speed, high-accuracy, and high-consistency sheet forming – ensuring every panel meets today’s demanding roofing standards.

Double-layer Roofing Roll Forming Machine line operating at high speed

Read more: Double-layer roofing roll forming machine

Precision Forming Technology for Superior Quality

Every sheet produced by the AG Panel line reflects engineering excellence.

Using CNC-machined forming rollers, the system guarantees consistent rib height, symmetrical profiles, and flawless interlocks. This precision not only enhances the structural integrity of the roofing panels but also ensures perfect alignment during installation.

The heavy-duty frame minimizes vibration and material stress, while automated adjustment systems maintain consistent panel dimensions – ensuring the final product meets strict architectural and industrial standards.

Roofing Roll Forming Machine

Read more: Roofing Roll Forming Machine

Full Automation – Speed and Stability in Every Cycle

The AG Panel Roll Forming Machine integrates complete automation – from decoiling, leveling, and roll forming to cutting and stacking. The operator controls the entire process via a PLC interface, allowing quick changes to panel length, quantity, and line speed.

With a maximum production speed of 50-60 meters per minute, the AG Panel line helps manufacturers accelerate output, reduce manpower, and meet urgent delivery requirements with ease.

AG panels produced by CUNMAC machine

Read more: AG Panel Roll Forming Machine

Applications & Market Demand

Versatility for Different Roofing Projects

AG Panel sheets are widely used across residential, commercial, industrial, and agricultural projects. Their design provides superior water resistance, structural strength, and aesthetic uniformity, making them a preferred choice in modern construction.

Diverse applications of AG panel for roofing

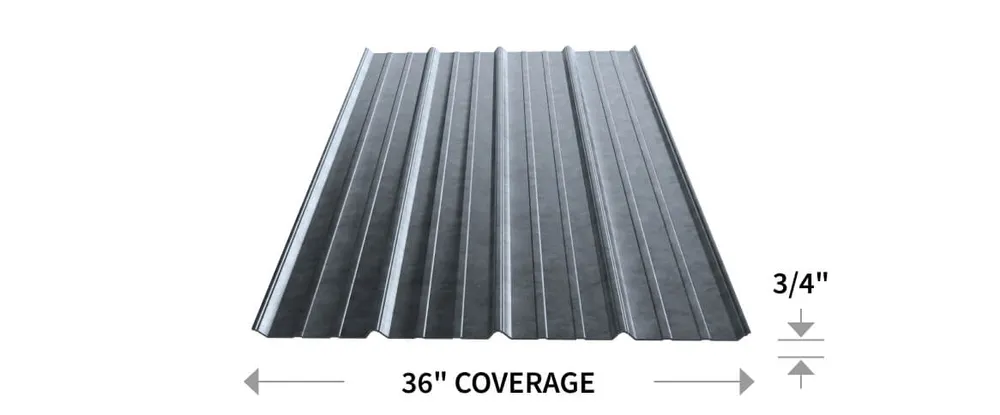

One of the most widely used roofing configurations in the market is the 36-inch coverage profile – favored for its efficient material usage and installation simplicity.

The CUNMAC AG Panel Roll Forming Machine can be customized to produce 36’’ coverage roofing panels, along with various other standard or custom profiles.

This flexibility allows manufacturers to expand their product range without investing in multiple machines, helping them adapt to different regional and market requirements quickly.

36-inch coverage roofing sheets produced by AG Panel Roll Forming Machine

Engineering Excellence and Longevity

Every detail of the AG Panel Roll Forming Machine reflects CUNMAC’s engineering craftsmanship.

The forming stations are manufactured from hardened alloy steel for maximum durability and are chrome-coated to ensure smooth material flow and extended roller life.

The cutting system, driven by a hydraulic or servo motor, provides clean, burr-free cuts synchronized perfectly with the forming speed.

Each forming unit is precisely aligned to reduce friction and eliminate sheet deformation – ensuring perfect edges and panel flatness over years of continuous operation.

Read more: Slitting and cutting to length machine

Productivity and Cost Efficiency

The machine is designed for maximum uptime with automatic length measurement, fast profile changeovers, and low maintenance requirements.

Manufacturers can achieve up to 20% higher productivity while reducing scrap and energy consumption.

When paired with an automatic stacking system, the AG Panel line becomes a seamless production solution – cutting, stacking, and counting panels automatically, minimizing handling time.

AG Panel Roll Forming Machine

Global Standard Manufacturing & Quality Assurance

All CUNMAC machines are built under international quality and safety standards. Each AG Panel line undergoes comprehensive testing before shipment to guarantee performance stability in demanding environments.

Key electrical components come from Siemens, Delta, and Schneider, ensuring reliable operation and easy spare part availability worldwide.

Partnering with CUNMAC – Your Path to Growth

CUNMAC is not just a machinery supplier – it is a trusted partner for long-term success. The company provides full support including machine installation, training, customization, and

technical assistance to help manufacturers achieve continuous productivity improvements.

CUNMAC engineer providing after-sales training to client

We, a roll forming machine manufacturer, specialize in custom designing and manufacturing a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

CUNMAC products are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

At CUNMAC, ensuring customer satisfaction stands as our highest priority. This commitment drives us to continually improve and provide exceptional products and services.

If you are looking for a roll forming machinery that guarantees superior performance, reliability, and customer satisfaction, look no further than CUNMAC.

CUNMAC is committed to delivering beyond expectations, and the successful delivery of the Crimping curve forming machine is a testament to our resolute dedication to our valued customers.

Contact our expert team today to discuss your specific requirements and experience excellence in roll forming machinery firsthand.

ABOUT CUNMAC MACHINERY

CUNMAC Co., Ltd is a leading manufacturer of cold roll forming solutions that addresses the demands of the modern construction industry. With over 15 years of experience, we have built a reputation for delivering high-quality and innovative roll forming solutions to customers in over 30 countries across the globe.

All CUNMAC machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.

Hotline: +84 981 402 902

Mail: cs@cunmac.com

Please contact our consultants today, we would be really happy to assist you.