Apa itu mesin roll forming atap dua lapis?

Cunmac dengan bangga menyediakan mesin roll forming atap dua lapis di pasar kelas atas domestik dan internasional termasuk Asia, Australia, Timur Tengah, Afrika, Amerika.

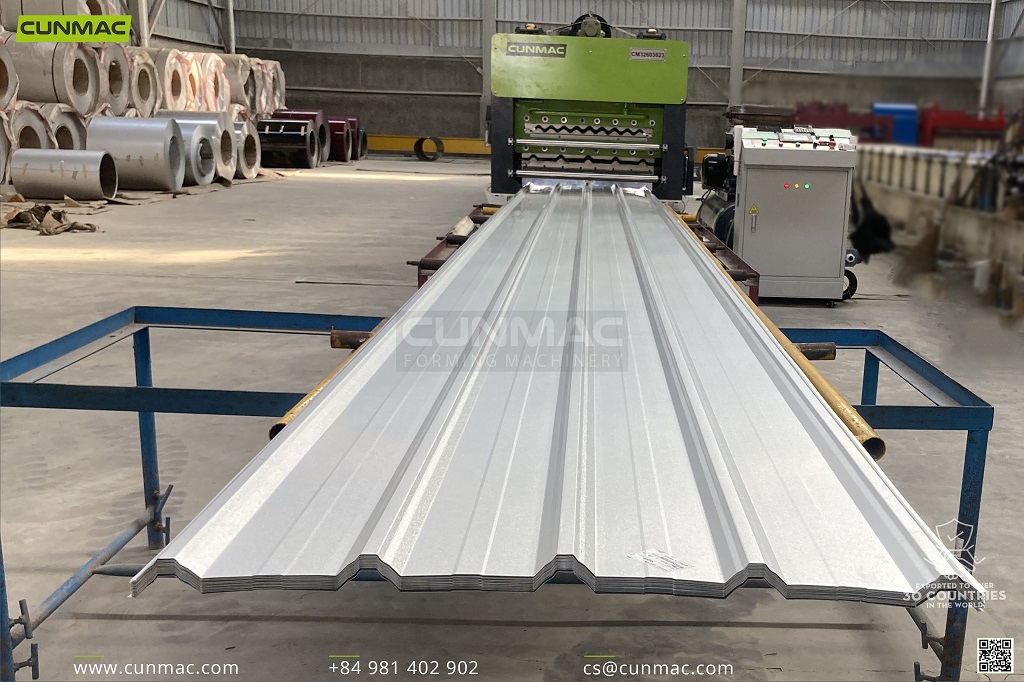

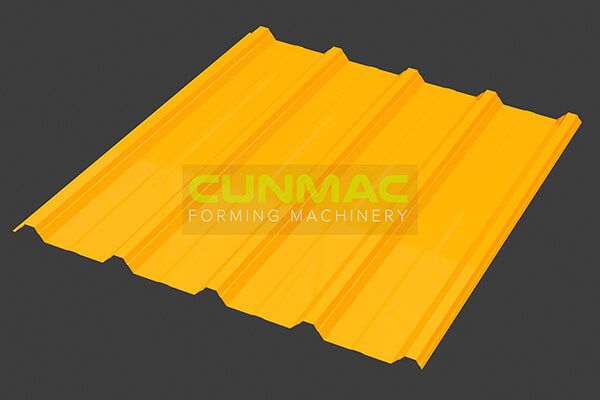

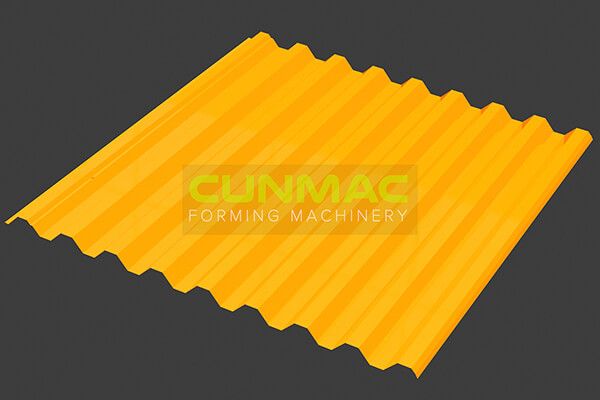

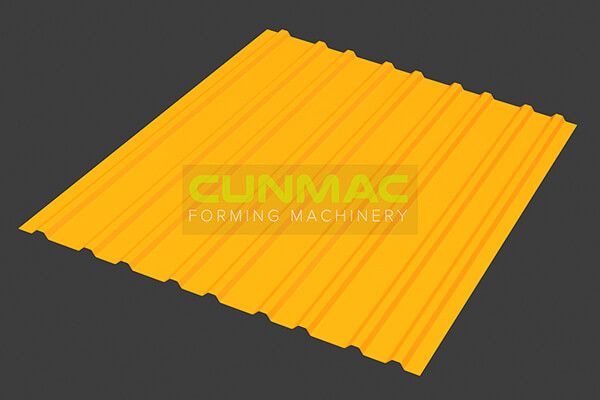

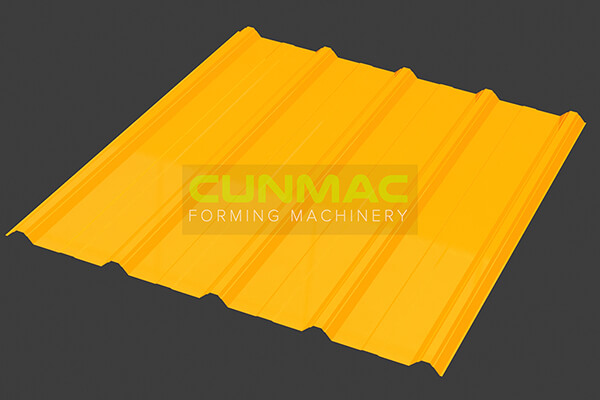

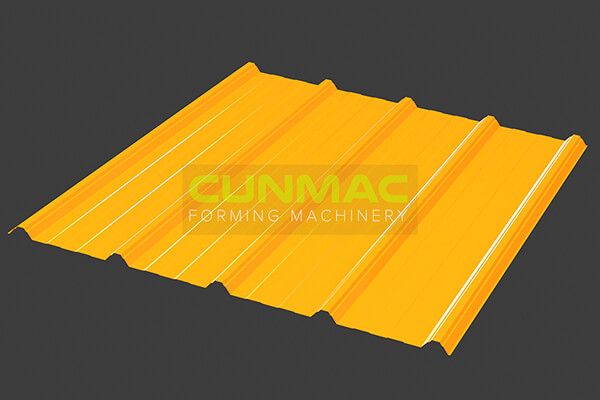

Ada berbagai profil tipe rusuk tergantung pada negaranya, termasuk 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, tetapi yang paling umum adalah profil tipe 5. Jenis atap logam untuk lapisan ganda tergantung pada produk pelanggan: Atap trapesium standar, Atap bergelombang, atau Genteng Metal.

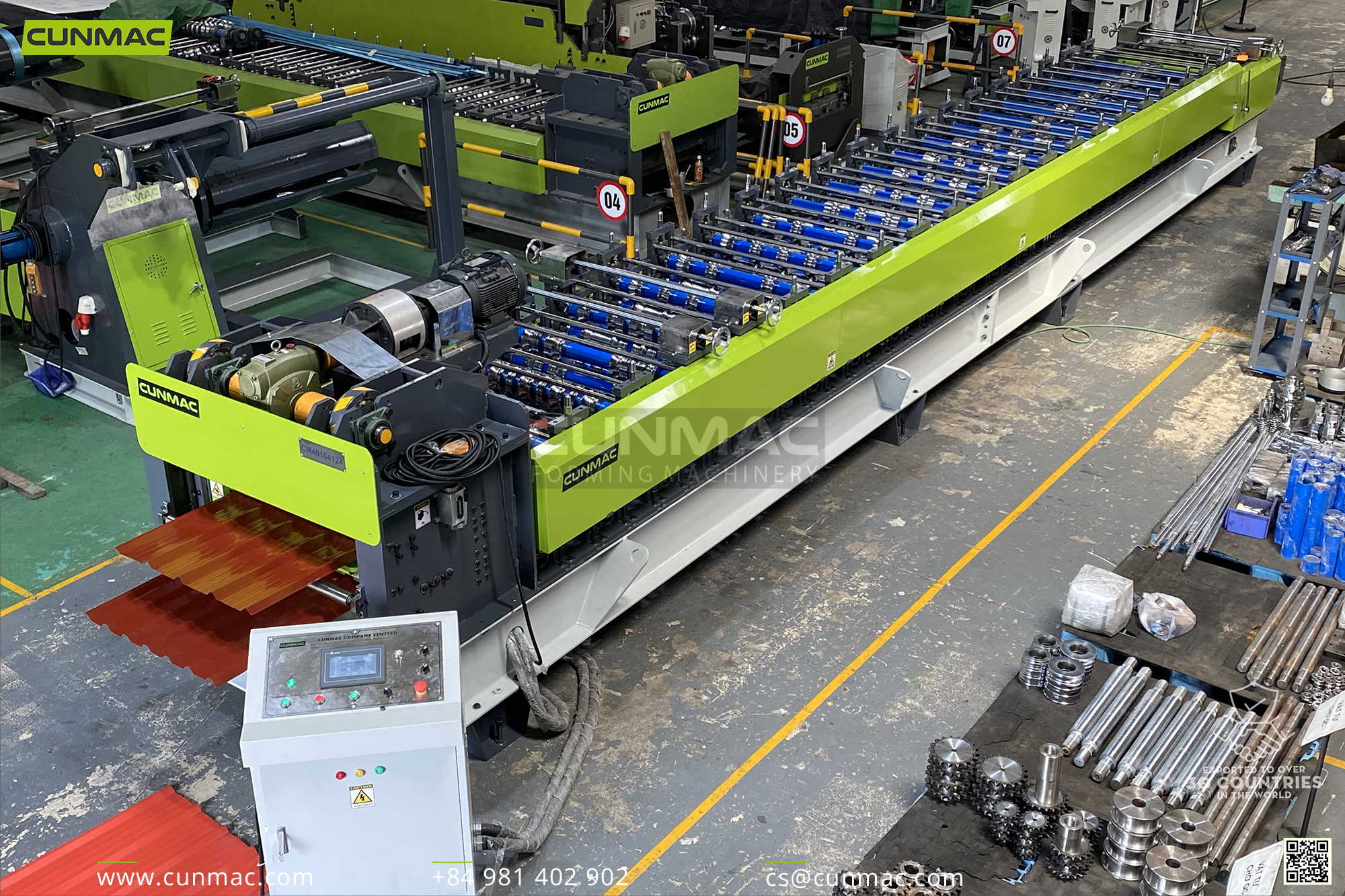

Mesin pembuat gulung lapisan ganda memiliki dua lapisan atau dua tingkat bagian pembentuk gulung yang memberinya nama lain mesin pembuat gulung tingkat ganda, dan karena mesin ini membuat dua lembaran logam dan mesin pembuat gulung lembaran ganda, Mesin Pembentuk Gulung Dek Ganda, 2 in 1 Mesin Lembaran Atap Dek Ganda juga merupakan nama yang tidak asing lagi bagi orang-orang.

Mesin lapisan ganda membuat atap lapisan ganda untuk menghemat ruang Anda, menghemat waktu Anda dan menghemat uang Anda, 2 profil dalam 1 mesin.

VIDEO MESIN

SPESIFIKASI & PERALATAN

– Roll membentuk dan memotong otomatis dengan Inverter, PLC, HMI

– Pengaturan panjang otomatis yang dapat diprogram melalui panel sentuh

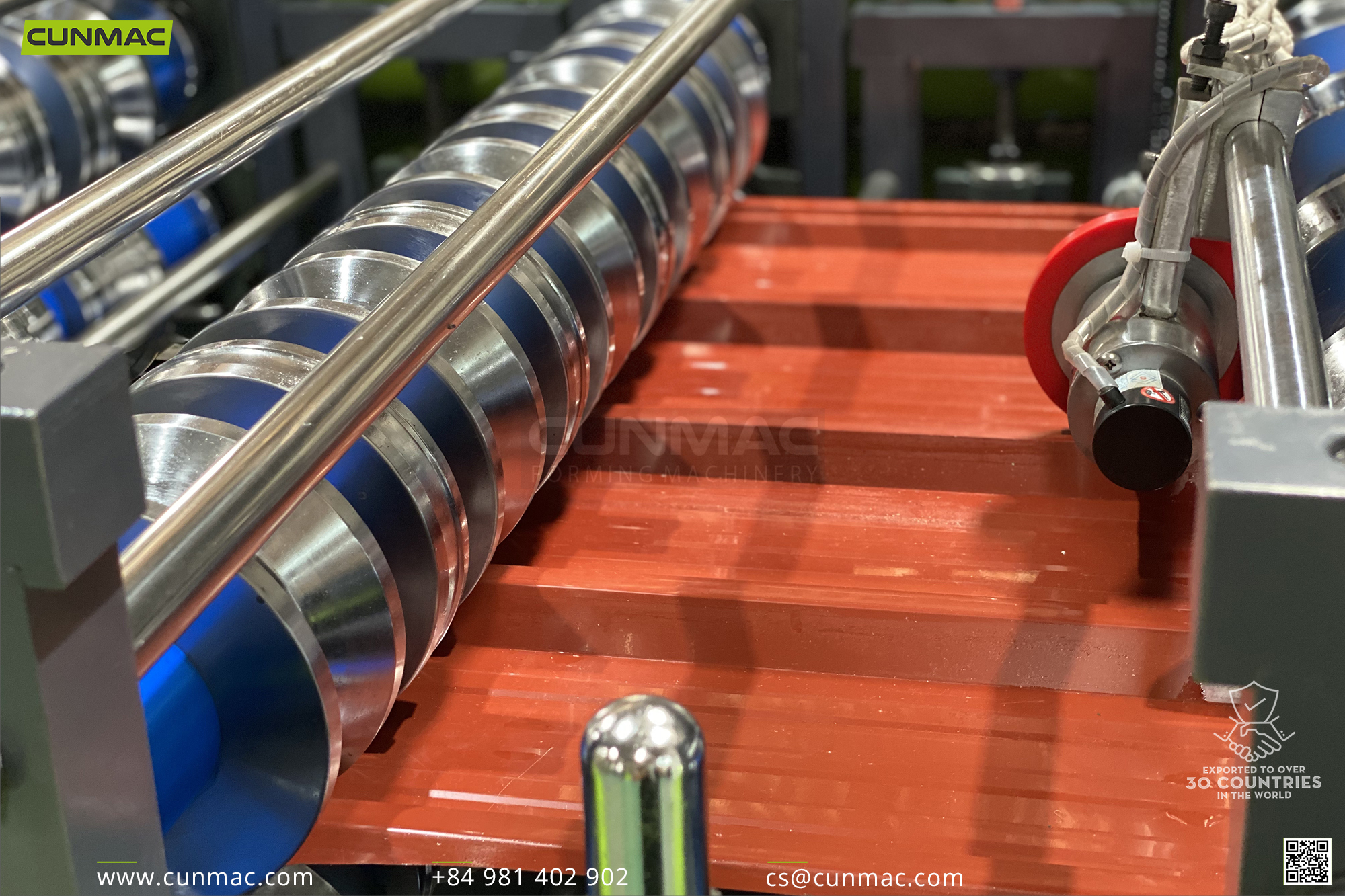

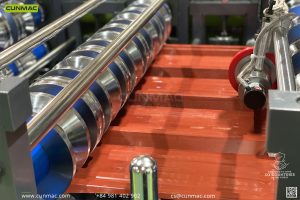

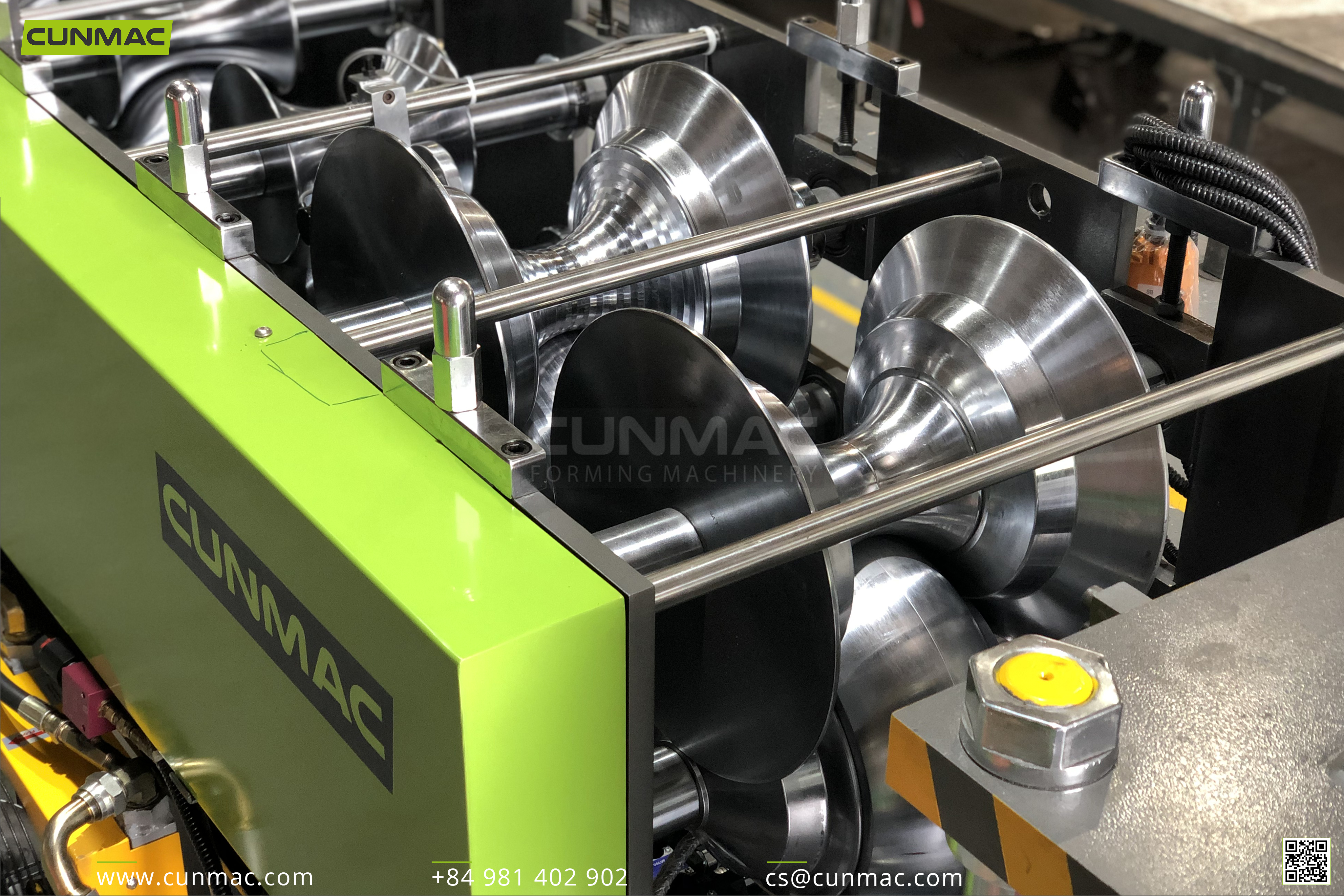

– Roller dan blade dibuat dari paduan dan baja SKD11 60-62HRC

– Komponen listrik dan hidrolik dari Jepang, Jerman

– Simpan riwayat untuk pesanan dalam 30 hari

– Sesuaikan desain

– Pengoperasian yang stabil dengan kekuatan dan rangka bodi yang kuat

| SPESIFIKASI | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 5.5 – 7.5kw | 7.5 – 11kw | 11 – 22kw |

| Speed | 16 – 18m/min | 22 – 24m/min | 44 – 46m/min |

| Dimension (LxWxH) | (9-11)x(1.6-2.2)x1.8m | (9-11)x(1.6-2.2)x1.8m | (9-11)x(1.6-2.2)x1.8m |

| Weight of machine | 6 – 8 tons | 7 – 10 tons | 9 – 12 tons |

| Roller station | 16 – 18 | 18 – 21 | 20 – 24 |

| Material thickness | 0.15 to 0.7mm (G300-G550) | 0.15 – 0.7mm (G300-G550) | 0.15 – 0.7mm (G300-G550) |

| Material width | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm |

| Transmission system | Hydraulic motor | Hydraulic motor | Electric motor with gear box |

| Cutting system | Hydraulic cylinder (front cutting) | Hydraulic cylinder (rear & front cutting) | Electric motor with gear box (rear & front cutting) |

| Control system | Automatic with PLC, HMI | Automatic with PLC, HMI, Inverter | Automatic with PLC, HMI, Inverter |

| PERALATAN | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

TENTANG MESIN CUNMAC

Mesin roll forming atap dua lapis dengan bangga dibuat di Vietnam dengan komponen bermutu tinggi yang sesuai dengan standar industri.

Tentang Mesin Cunmac

Cunmac menawarkan berbagai macam produk dan solusi yang baik untuk perusahaan yang beroperasi di industri lembaran logam, konstruksi, manufaktur. Produk kami meliputi:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

Semua mesin Cunmac dibuat secara profesional dan wajar di Vietnam, tujuan kami adalah menyediakan mesin fleksibel dengan kualitas terbaik dan desain khusus yang memberikan manfaat dan pengalaman unik bagi pelanggan.