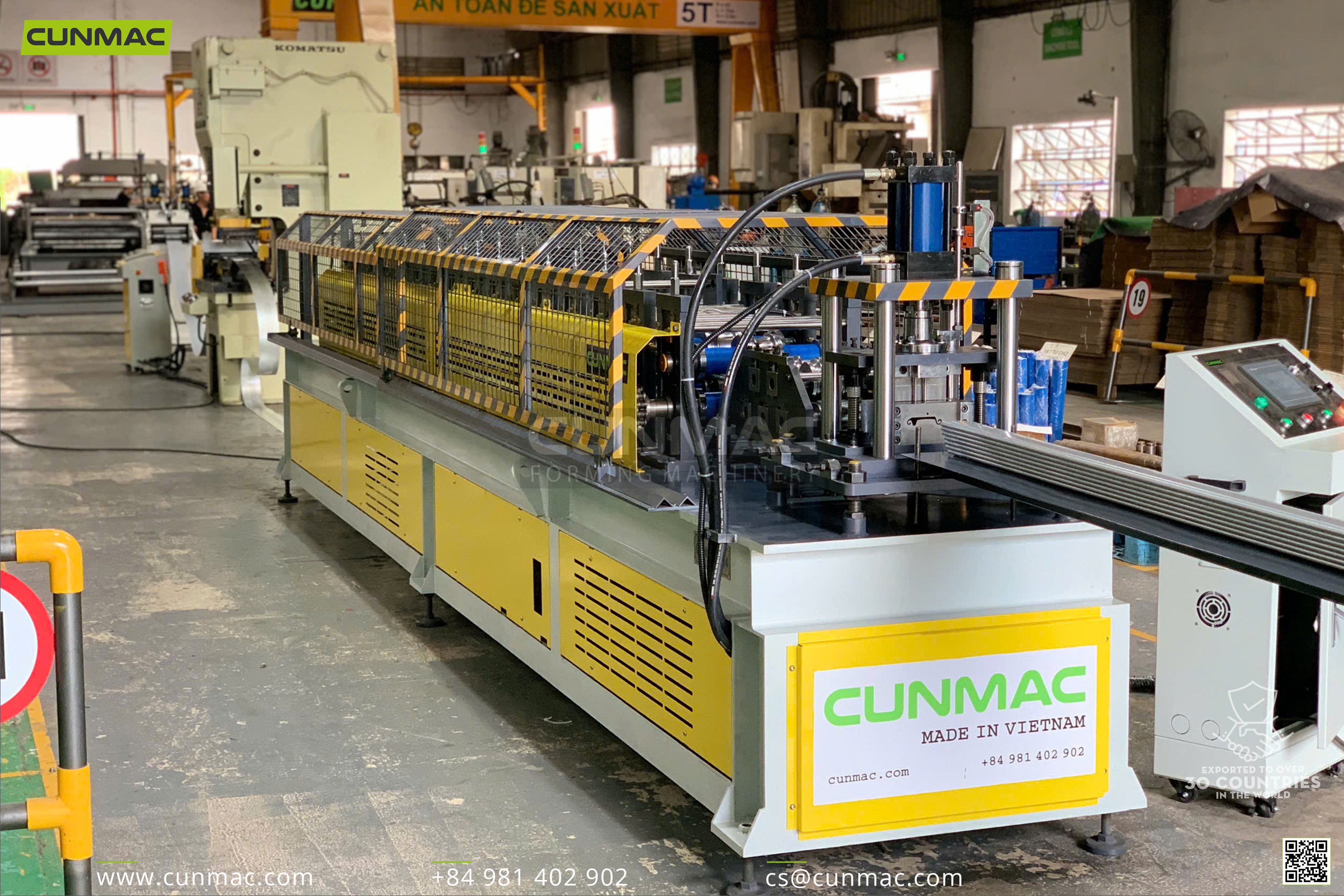

FULL AUTOMATIC PUNCHING HOLE & ROLL FORMING LINE

FOR ROOFING FRAMES AND SECTIONS

Are you struggling with manual punching that slows down production?

Do you find traditional roll forming machines inefficient and time-consuming?

Are you searching for a smarter way to produce roofing frames and purlins with precision holes?

If yes, then it’s time to discover the Full Auto Punching Hole and Roll Forming Line – an advanced solution that combines decoiling, punching, forming, and cutting into one seamless automated workflow.

The Full Auto Punching Hole and Roll Forming Line is an advanced production system designed to streamline steel processing.

By combining auto decoiling, servo feeding, high-precision punching, roll forming, and hydraulic cutting into one continuous workflow, it allows manufacturers to produce roofing frames and purlins with high speed and accuracy.

This makes it a perfect upgrade for manufacturers seeking efficiency, consistency, and long-term cost savings.

Read more: C purlin roll forming machine with punching

WHY CHOOSE THE FULL AUTO PUNCHING AND ROLL FORMING LINE?

Is an electric roofing machine a solution you are looking for?

Talk to our expert now!

WORKFLOW & KEY FEATURES

The Full Auto Punching Hole and Roll Forming Line follows a simple but efficient workflow:

Input material >> Decoiling >> Leveling & Feeding >> Punching >> Roll Forming >> Cutting >> Finished Product.

This seamless process ensures precision steel forming technology with high speed and minimal waste.

- Decoiler: 2 tons capacity, auto start/stop with the line, manual/auto coil expansion for tightening.

- Feeder: Servo feeder with integrated straightener for accurate coil feeding.

- Punching Machine: High precision power press, 60 tons capacity, open punch shape, single action slider.

- Roll Forming: 12 – 16 stations, up to 1.5mm thickness, line speed 3 – 5m/min.

- Cutting System: Hydraulic cutting (SKD11 blade Japan, 60 – 62 HRC).

- Control System: Siemens PLC (Germany), Delta touchscreen (Taiwan), Omron sensors (Japan).

- Machine Size & Weight: ~(18 – 20) x (1.6 – 1.8) x 2.2m; ~6.5 tons.

APPLICATIONS OF THE ROLL FORMING LINE

The versatility of this system makes it ideal for various applications, here are some for reference:

- Steel framing machine – Efficient production of pre-punched roofing sections.

- Automatic purlin machine manufacturing– Fast, precise, and cost-effective purlin production.

- Construction roll forming – Strong structural profiles designed for building projects.

- Pre-punched steel sections – Ideal for quick assembly and reduced on-site labor.

- Structural steel profiles – Reliable beams and support systems for heavy-duty use.

Metal framing solutions – Suitable for both light and heavy framing applications.

Read more: Combined steel framing machine

SPECIFICATIONS AND EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

| SPECIFICATION | |

| Items | Details |

| Total power | 5.5 – 7.5kw |

| Speed | 3 – 5m/min |

| Dimension (LxWxH) | (18 – 20) x (1.6 – 1.8) x 2.2m |

| Weight of machine | 7 – 10 tons |

| Station quantity | 12 – 16 pairs |

| Thickness of material | 0.6 – 1.5mm (G300-G550) |

| Roller material | Cr12 steel |

| Coil width | Follow drawing |

| Transmission system | Hydraulic motor |

| Cutting system | Hydraulic motor |

| Control system | Automatic with PLC, HMI, Inverter |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | DELTA (Taiwan) |

| Electric motor | HITACHI/HYOSUNG/TECO/ENERTECH |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Cutting blades | SKD11 (Japan) |

| Electric components | YUKEN (Japan) |

| Rollers | S45C, SKD11 (Japan) |

Are you ready for a new generation in your factory?

Contact us now!

WHY CUNMAC MACHINERY?

OUR ADVANTAGES

FACTORY AREA 3000M2

CUNMAC factory is located in Thuan An district, Binh Duong province with a full range of machines and equipment for processing services at the factory.

FULL TYPES OF PROCESSING MACHINE

The company has fullsets of large and medium-sized production equipment so we are committed to controlling the whole production process and serving you the best quality and after-sales service.

MORE THAN 80 STAFF AND TECHNICIANS

Experienced engineers and technicians in professional operation management team will bring customers satisfactionin products and services.

INNOVATIVE DEVELOPMENT

With continuous improvement and innovation over the years, we have become one of the global manufacturers to ensure high quality and excellent customer services.

RICH EXPERIENCE

More than 15 years dedicated to mechanical production with rich experiences of different types of machines all over the world.

EXPERIENCE TO WORK WITH DIFFICULT MARKETS

The company’s products are exported to more than 50 countries and regions such as the the USA, Korea, Australia, Middle East, Uruguay, France, India, Sri Lanka, Myanmar, Malaysia, Indonesia, Thailand, Vietnam, etc.

RELATED PRODUCTS