Go with Cunmac – Before checking out 5 must-have machines for your new roofing factory, let us take a quick look at how to start your own roofing Business while avoiding the mistakes.

- Plan Not to Fail. With all the lists of what to do, what to get and where to get it, how come more new roofing businesses fail than succeed? Avoid error #1.

Hire an accountant. - Know Before You Go. It’s vital to see how much it’s going to cost before you start your roofing business. Only then will you know how much you’ll need to stay afloat and turn a profit.

Establish costs and pricing. - Protect Yourself. Select sole proprietorship, partnership, corporation or LLC (limited liability company). Consult your accountant and your insurance agent.

Register, license and insure your roofing business. - Don’t Overspend. A desk in your spare room, basement or garage and a phone in your pocket will get you rolling. Buy tools only as roofing jobs require them.

Ignore new equipment when used will do. - Recruit Wisely. You want roofers who know at least as much about roofing as you do. You’ll most easily find them in and around roofing supply stores.

Hire the best and fire the rest. - Sell Well. Your future depends on how well you sell. Honing your sales skills at every opportunity is time well spent. The better you are, the bigger you’ll be.

Create a great looking sales kit. - Promote Without Advertising. There are lots of things you can do before spending on advertising. Entire businesses have been built on truck and lawn signs.

Invest in your signage. - Don’t Bite Off More than You Can Chew. Learn from those who’ve been there, done that. Pursue only low-liability jobs you know you can do profitably.

Decline high-risk work.

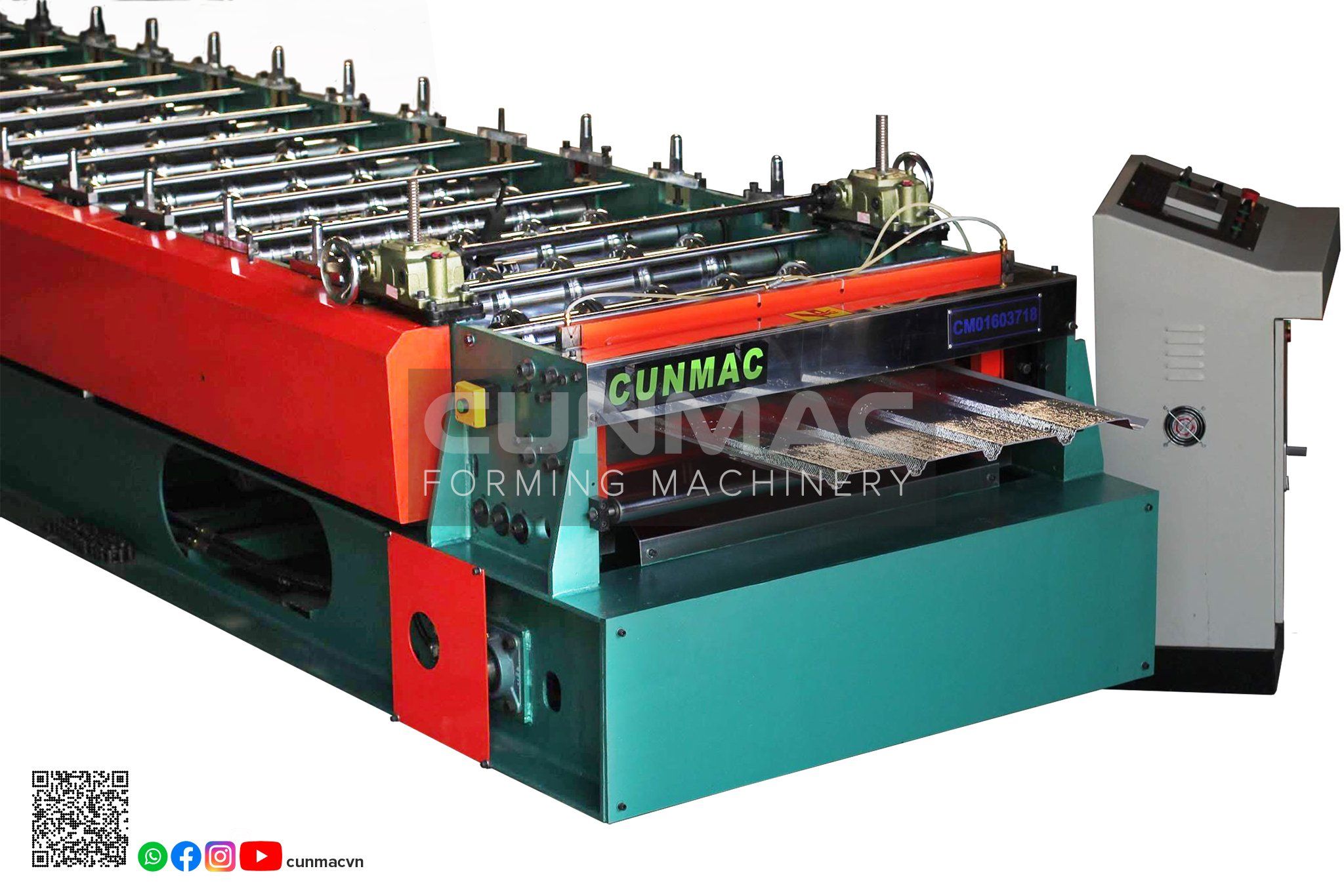

SET 5 MUST-HAVE MACHINES IF YOU WANT TO OPEN A NEW ROOF FACTORY

| Total power | 5 – 22kw |

| Speed | 16 – 46m/min |

| Dimension (LxWxH) | (9-11)x(1.6-2.2)x1.8m |

| Weight of machine | 6 – 12 tons |

| Roller station | 16 – 24 |

| Material thickness | 0.15 – 0.7mm (G300-G550) |

| Material width | 914;1200;1219;1450mm |

No.2: 4 arc crimping forming machine/ Pressing curve machine

| Total power | 3.7 – 7.5kw |

| Speed | 20 – 24step/min |

| Dimension (LxWxH) | 1.3×2.3×1.7 |

| Weight of machine | 1.7 – 2.0 tons |

| Operation option | Vertical & horizontal (manual/cylender) |

| Material thickness | 0.15 – 0.5mm (G300-G550) |

| Material width | 300 – 457mm |

| Total power | 5.5 – 15kw |

| Speed | n/a |

| Dimension (LxWxH) | (3.2-8)x(1.4-2.2)x2.6m |

| Weight of machine | 4.0 – 12 tons |

| Pressing die | SKD11 steel |

| Material thickness | 0.2 – 2.0mm (G300-G550) |

| Length of material | 100 – 8000mm |

| Pressing system | Hydraulic |

| Total power | 5.5 – 11kw |

| Speed | 20 – 30m/min |

| Dimension (LxWxH) | 3.0x(1.0-1.6)x1.4m |

| Weight of machine | 2.0 – 4.0 tons |

| Slitting blade | 3-10 sets |

| Material thickness | 0.15 – 2.5mm (G300-G550) |

| Material width | 914 – 1450mm |

No.5: Decoiler/ Uncoiler

| Total power | 5.5 – 15kw |

| Speed | 0 – 40m/min (adjustable) |

| Dimension (LxWxH) | 2.2×1.2×1.2m |

| Weight of machine | 2.0 – 4.0 tons |

| Material thickness | 0.2 – 2.0mm (G300-G550) |

| Coil width | 450 – 1500mm |

Thank you our customer to choose Cunmac Machinery as your partner to start your business!

Cunmac Vietnam – Leading quality roll forming machine manufacturer from Vietnam!

—————————————————————–