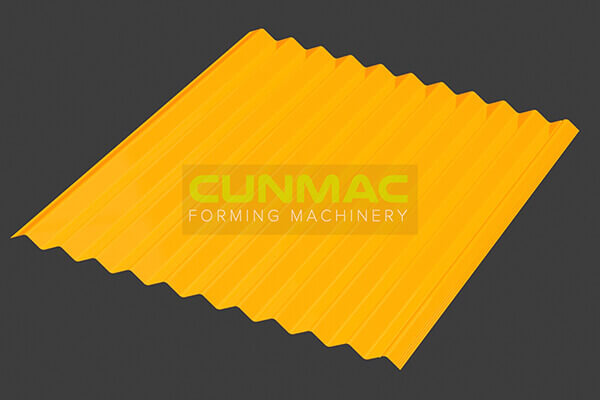

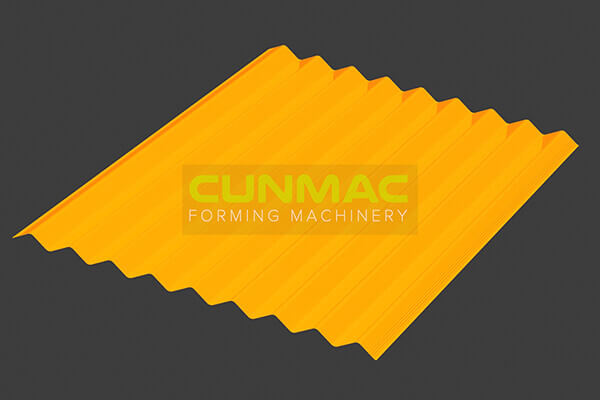

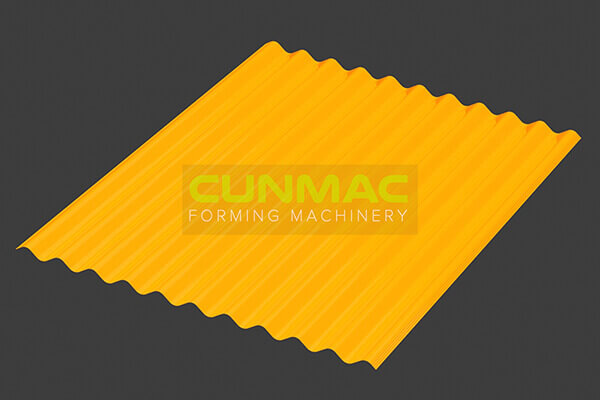

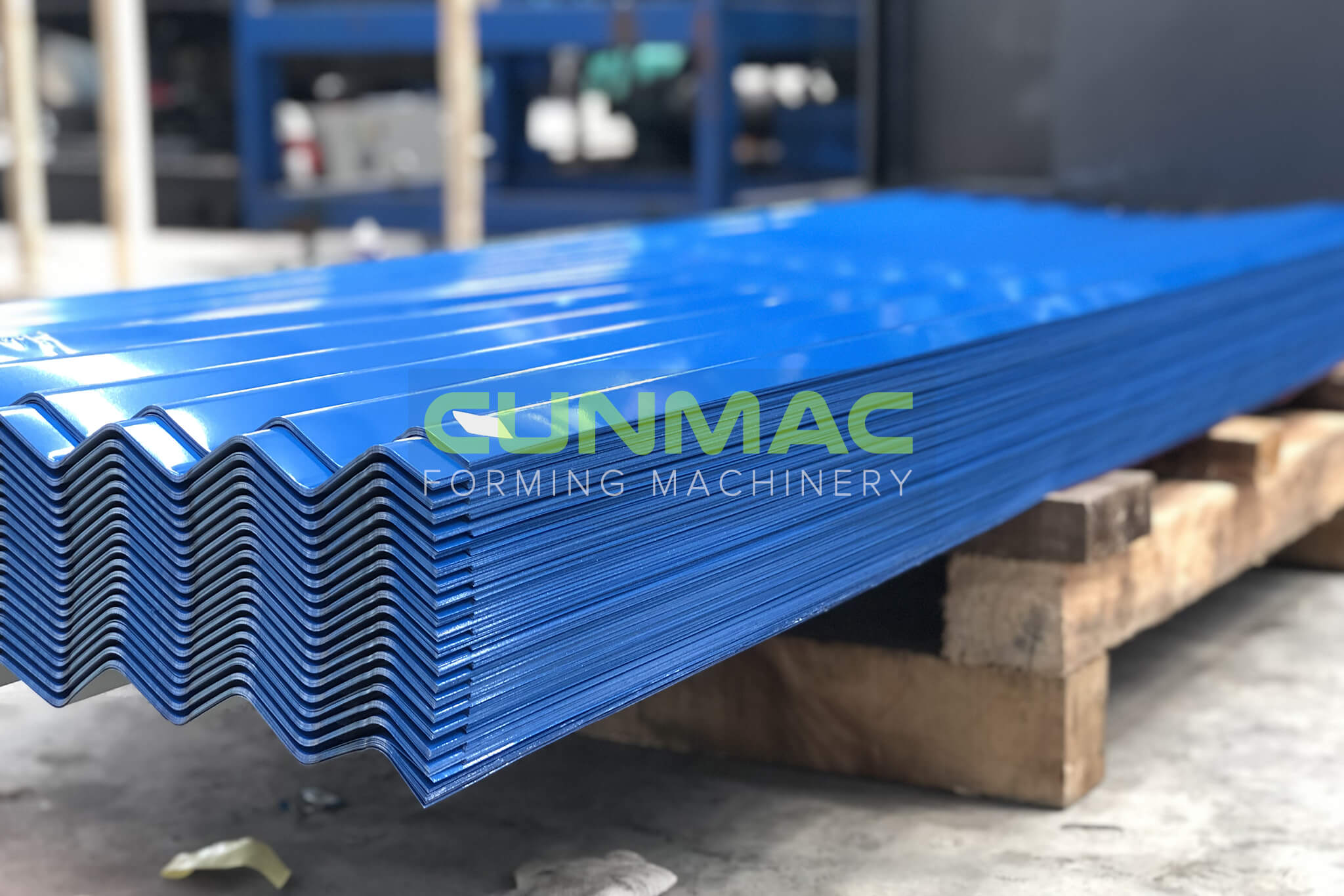

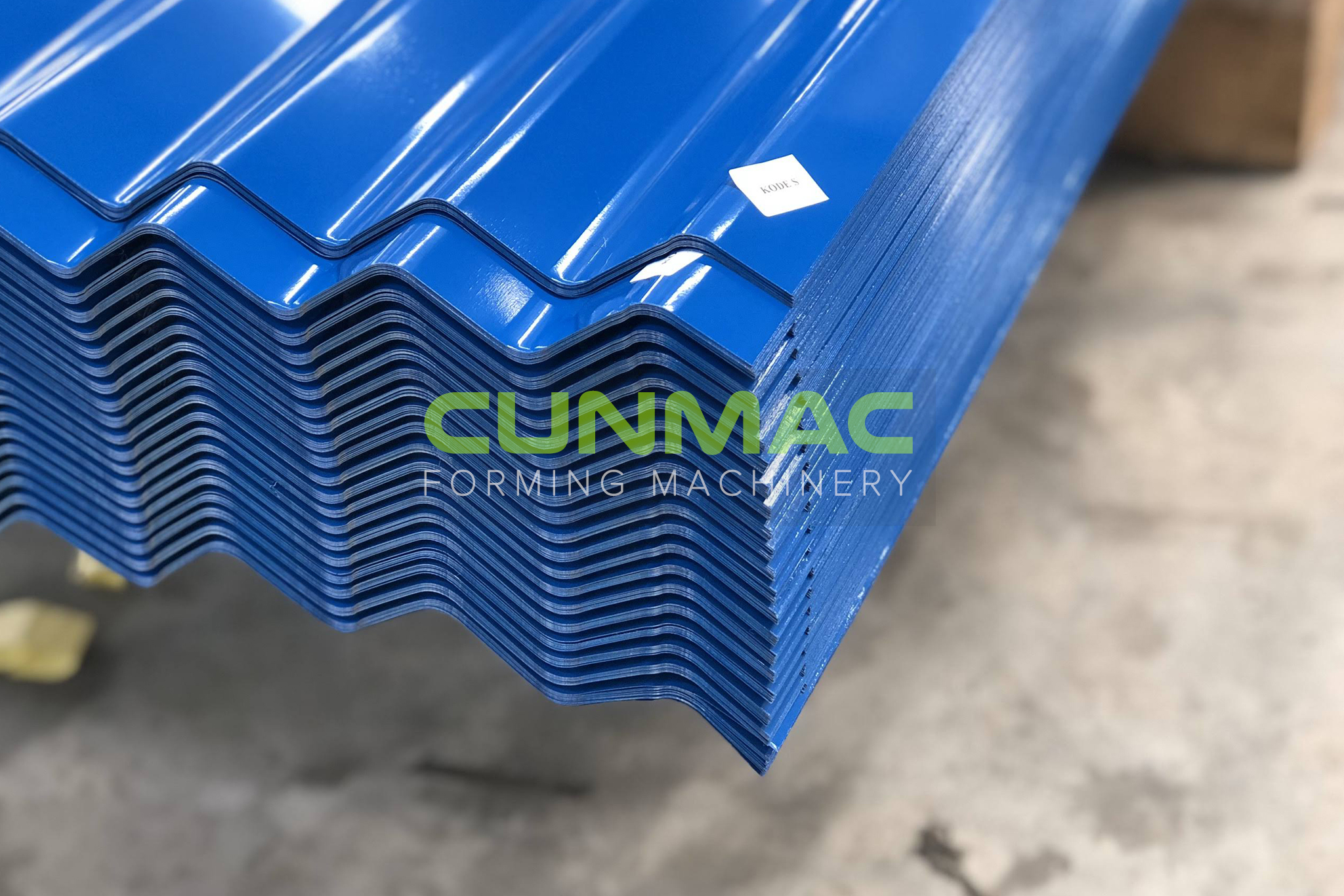

What is a corrugated roofing sheet?

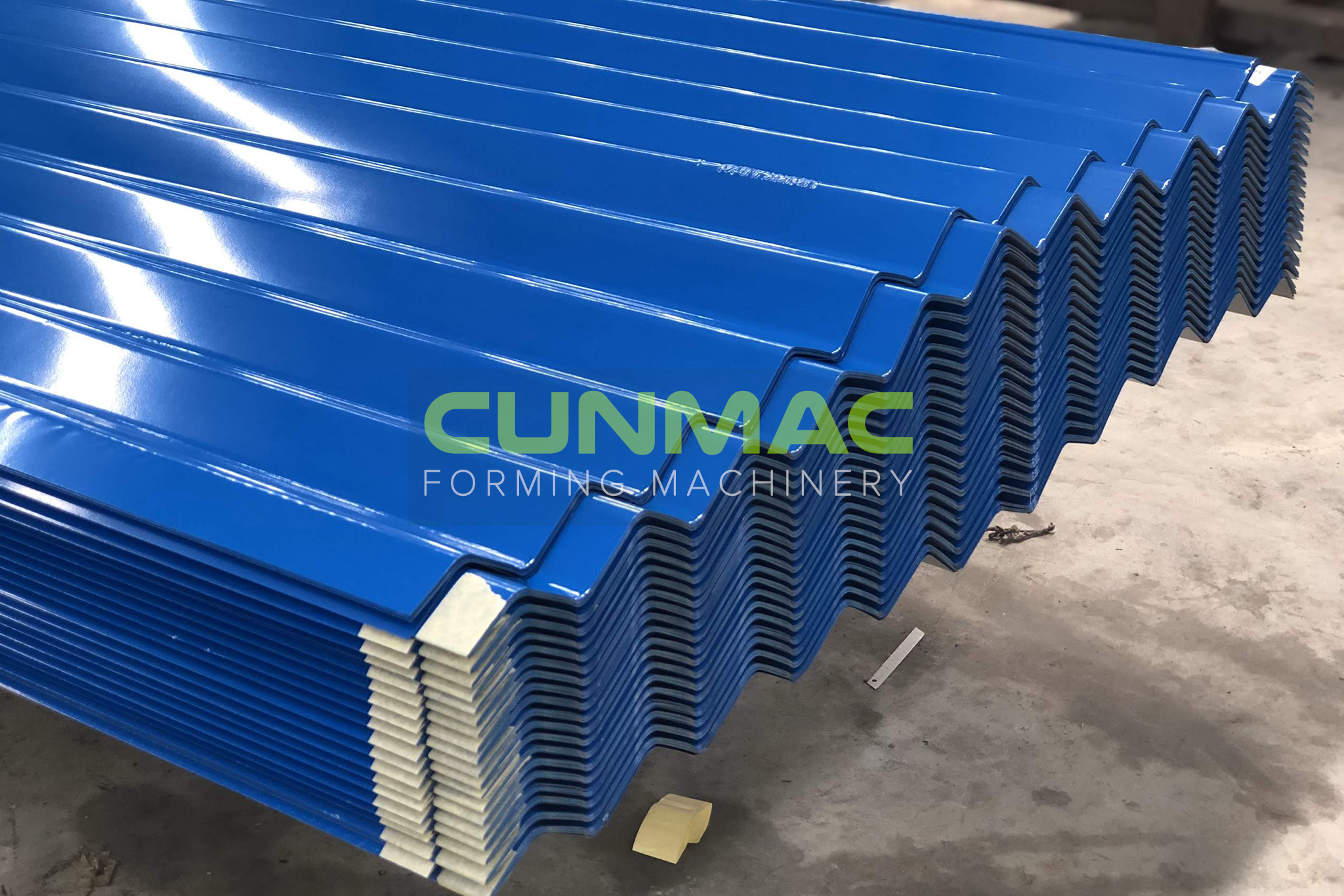

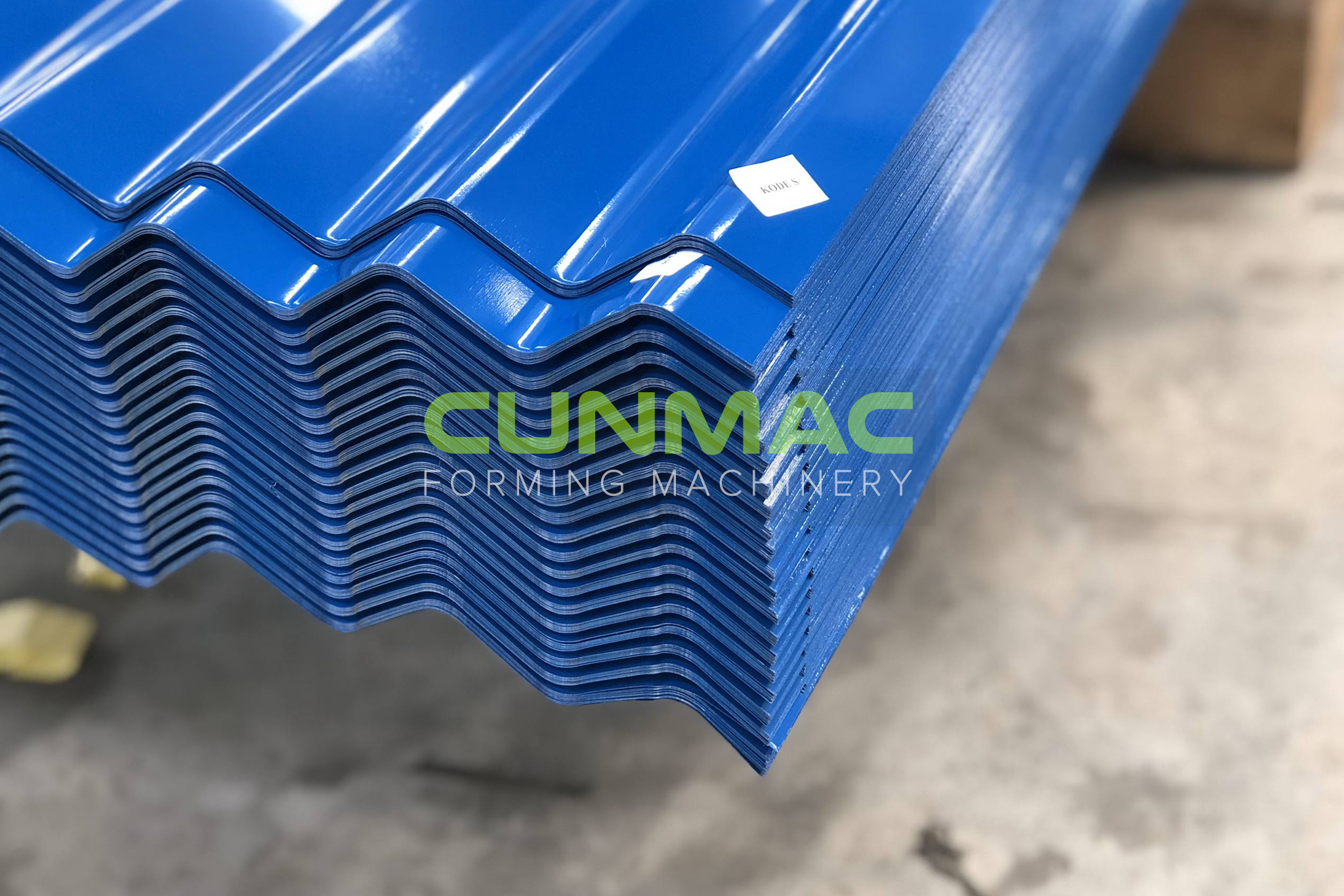

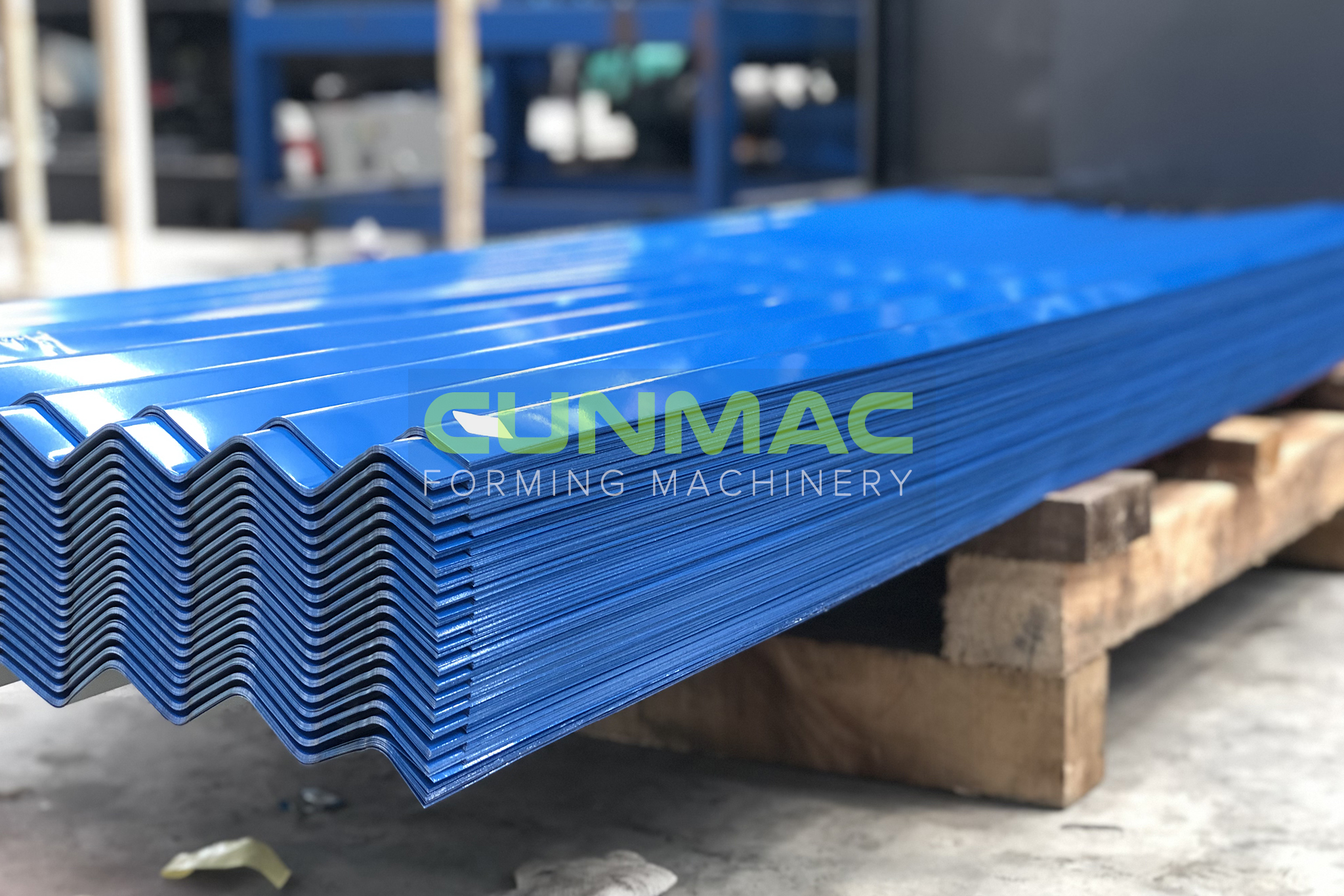

Corrugated metal roofing sheets are commonly used for roofing in a wide range of applications including roofing, wall cladding, fences, and screens.

Household constructions such as houses, kiosks, shops, restaurants, etc,…;

Industrial workshops such as warehouses, factories, offices, …;

Public buildings such as hospitals, clinics, schools, commissars, departments, theater or amusement parks.

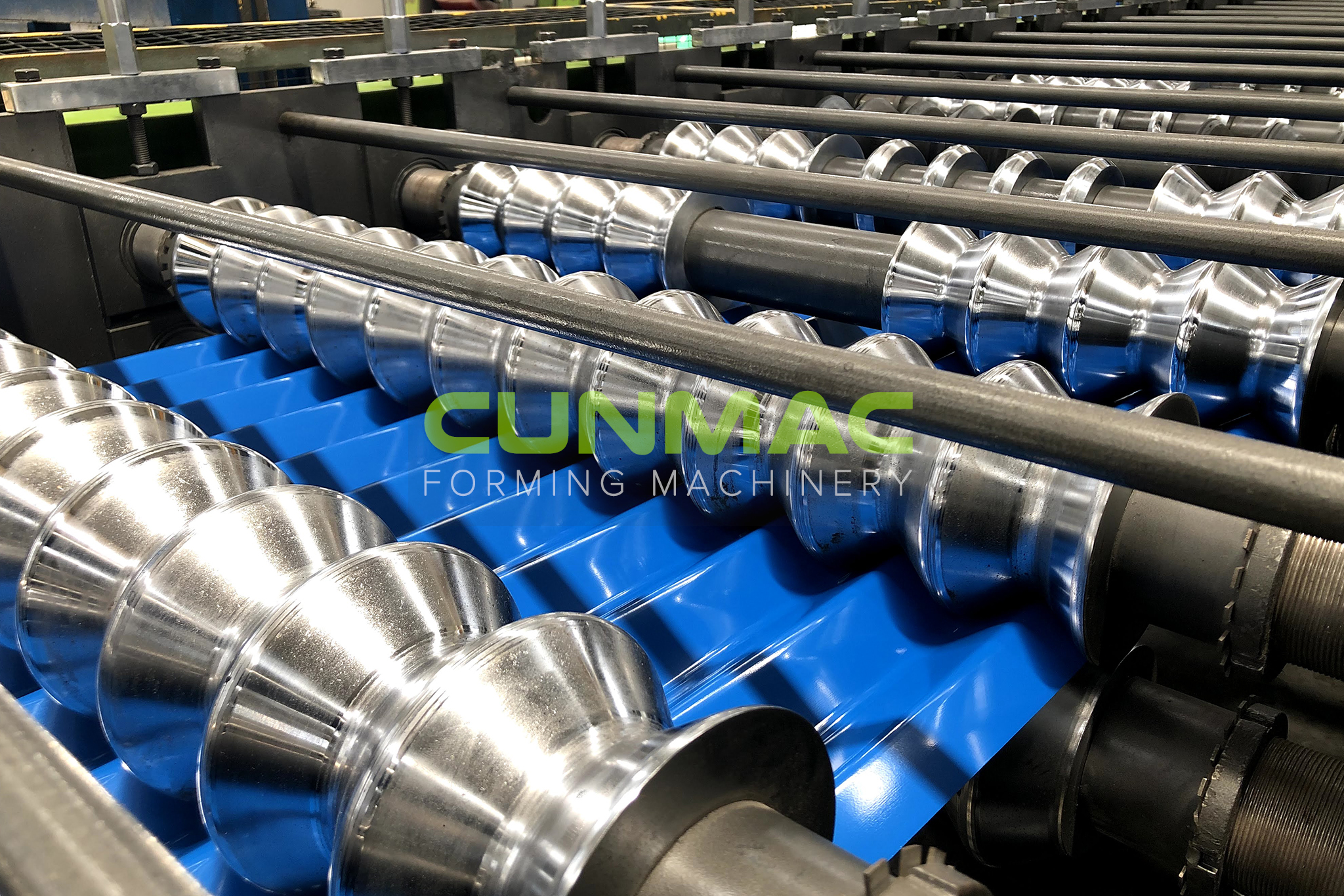

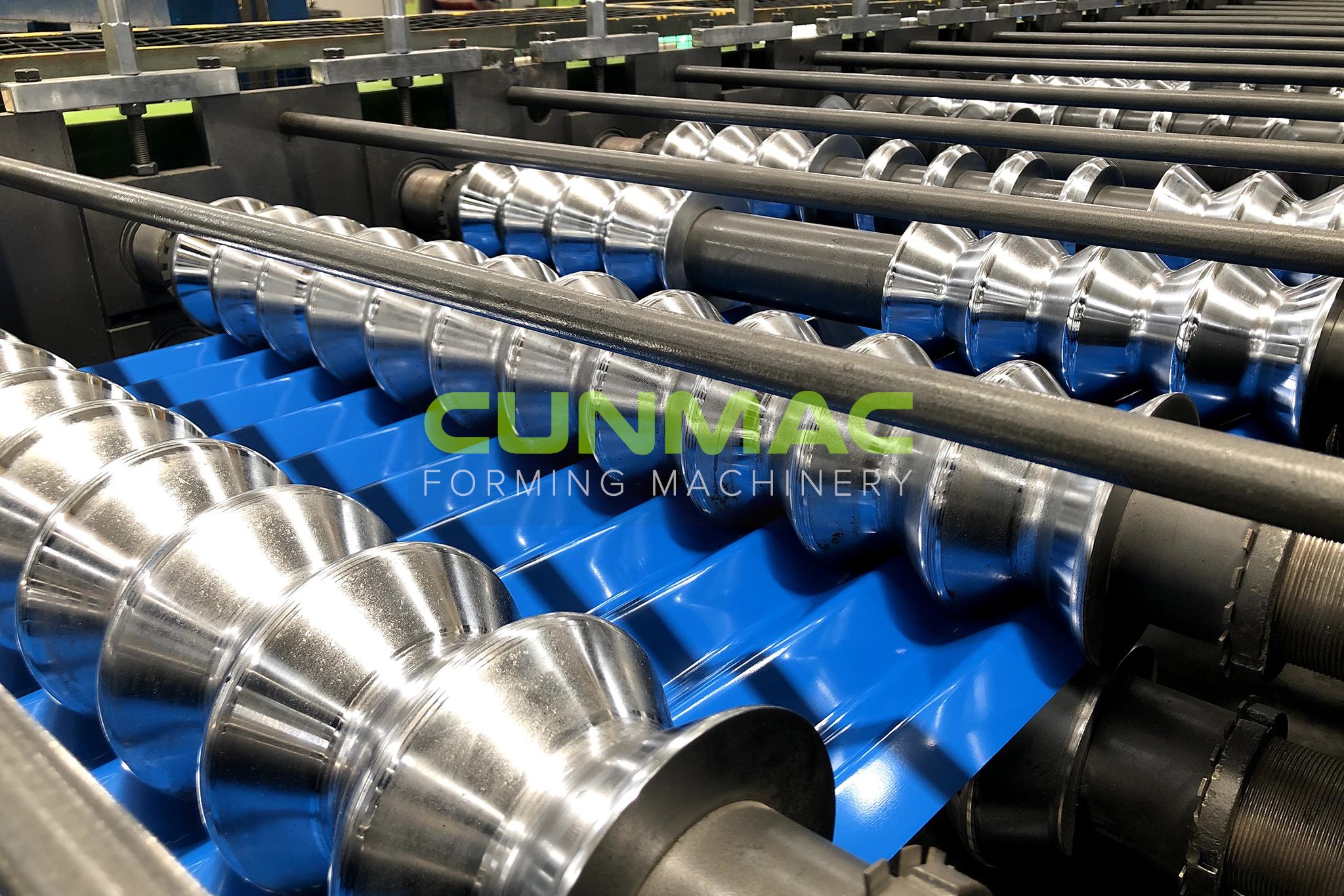

The corrugated metal sheet is designed into rolls, 1200mm flat, is put into the corrugated roll forming machine

Read more: Why corrugated metal roll roofing machine is best-seller?

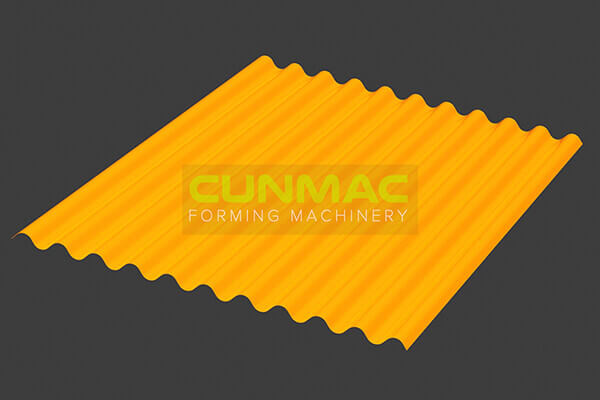

Outstanding advantages of corrugated metal roofing

– After rolling, the useful gauge when roofing with 1 wave is 1000mm, making it easy to calculate the number of sheets and the length.

– The circular wave design helps the corrugated iron cross section in contact with rainwater is low, so it reduces noise perfectly, and is well insulated.

– Zinc, cold and colored corrugated iron are all rolled round corrugated iron

– The average thickness of corrugated iron from 0.30mm (3 dem) to 0.50mm (5 dem) helps people have many choices for many different uses.

– Specification, cutting length as required

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |||

| Items | ECO model | STANDARD model | HIGH SPEED model |

| Total power | 5.5 – 7.5kw | 7.5 – 11kw | 11 – 22kw |

| Speed | 16 – 18m/min | 22 – 24m/min | 44 – 46m/min |

| Dimension (LxWxH) | (9-11)x(1.6-2.2)x1.8m | (10-12)x(1.6-2.2)x1.8m | (11-14)x(1.6-2.2)x1.8m |

| Weight of machine | 9 – 11 tons | 9 – 12 tons | 10 – 14 tons |

| Roller station | 22 – 26 | 26 – 30 | 30 – 36 |

| Material thickness | 0.15 – 0.6mm (G300-G550) | 0.15 – 0.6mm (G300-G550) | 0.15 – 0.6mm (G300-G550) |

| Material width | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm | 914; 1200; 1219; 1450mm |

| Transmission system | Hydraulic motor | Hydraulic motor | Electric motor with gear box |

| Cutting system | Hydraulic cylinder (front cutting) | Hydraulic cylinder (rear & front cutting) | Electric motor with gear box (rear & front cutting) |

| Control system | Automatic with PLC, HMI | Automatic with PLC, HMI, Inverter | Automatic with PLC, HMI, Inverter |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

Cunmac proudly provides Corrugated roofing roll forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.