DETAILED INFORMATION

Slitting and cutting to length machine combines slitting and shearing functions, making it versatile for cutting and shearing operations in the metal slitting and sheet metal shear sectors. Slit and shear/cut to length machine is widely used in the metal plast, laser cutting, and sheet metal industries.

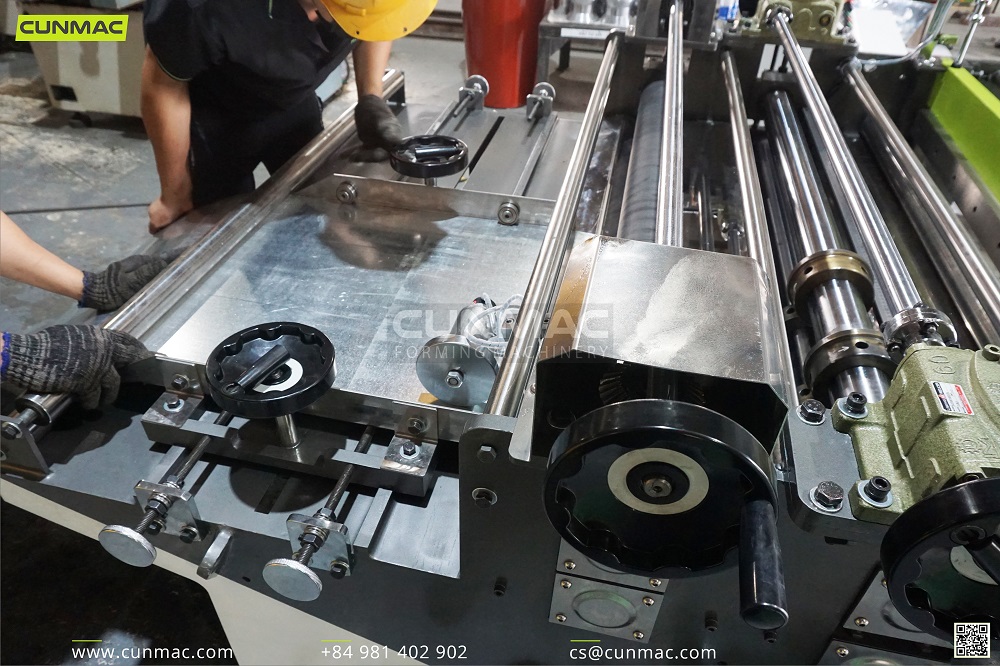

Slitting and Shearing/Cutting to length machine

advantages

Portability

Both the slit machine and slit and shear machine are highly portable, allowing for easy transportation and setup in various locations for maximum convenience.

Cost-Efficiency

These machines are a cost-effective solution in the slitting line and cut-to-length line markets, offering excellent value without compromising quality.

Global Trust

Equipped with top-tier components from Japan and Germany, they are quality-controlled and trusted in over 30 countries in the steel slitting and hydraulic metal shear industries.

Warranty and Service

Backed by a 2-year warranty and 24/7 sales service, these machines ensure long-term reliability in slitting and shear brake roll applications.

MACHINE VIDEO

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Roller and blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | |

| Items | STANDARD model |

| Total power | 5.5 – 11kw |

| Speed | 20 – 30m/min |

| Dimension (LxWxH) | 3.0x(1.0-1.6)x1.4m |

| Weight of machine | 2.0 – 4 tons |

| Slitting blade | 3 – 10 sets |

| Material thickness | 0.15 – 2.5mm (G300-G550) |

| Material width | 914; 940; 1200; 1219; 1450mm |

| Transmission system | Hydraulic |

| Shearing system | Hydraulic |

| Control system | Automatic with PLC, HMI |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

APPLICATIONS

Slitting and cutting to length line application

Full line: Auto decoiler >> Slit and Shear/Cut to length machine >> Recoiler

Recoiler and Slit & Cut to length machine

Slit & Shear machine and Auto decoiler

SPECIAL DISCOUNT

Unlock exclusive savings – Fill this form to join our discount program today!

[contact-form-7 id=”31966″]ABOUT CUNMAC MACHINERY

ABOUT CUNMAC MACHINERY

CUNMAC products are distributed across more than 30 countries over the world, including America, France, Korea, Australia, India, Angola, Ethiopia, Ivory Coast, Thailand, Myanmar, Indonesia, Malaysia, Sri Lanka, Kuwait, Cambodia, and Vietnam, among others.

We offer a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.