What are the differences between I-beam and H-beam? Are they only used in construction? Let’s jump into this post to find out now!

WHAT IS A BEAM? WHAT IS A BEAM USED FOR?

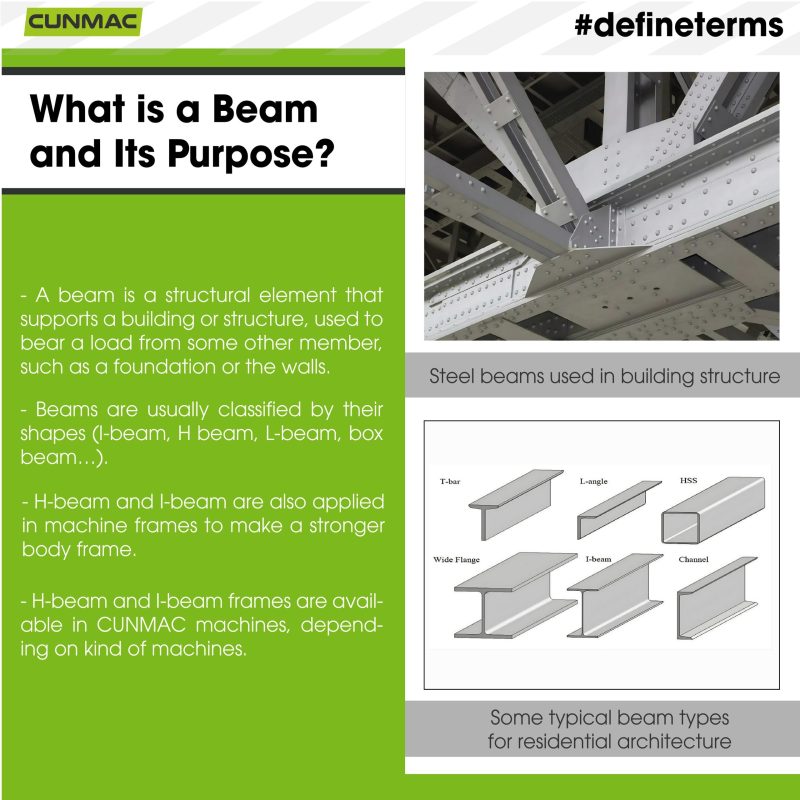

A beam is a structural element that supports a building or structure, used to bear a load from some other member, such as a foundation or the walls. Steel beams are usually classified by their shapes (I-beam, H-beam, L-beam, box beam…).

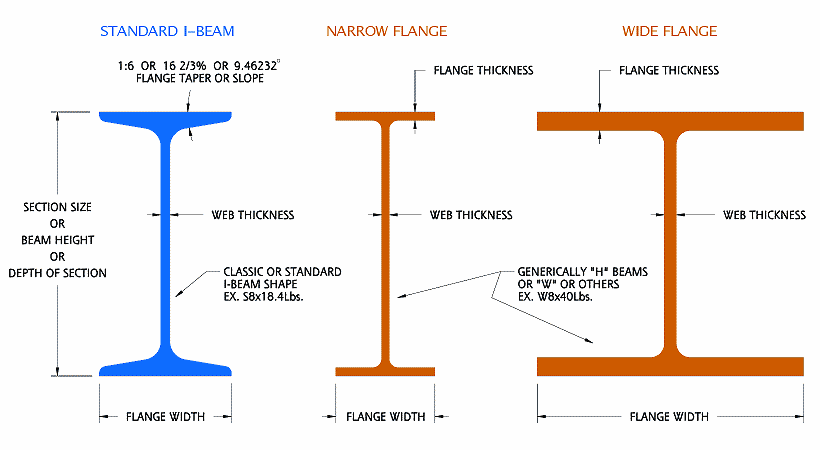

The most common steel beam is the I-beam. The beam consists of two flat horizontal surfaces known as flanges connected by a horizontal element referred to as a web. Its cross-section resembles a capital letter I with serifs, therefore the name I-beam. When positioned horizontally, it takes on the shape of a capital letter H, and is also known as an H-beam.

Steel beam and its applications

In making machine framings, H-beam and I-beam are popular choices to make a stronger body frame.

At CUNMAC, depending on the kind of machine, I-beam or H-beam will be used flexibly and properly for the machine frame. Some kinds of machines provided: roofing/wall cladding/decking roll forming machine, truss/purlin roll forming machine, profile roll forming machine…

Base frame and wall frame of CUNMAC machines

DIFFERENCES BETWEEN I-BEAM AND H-BEAM

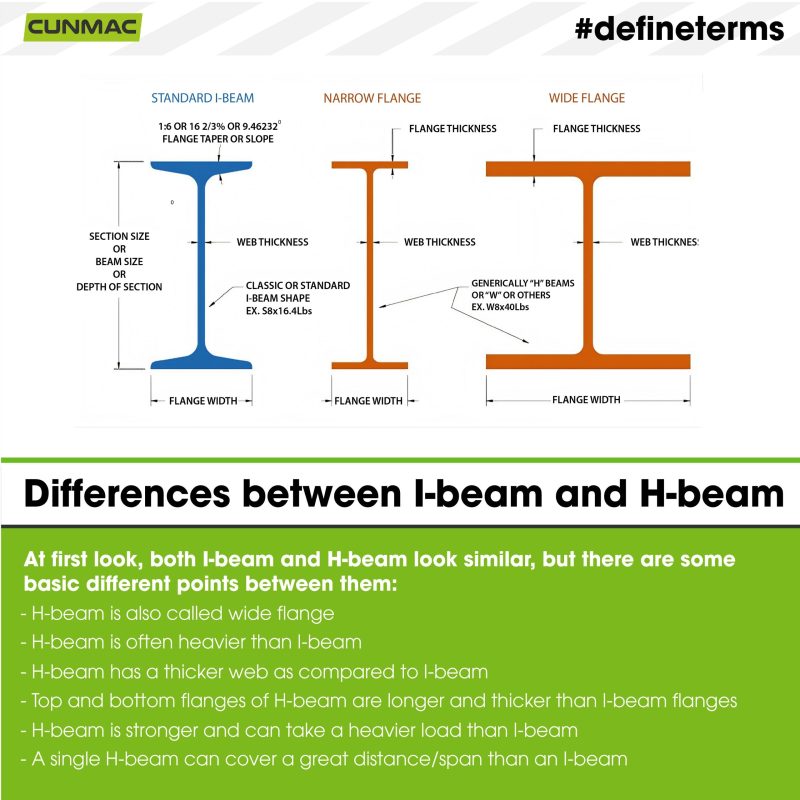

At first look, they look similar, but there are some basic different points between them:

– H-beam is also called wide flange

– H-beam is often heavier than I-beam

– The web of an H-beam is thicker compared to an I-beam

– Top and bottom flanges of H-beam are longer and thicker than I-beam flanges

– H-beam is stronger and can take a heavier load than I-beam

– A single H-beam can cover a great distance/span than an I-beam

I-beam and H-beam in comparison

Through this post, CUNMAC team has given you basic differences between I-beam and H-beam you need to know. Don’t forget to follow the next issue of our series #defineterms to update more useful information.

This series belongs to CUNMAC Vietnam.

CUNMAC Vietnam – Innovative engineering machine manufacturer (OEM), to customize design and provide solutions for roll forming machines to over 30 countries in the world.

We customize, design and manufacture a wide range of good solutions and products for companies operating in the sheet metal, construction and manufacturing industries.

All CUNMAC machines are made in Vietnam. Our goal is to provide made-in-Vietnam flexible machines with good ease of use and high quality, where our designs and solutions give customers unique benefits and experience of our products.