High Speed (Non-Stop Cutting) Roll Forming Line with Auto Stacker 12m for America

In today’s highly competitive construction and steel manufacturing industry, production efficiency, accuracy, and automation are decisive factors for success. The High speed (non-stop cutting) roll forming line with auto stacker 12m for America is engineered to meet these exact requirements, offering a powerful, fully automated solution for high-volume steel profile production

This advanced roll forming system is specifically designed for the American market, where large-scale construction projects demand continuous output, consistent quality, and fast delivery schedules. By integrating non-stop cutting technology, intelligent PLC control, and an automatic 12-meter stacking system, this production line significantly enhances productivity while minimizing labor dependency and operational downtime

Overview of the Roll Forming Solution for the American Market

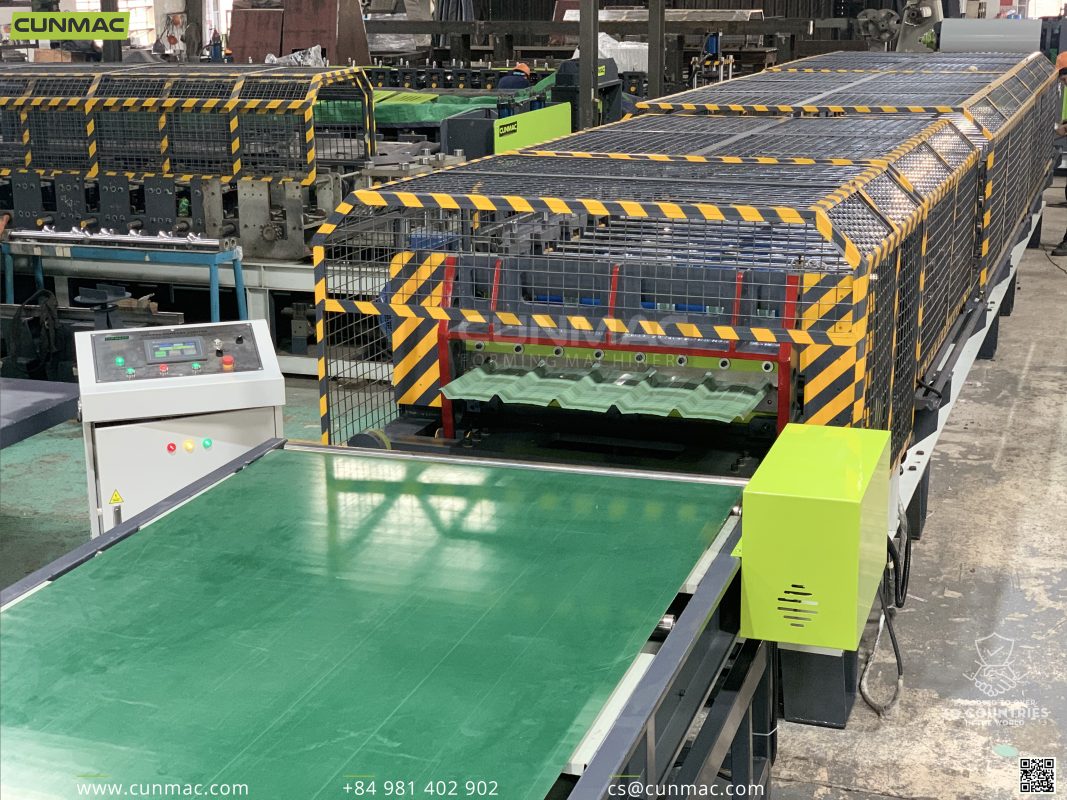

The High speed (non-stop cutting) roll forming line with auto stacker 12m is a complete industrial production system developed for uninterrupted operation. Unlike conventional stop-and-cut machines, this line allows profiles to be cut accurately while the machine continues running at high speed, ensuring a smooth and efficient workflow

The system typically includes a decoiler, feeding unit, precision roll forming stations, hydraulic flying shear cutting unit, PLC control cabinet, and a 12-meter automatic stacker. This integrated configuration is ideal for manufacturers supplying roofing systems, structural components, and cold-formed steel products to large construction projects in the United States

Technical Capabilities and Production Performance

Built with high-grade materials and advanced machining technology, the High speed (non-stop cutting) roll forming line with auto stacker 12m delivers reliable performance even under continuous operation. Roll forming stations are CNC-machined to ensure dimensional accuracy, durability, and long service life

The PLC control system enables operators to precisely set cutting lengths, production speed, and batch quantities. Real-time monitoring and fault diagnostics help minimize downtime and maintain consistent output. The 12-meter automatic stacker aligns and stacks finished profiles neatly, preparing them for packaging or transportation without manual handling

Benefits for Manufacturers Using High-Speed Roll Forming Technology

Implementing the High speed (non-stop cutting) roll forming line with auto stacker 12m provides significant operational advantages. Continuous production dramatically shortens lead times, enabling manufacturers to meet tight delivery schedules for large-scale projects

Automation reduces labor costs while minimizing human error. Precision cutting ensures uniform profile lengths and shapes that comply with American construction standards. Optimized material usage reduces scrap rates, helping manufacturers improve cost efficiency and sustainability

WHY CHOOSE THIS HIGH-SPEED ROLL FORMING LINE?

Choosing the High speed (non-stop cutting) roll forming line with auto stacker 12m means investing in a reliable, future-ready production solution

Non-stop cutting technology

Enables continuous production without line stoppage, significantly increasing output.

High-speed roll forming performance

Ensures stable operation and consistent profile accuracy even at high production rates.

12-meter automatic stacking system

Efficiently handles long profiles, reduces manual labor, and improves workplace safety

Integrated conveyor system

Ensures smooth product transfer and improves overall production efficiency

Reduced labor and operating costs

Thanks to full automation and synchronized system control

Designed for large-scale production

To meet demanding manufacturing requirements in the American market

Is an electric roofing machine a solution you are looking for?

Talk to our expert now!

WORKFLOW AND KEY FEATURES

The production workflow of the High speed (non-stop cutting) roll forming line with auto stacker 12m for America is optimized for efficiency and accuracy.

The line operates in a continuous sequence: Decoiler → Roll Former → Fly-Cut System → Conveyor → Stacker, ensuring smooth material flow and stable production.

Steel coils are unwound and fed smoothly into the roll forming section, where successive rollers gradually shape the material into the required profile.

As the formed steel advances at high speed, the hydraulic flying shear performs precise cuts without stopping the line, after which finished products are transferred via the conveyor and stacked automatically in uniform bundles.

APPLICATIONS OF THE ROLL FORMING LINE

The High speed (non-stop cutting) roll forming line with auto stacker 12m for America is widely used for producing steel purlins that support roofing and wall systems. It is also suitable for manufacturing roofing sheets, structural framing components, fencing profiles, and other cold-formed steel sections.

For manufacturers producing roofing panels and related components, Cunmac also offers specialized machine such as the Electric Roofing Machine, which complements high-speed roll forming lines in roofing production systems

SPECIFICATIONS AND EQUIPMENT

- Automatic roll forming and cutting with Inverter, PLC, HMI

- Automatic programmable length settings via the touch panel

- Blades are fabricated from alloy and SKD11 steel 60-62HRC

- Electrical and hydraulic components made from Japan, Germany

- Save history for orders in 30 days

- Customize design

- Stable operation with strong power and body frame

| SPECIFICATION | |

| Items | HIGH SPEED ROLL FORMING LINE |

| Total power | 7.5 – 11kW |

| Speed | 50 – 60m/min |

| Dimension (LxWxH) | (30 – 33) × 3.0 × 2.2m |

| Weight of machine | 7 – 10 tons |

| Station quantity | 18 – 22 pairs |

| Material thickness | 0.15 – 0.8mm (G300-G550) |

| Material width | 914; 940; 1200; 1220; 1250mm |

| Cutting system | Flying shear, non-stop cutting |

| Control system | Automatic with PLC, HMI |

| Transmission system | Hydraulic motor/Gear motor |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | SCHNEIDER (Japan) |

| Electric motor | HITACHI/HYOSUNG/TECO |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Cutting blades | SKD11 (Japan) |

| Electric components | YUKEN (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

| Hydraulic components | YUKEN (Japan) |

Are you ready for a new generation in your factory?

Contact us now!

WHY CUNMAC MACHINERY?

OUR ADVANTAGES

FACTORY AREA 3000M2

CUNMAC factory is located in Thuan An district, Binh Duong province with a full range of machines and equipment for processing services at the factory.

FULL TYPES OF PROCESSING MACHINE

The company has fullsets of large and medium-sized production equipment so we are committed to controlling the whole production process and serving you the best quality and after-sales service.

MORE THAN 80 STAFF AND TECHNICIANS

Experienced engineers and technicians in professional operation management team will bring customers satisfactionin products and services.

INNOVATIVE DEVELOPMENT

With continuous improvement and innovation over the years, we have become one of the global manufacturers to ensure high quality and excellent customer services.

RICH EXPERIENCE

More than 15 years dedicated to mechanical production with rich experiences of different types of machines all over the world.

EXPERIENCE TO WORK WITH DIFFICULT MARKETS

The company’s products are exported to more than 50 countries and regions such as the the USA, Korea, Australia, Middle East, Uruguay, France, India, Sri Lanka, Myanmar, Malaysia, Indonesia, Thailand, Vietnam, etc.

RELATED PRODUCTS