Curved metal roofing panels offer an unbelievably unique approach to roofing solutions. Whether for commercial buildings or residential homes, radiused metal roofs create a distinct look. The panel’s flexibility and adaptability allow designers, architects, and homeowners to get creative when it comes to roofing.

WHAT IS A CURVED ROOF?

Many different techniques and materials have been used to create curved roof types throughout history. While curved roofs can also be built using tiles and shingles, modern curved roofs frequently use metal roofing materials because of their flexibility. Curved surfaces, curved peaks, and softly tapering roof edges are all possible with metal sheets twisted in this fashion.

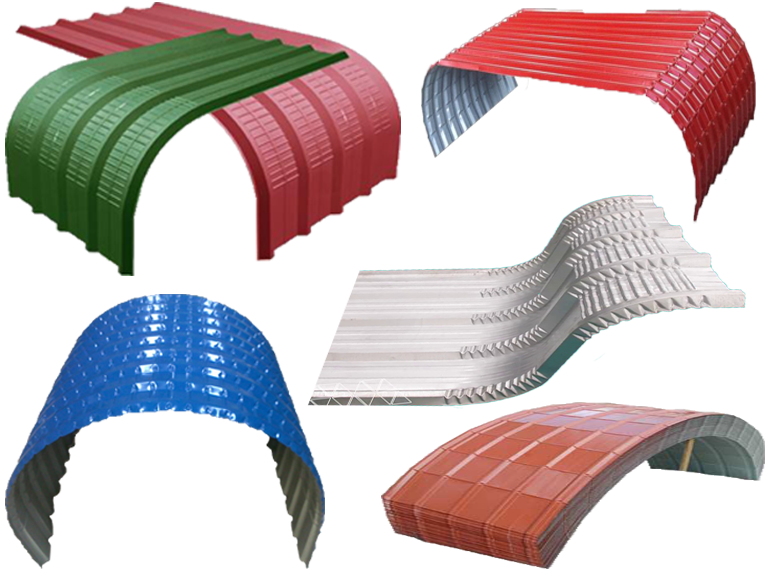

Curved roofs come in a number of shapes and sizes, and can include a variety of concave and convexed features as needed.

WHICH PANELS CAN BE CURVED?

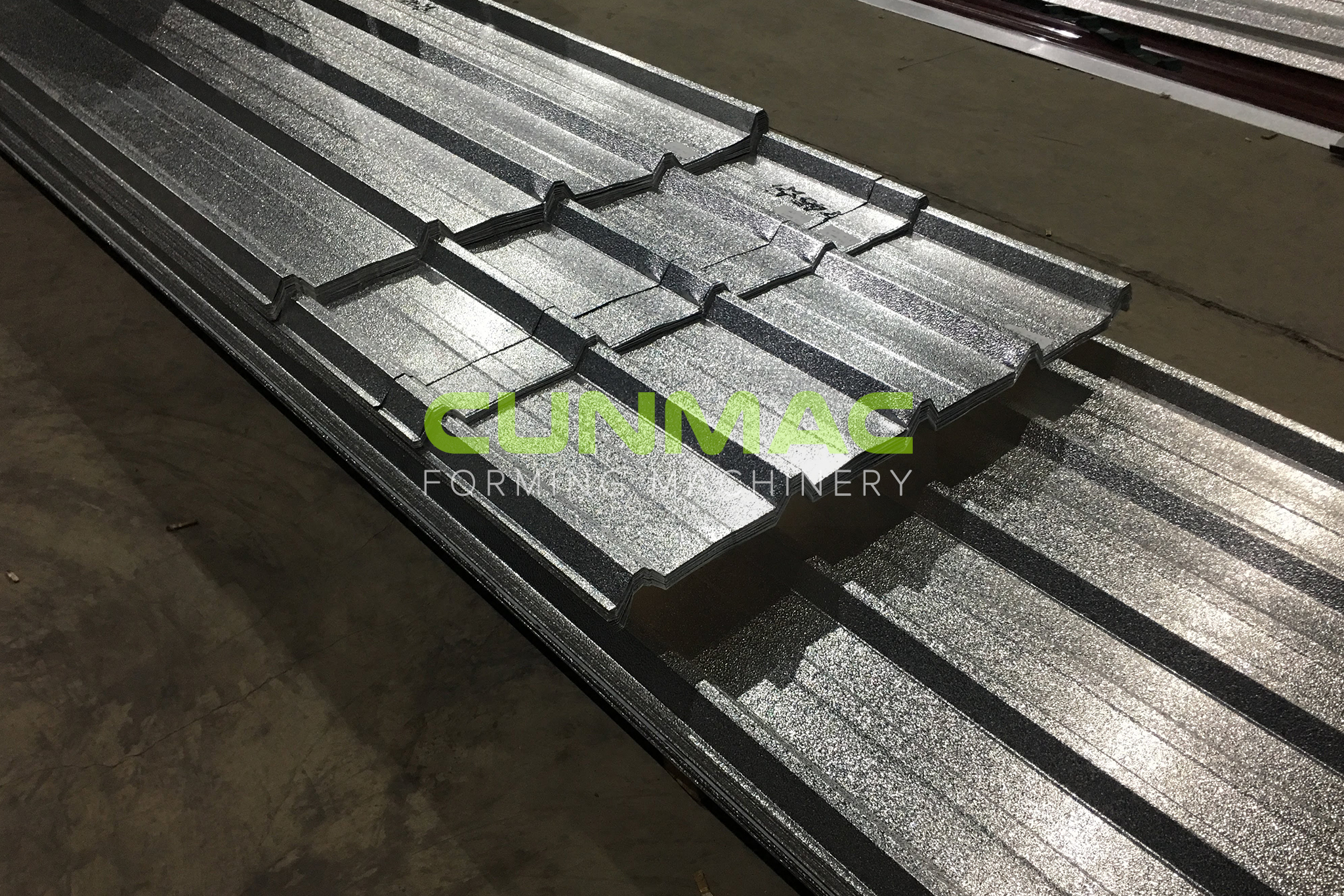

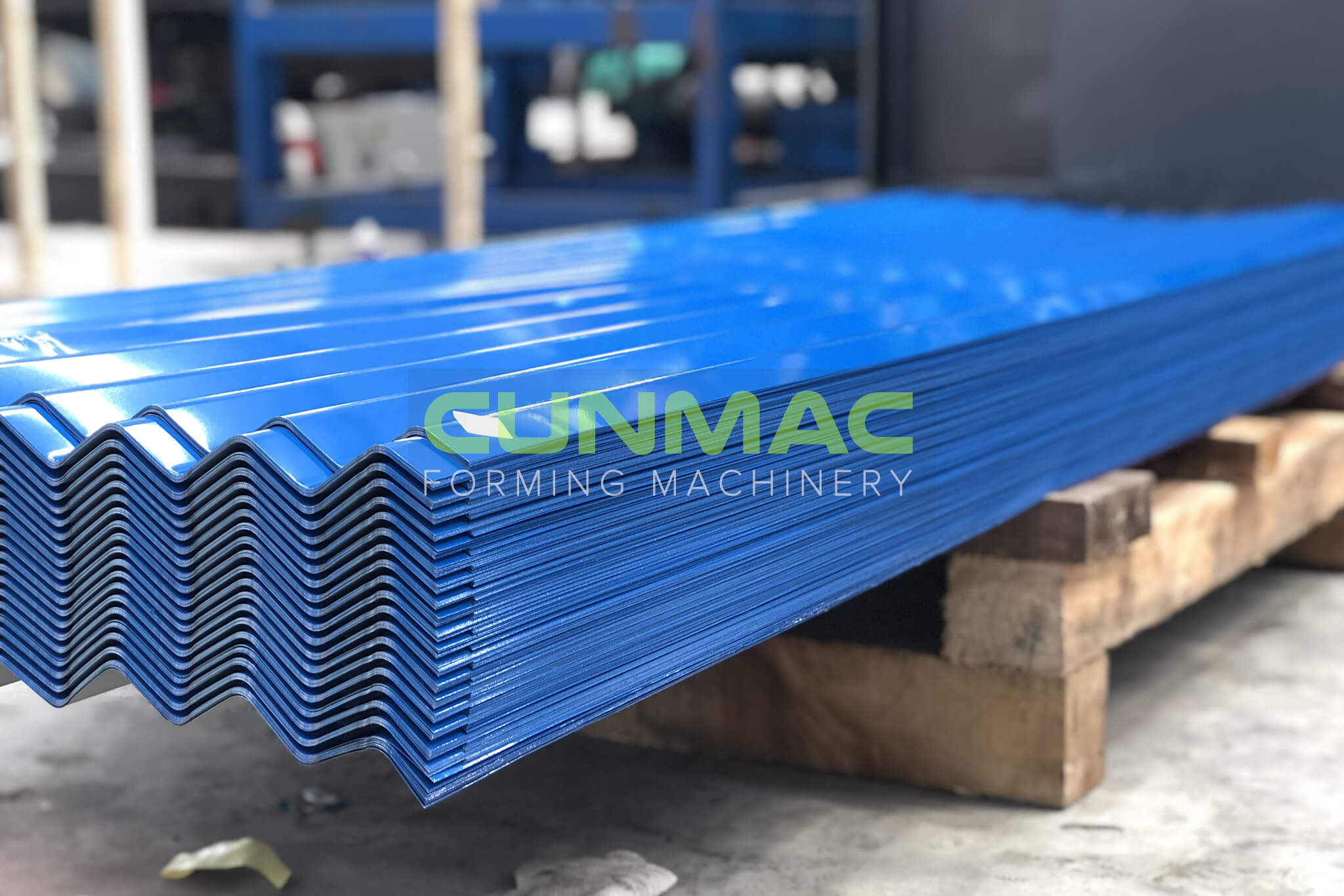

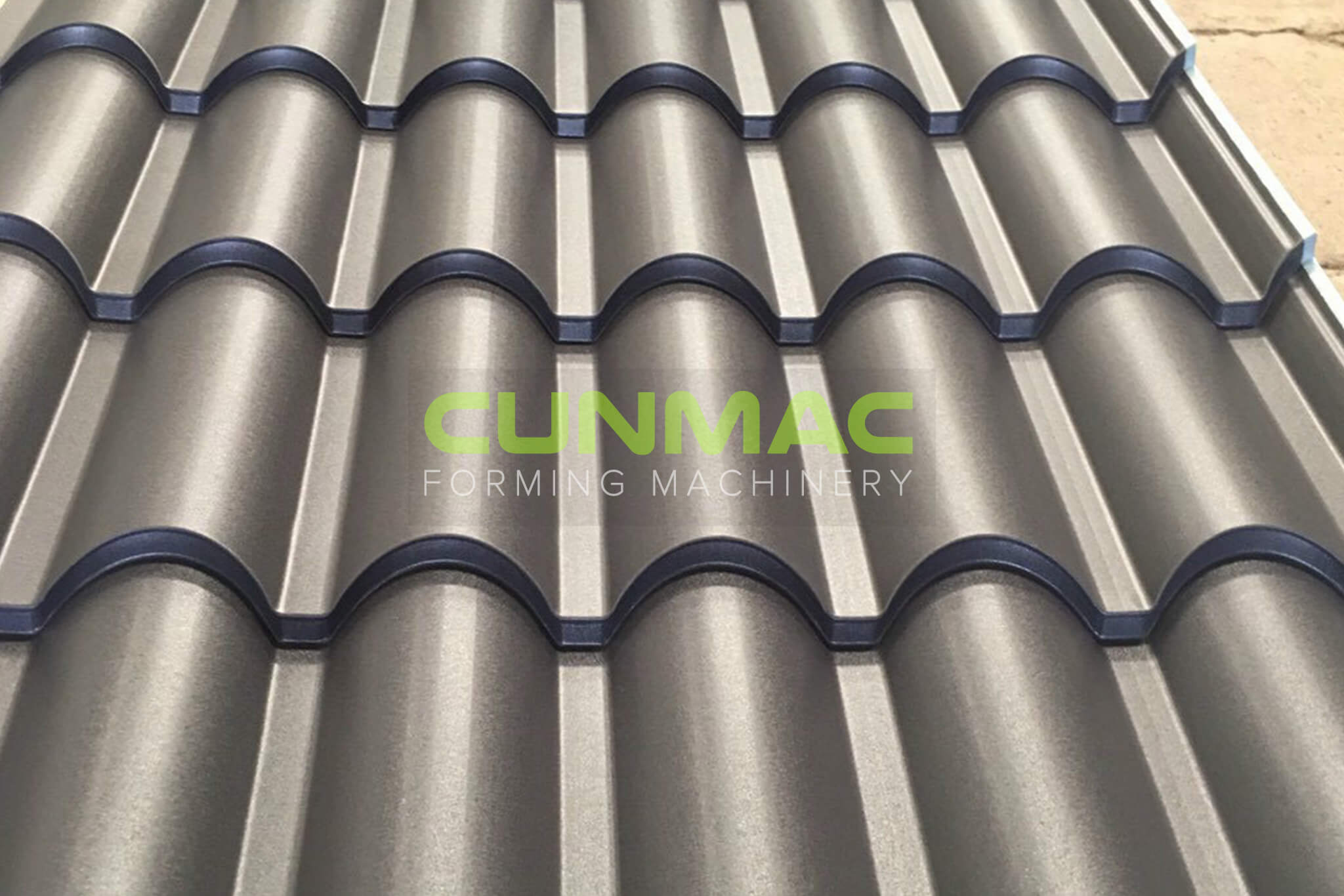

Most types of roofing sheets can be curved such as Trapezoidal roofing sheet, Corrugated roofing sheet, Metal roof tile or even lockseam or standing seam profile.

BENEFITS OF CURVED METAL ROOFING

Curved metal roofs have a number of advantages, the most notable of which being the distinctive look they provide, as well as the predicted durability and longevity of metal. Here are a few of the numerous advantages of curved metal roofing:

- Beautiful Aesthetics — One of the most obvious advantages of curved roofs is the eye-catching appearance they provide. Our eyes are naturally drawn to curved roofs because they have a visual attraction. A curved roof produces a variety of forms, textures, and angles that are attractive to the eye and help a structure or residence stand out. One of the most significant advantages of a curved roof is its atypical, modern style.

- Curved roofs may help a building or house owner make the most of every inch of available space. Curved roofing eliminates the need for high slopes, allowing you to make the most of every square inch of your home or business.

- Longevity and Durability — Curved metal roofs are equally as long-lasting as regular metal roofs. The same high-performance, robust attributes may be expected, as well as similar longevity (40-70+ years). Because of its robustness, metal is an excellent roofing material, and curved metal roofs are no exception!

HOW IS A CURVED ROOF MADE?

When it comes to creating curved metal panels for roofing, there are three different ways a sheet of metal can be radiused.

Natural Curve — Metal panels can curve naturally (within reason) when the panels are placed over a large area or radii. Without any extra strains or force, the weight of the panel will naturally drop down and conform with the substrate. If there are smaller, tighter areas, the panels can be forced down and secured with clips.

Crimp Curve — Crimp curving is an ideal method for sheet metal that extends past the roof of a building. This method creates a softer, less sharp-looking edge. This is achieved by pressing a series of indentations into the panel in order to fit the surface or radii, and allows for tight curves to be created.

Mechanical Curve — Mechanically curving panels is probably the most common method. It starts with a flat, straight panel that’s then fed into a machine that repeatedly uses rollers to stretch/compress it into the desired look. This method is typically used when the curve is much tighter than what can naturally occur.

CRIMP CURVING MACHINE – PRESSING CURVE FORMING MACHINE – CUNMAC VIETNAM

Common names: Curving machines/ Crimp Curving Machine/ Crimping machine/ Crimp-curve roll forming machine/ Roof sheet crimping machine/ Sheet metal crimping machine/ Crimp curved roofing sheet making machine.

With this machine, users can make a variety of curve profile sheets upon customers’ requirements also called as Crimp Curved Roofing Sheets / Curving Sheets / Curved sheet Metal roofing/ Convex Curved Sheets/ Cladding Curved Sheets/ Ridge Curve Sheets.

There are 3 types of curving machines for steel roof panels including:

- Standard pressing curve forming machine/ Crimp Curving Machine

- Double pressing curve forming machine (concave & convex)

- Combine pressing & cutting curve forming machine

Now that you understand how the curving roofs are made. If you are concerned about a Crimp curving machine, Our sales reps have decades of experience with roll forming machines and would be happy to assist you. For more information on different types or you are ready to purchase please contact our consultant today.

To give a better quotation and meet exactly your requirements, could you advise detailed information as below:

- Which kind of roof roll forming machines do you need?

- Profile or sample’s pictures

- Thickness and width of coil

Who is CUNMAC?

As a global manufacturer of roof panel roll forming machines with over 15-year experience, CUNMAC believes in building partnerships and provides comprehensive customer services.

Through resources, innovative solutions and expert service, we are committed to a stable production with good quality and great services. CUNMAC products have been trusted and used by customers all over the world, which demonstrates CUNMAC’s reliability and trustworthiness.