What is a Crimp curving machine – pressing curve forming machine?

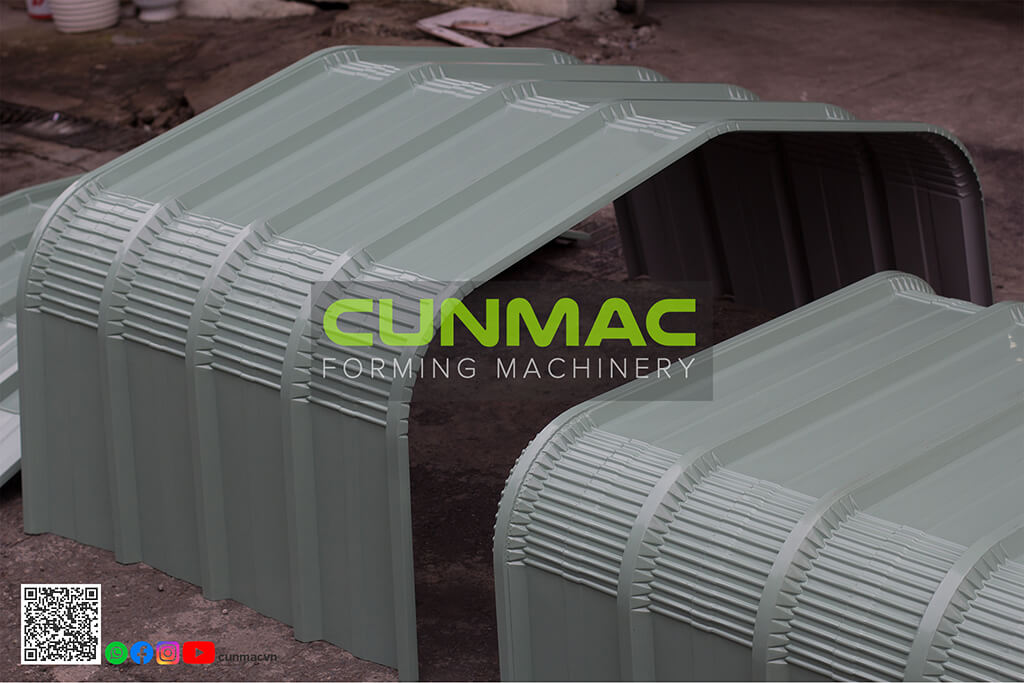

Crimp curving machine is used to press trimdek/spandek/4 angles/waves/ribs type/trapezoidal curved into an arch, for roofing in the eaves to make crimp curved roofing sheets

There are 3 types including:

Standard pressing curve forming machine/ Crimp Curving Machine

Double pressing curve forming machine (concave & convex)

Combine pressing & cutting curve forming machine

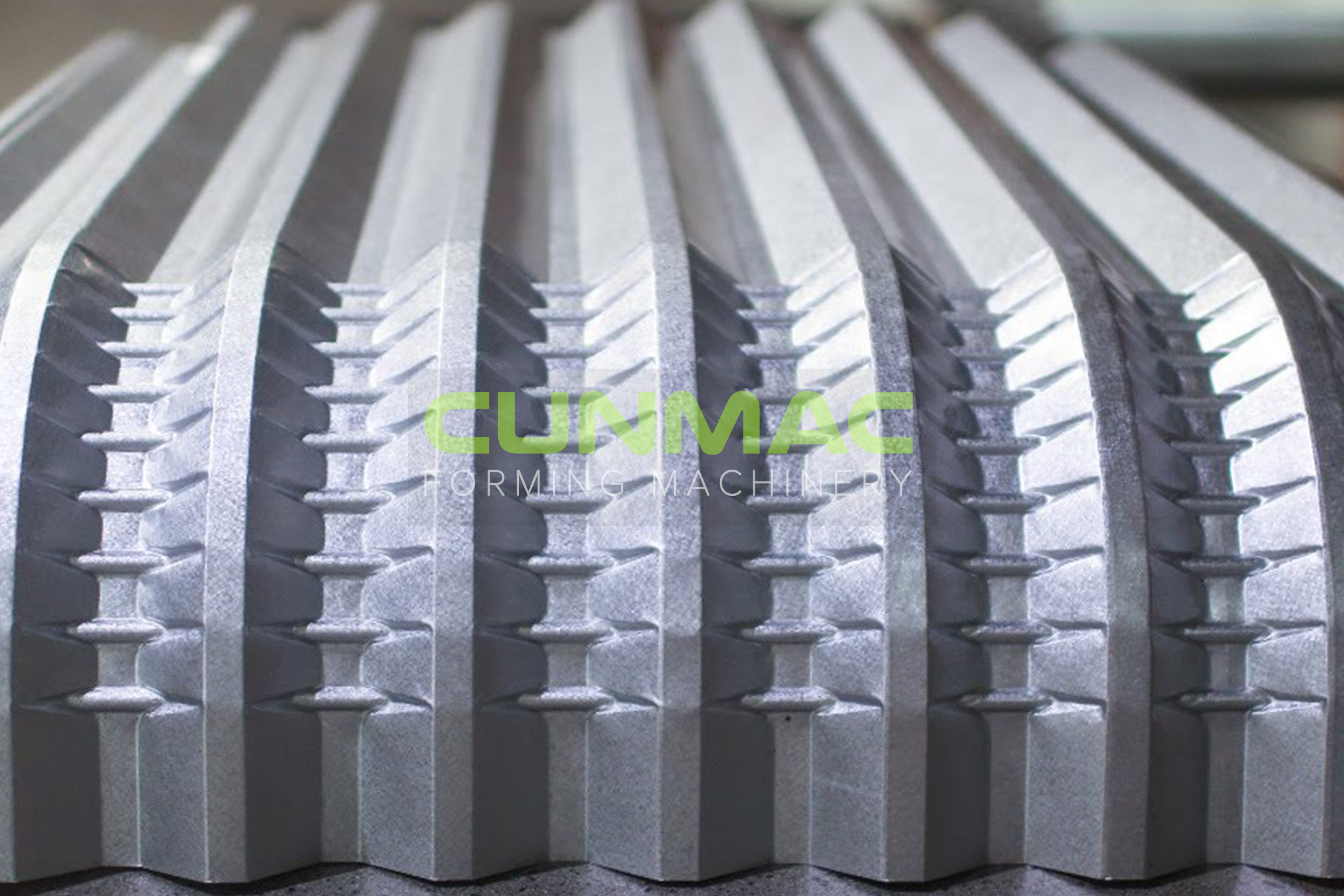

Pressing Curve Forming Technology

The machine applies a step-by-step pressing method, distributing force evenly along the length of the sheet. This forming approach allows the metal to bend naturally into the required curvature radius without excessive stress concentration

As a result, the pressing curve forming process minimizes risks such as profile flattening, material deformation, surface scratches, or coating cracks. This makes the machine especially suitable for high-end architectural roofing systems where both appearance and precision are critical

Technical Performance and Control System

The crimp curving machine is equipped with a PLC and HMI control system, allowing operators to easily set curvature parameters according to different roofing profiles and project specifications. Curving depth, radius, and pressing sequence can be adjusted precisely to ensure repeatable results

With a rigid machine structure and synchronized pressing mechanism, the machine delivers stable performance during continuous operation, even when processing long panels or varying material thicknesses

WHY CHOOSE THIS PRESSING CURVE FORMING MACHINE?

Multiple profile capability

Supports trimdek/spandek/trapezoidal, corrugated, rib-type, and customized roofing profiles on a single machine

High-precision pressing accuracy

Ensures smooth and consistent curvature while maintaining the original profile shape

Surface and coating protection

Pressing technology minimizes damage to painted or coated metal sheets

Flexible curvature adjustment

PLC-controlled settings allow quick changes for different curvature radii and profiles

Stable performance for long panels

Maintains accuracy even when processing long roofing sheets

Easy integration into production lines

Compatible with existing roll forming and cutting systems

Is an electric roofing machine a solution you are looking for?

Talk to our expert now!

MACHINE VIDEO

APPLICATIONS OF CURVED ROOFING SHEETS

Curved roofing sheets produced by the Crimp Curving Machine – Pressing Curve Forming Machine are widely used in industrial, commercial, and architectural construction projects. The pressing curve forming technology ensures accurate curvature while maintaining the original roofing profile.

In industrial buildings, curved roofing sheets are commonly applied for:

- Factories, warehouses, and logistics centers requiring large-span roofs

- Industrial plants that demand good load distribution and wind resistance

In commercial and architectural applications, curved panels are often used for:

- Arched roofs and curved roof structures

- Canopies, entrances, walkways, and exhibition halls

- Airports, shopping centers, and sports facilities

The ability to curve multiple profiles such as trimdek/spandek/trapezoidal, corrugated, and rib-type sheets provides architects and builders with greater design flexibility while ensuring structural reliability

PRODUCT VALUE AND FINICHED PRODUCT ADVANTAGES

The pressing curve forming process preserves the original profile geometry, resulting in curved roofing sheets with uniform curvature and high dimensional accuracy. This improves installation efficiency and overall roof alignment.

Key advantages of the finished product include:

- Accurate fitting along curved structures with minimal on-site adjustment

- Improved visual consistency and roof aesthetics

- Reduced material waste and stable production quality

For manufacturers, the crimp curving machine expands product capability, supports customized roofing projects, and increases overall production efficiency and competitiveness

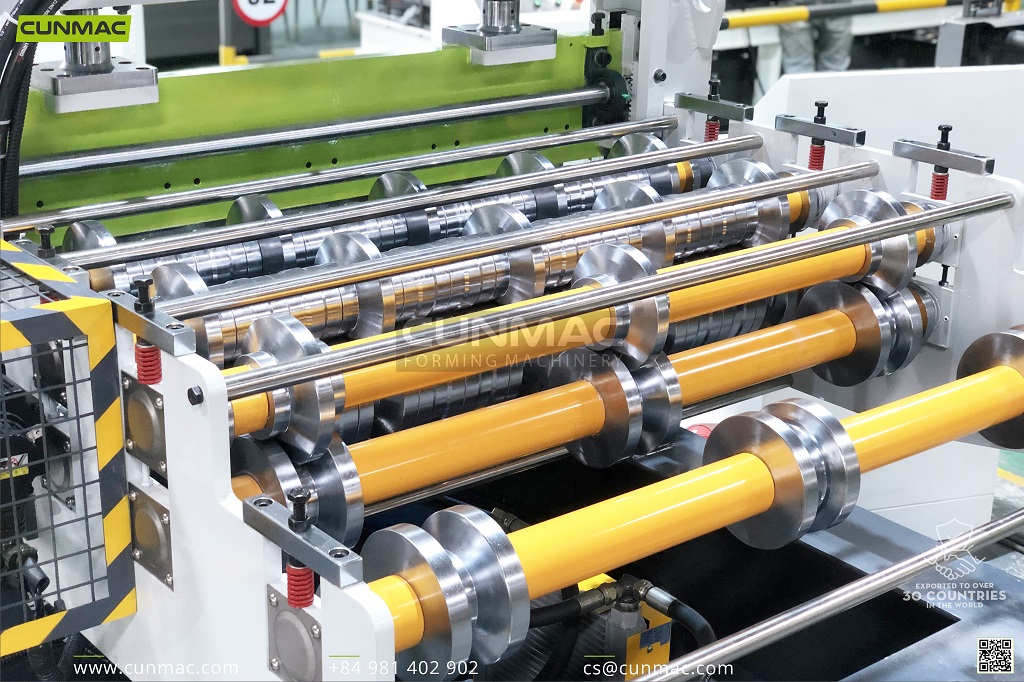

SPECIFICATIONS & EQUIPMENT

– Automatic roll forming and cutting with Inverter, PLC, HMI

– Automatic programmable length settings via the touch panel

– Blade are fabricated from alloy and SKD11 steel 60-62HRC

– Electrical and hydraulic components made from Japan, Germany

– Save history for orders in 30 days

– Customize design

– Stable operation with strong power and body frame

| SPECIFICATION | ||

| Items | STANDARD model | HIGH SPEED model |

| Total power | 5.5 – 7.5kw | 5.5 – 7.5kw |

| Speed | 40 – 44 step/min | 50 – 54 step/min |

| Dimension (LxWxH) | 1.3×2.3×1.7m | 1.3×2.3×1.7m |

| Weight of machine | 1.7 – 2.0 tons | 1.7 – 2.0 tons |

| Operation option | Vertical & horizontal (cylinder) | Vertical & horizontal (cylinder) |

| Material thickness | 0.15 – 0.8mm (G300-G550) | 0.15 – 0.8mm (G300-G550) |

| Material width | 914; 940; 1200; 1219mm | 914; 940; 1200; 1219mm |

| Transmission system | Gear motor | Servo motor |

| Punching system | Hydraulic | Hydraulic |

| Control system | Automatic with PLC, HMI, inverter | Automatic with PLC, HMI, servo |

| EQUIPMENT | |

| Items | Brand |

| PLC (CPU) | SIEMENS (Germany) |

| Touch panel (HMI) | Schneider (Japan) |

| Electric motor | HITACHI/TOSHIBA (Japan) |

| Encoder, relay | OMRON (Japan) |

| Inverter | MITSUBISHI (Japan) |

| Hydraulic components | YUKEN (Japan) |

| Cutting blades | SKD11 (Japan) |

| Rollers | S45C, SKD11 (Japan) |

| Gear box | LIMING (Taiwan) |

ABOUT CUNMAC MACHINERY

Cunmac proudly provides Crimp curving machine – pressing curve forming machine in domestic and international markets including Asia, Australia, Middle East, Africa, America.

About Cunmac Machinery

Cunmac offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

- Roofing roll forming machine

- Caping_Nok roll forming machine

- Louver roll forming machine

- Pressing curve forming machine

- Floordeck roll forming machine

- Truss roll forming machine

- Channel roll forming machine

- Ceiling roll forming machine

- Slitter & cutter

- Leveling & cutting to length machine

- Bending machine

- Decoiler (uncoiler)

All Cunmac machines are professionally and reasonably made in Vietnam, our goal is to provide flexible machines with the best quality and customized designs which give customers unique benefits and experiences.